Sustainability

Pursuing Quality

Basic Approach

Guided by the Corporate Philosophy, which puts customers first, the NGK Group considers the provision of products and services that contribute to a better social environment to be one of its most important missions in attempting to create quality from the customer’s perspective.

The NGK Group engages in the creation of quality from the customer’s perspective by defining Quality Objectives each year in accordance with the Quality Policy based on the NGK Group Corporate Business Principles.

Quality Objectives FY2023

A focus on Organizational Self Discipline is required to improve our “Quality of Operation”.

Results of Initiatives in FY2022

NGK has been implementing quality of operation*1 improvement initiatives since FY2018.

Since FY2021, we have taken efforts to have each person in the workplace strive autonomously to improve the quality of their work. In FY2022 we strove to prevent unreasonable or ambiguous work and ensure thorough communication. As a result, we revised workloads and work rules, promoted understanding and awareness of compliance by workplace and Group companies, and are building an organizational culture in which problems are shared openly.

1 Quality of operation: Level of operational systems that are in place to ensure that promises made to customers are fulfilled.

Initiatives Planned for FY2023

In FY2023 we continue to promote department-led activities so that all members of the NGK Group can refine the quality of operation. To that end, we will maintain the same quality objectives as last year, and work to enhance the autonomy of these activities.

Concerning product quality, we continue to promote QRE-P*2 in our efforts to eliminate quality risks in the market. In particular, we continue to focus on activities that were attempted in FY2022, in which departments analyze the cause of quality issues and strive to improve work process and then instill these in their own activities.

2 QRE-P (Quality Risk Elimination Process): An operational protocol intended to more effectively eliminate quality-related risks at every stage when bringing products to market, from product planning to mass production.

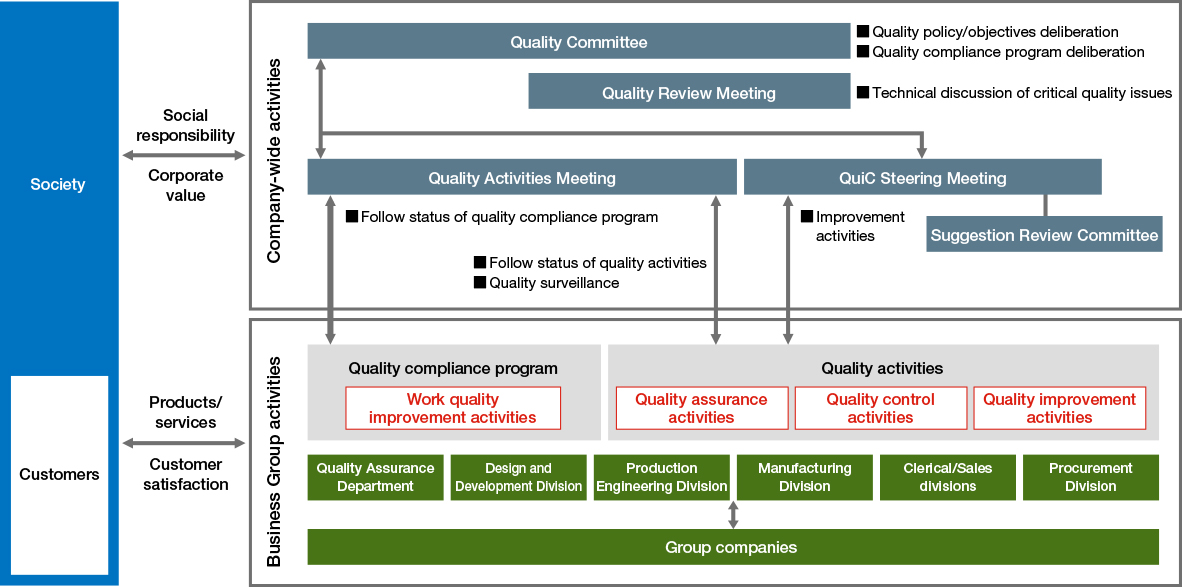

Quality Activity System

The NGK Group quality activity system consists of a company-wide system, led by the Quality Committee Chair, and business division internal activity systems, led by the heads of each business group. In terms of company-wide activities, the Quality Committee was established to function as a deliberative body assisting the Quality Committee Chair, while business division internal activity systems were put in place for each business division, creating appropriate quality systems for each. Quality assurance, quality control, quality improvements, and quality education activities are promoted by the acquisition of ISO 9001 or IATF 16949 certification.

Each business group maintains a point of contact with customers, and works to further increase customer satisfaction by reflecting customer demands and things learned from quality problems in the market in our products and services.

In FY2022, as part of QRE-P, we attempted activities in which departments analyze the cause of quality issues and improve their work processes. We then made operational rules for them to implement when quality issues occur. Our improvements aim to create a work process that will lead to fundamental improvements by having departments in which quality issues occur improve the way they carry out their work.

Quality Activity System

Acquisition of ISO 9001 or IATF 16949 Certification

NGK and the all business group production sites, supporting functions, and locations at Group companies in and outside Japan have acquired ISO9001 or IATF 16949 certification.

Acquisition of ISO 9001 or IATF 16949 Certification

Quality Risk Management

Four Rules for Quality Activities

The NGK Group promotes restructuring of its quality activities to respond more precisely to increasing and diversifying quality demands from customers in different target markets.

We have formulated these quality activity rules particularly to enhance the elimination of quality risks in the market, and are promoting their adoption and improved effectiveness.

Quality confirmation rule

Establish milestones, from development to start of production, and confirm conformance with six quality items when production processes change.

Design Review (DR) function strengthening rule

Register DR plans with quality risks of medium or high level as important DR subjects with participation of company-wide DR reviewers. The Quality Management Department head holds company-wide DRs for cases with a particularly high risk level.

Quality monitoring rule

Monitor and share information company-wide with respect to quality status changes or problems concerning products or markets. Manufacturing defects and customer complaints are shared company-wide every month through reports to the Quality Management Department, and the appropriateness of countermeasures is discussed.

Rule for handling major customer complaints

In the event of a serious customer complaint, including a potential complaint, the situation is promptly reported to the Quality Committee Chair to formulate company-wide countermeasures.

Seeking Greater Effectiveness from Quality Activities and Innovation in Operational Procedures

We have been promoting QRE-P activities throughout the NGK Group. Through these activities, we can identify procedural innovations in product realization in order to eliminate risk while improving quality. Since the start of QRE-P activities in FY2017, we have worked to incorporate the QRE-P concept into quality system in each department, and also have provided practical training so that the person in charge can put QRE-P in practice, using development projects as examples.

In FY2022, we focused on weaknesses in the work processes in each department and continued efforts to incorporate the QRE-P concept into each department's work processes, which began in FY2020. To this end we made rules in which the department analyzes what parts of the work process were lacking and improves their work processes by themselves instead of merely implementing technical countermeasures when problems occurred in the market.

In addition, we began to expand QRE-P activities mainly within Group companies in Japan that carry out product and process design to strengthen our rollout of QRE-P activities to Group companies.

In FY2023, with the aim of more effectively and efficiently eliminating quality risks in development projects, we will join departments in considering quality risks in accordance with QRE-P from an early stage in development as we work to improve reliability at commercialization. Also, in order to further promote QRE-P activities at Group companies, we plan to consider rolling out QRE-P activities to Group companies outside Japan as well.

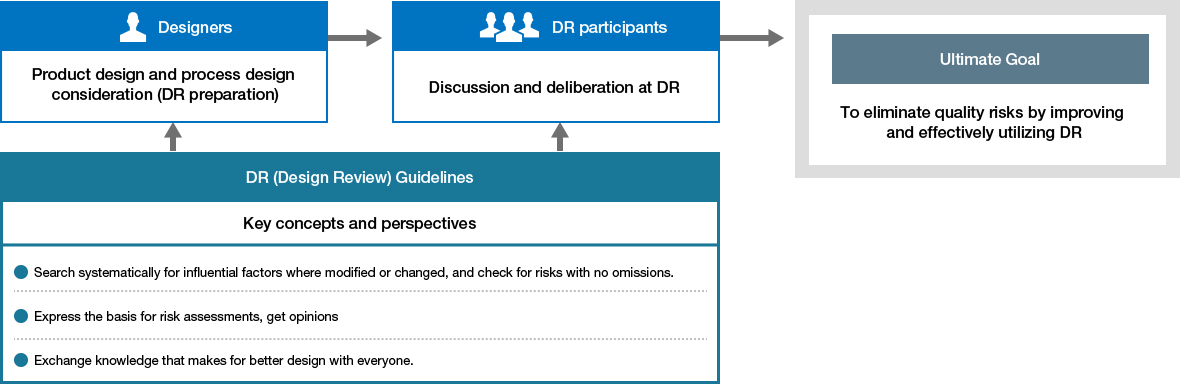

Activities to Strengthen DR Functions

The increasing and diversifying quality demands from customers call for the integration of knowledge among various members throughout the development process, not only from the design department but also from the manufacturing and production engineering departments. For this reason, the NGK Group considers the Design Review (DR) to be the most critical activity. DRs are conducted when development milestones are reached or when production processes change. Critical DRs are conducted by reviewers from throughout the company to support the elimination of quality risks.

The DR Guidelines were created to promote DR discussions and to thoroughly eliminate quality risks. We are constantly enhancing the effectiveness of DRs through efforts to spread these guidelines company-wide, including awareness and review of each DR.

Furthermore, NGK organizes a company-wide DR (quality review meeting) for quality issues that are difficult to solve by one department. At this meeting, relevant engineers and experts from across the company discuss broad aspects of issues related to the reliability and safety of products.

We are also deploying the above-mentioned QRE-P approach to facilitate improvement of design level at the pre-DR period as well as to ensure the more effective utilization of organizational knowledge and experience from DRs.

Quality Activities at Production Bases Outside Japan

From their inception, production bases outside Japan have created quality systems appropriate to their situations and acquired ISO 9001 or IATF 16949 certification.

Monthly reports from each base regarding customer complaints and the status of manufacturing quality are discussed at Quality Activity Meetings, enabling the entire NGK Group to evaluate the quality status in a timely manner. Moreover, quality activity rules and annual quality objectives are distributed group-wide in an attempt to develop and enhance quality activities.

Acquisition of ISO 9001 or IATF 16949 Certification

QuiC Activities to Improve Quality with Full Employee Participation

Since 2003, the NGK Group has held QuiC (Quality up innovation Challenge) quality improvement activities in which all employees participate. These activities consist of quality improvement activities by small groups or individuals and suggestions that strive to enhance the quality of production; best practices are then shared by the entire NGK Group. Every July, NGK holds a company-wide contest at its headquarters to highlight examples of outstanding improvement activities with the intent of horizontal expansion throughout the company.

In July of FY2022, we held the Company-wide QuiC Activities Contest. Due to the COVID-19 pandemic, we held both physical and online versions concurrently. In October we held the NGK-BOX/Surprising Challenges! best practices presentation. NGK-BOX/Surprising Challenges! provides a company-wide forum for laterally sharing reform examples and model initiatives in order to boost employee motivation and invigorate the workplace. This was our third time to hold the event.

In FY2023, two events will be held; one is a company-wide contest focused on sharing manufacturing department best practices in July, and another is an NGK-BOX/Surprising Challenges! event to share innovations and best practices implemented within the NGK Group in October.

Suggestion Activity Participation Rate

| FY2020 | FY2021 | FY2022 | |

|---|---|---|---|

| Manufacturing Department | 93% | 82% | 89% |

| Non-manufacturing Department | 83% | 71% | 76% |

| Clerical Department | 50% | 25% | 27% |

| Number of suggestions | Approx. 19,000 | Approx. 16,400 | Approx. 15,600 |

NGK-BOX/Surprising Challenges! best practices presentation held online

Sending Award Recipients and Outstanding Proposal Commendation Recipients to Training in and outside Japan

Training at a Group Companies Outside Japan

Normally, Outstanding Proposal Commendation recipients and Grand Prize recipients visit Group companies outside Japan at the end of October through early November. However, in FY2022, as in FY2021, this overseas visit was canceled due to the COVID-19 pandemic.

We intend to resume these best practice overseas promotion activities once the COVID-19 pandemic has been contained.

Training in Japan

For the first time in three years, we held domestic training that had been cancelled since FY2020 due to the effects of the COVID-19 pandemic. From December 7 through 10, 16 Outstanding Proposal Commendation recipients and QuiC Excellence Award and Special Award recipients visited Okinawa to attend a nationwide QC Circle Conference and participate in discussion sessions about various topics, such as differences between NGK and other companies.

Strengthening Quality-Related Education

The NGK Group aims to provide customers with product quality that exceeds expectations. Hence, we are continually working to improve the quality-related education that is given to all employees in order to ensure they are equipped with quality-related skills and greater quality-related awareness.

We place the greatest emphasis on practical training tied directly to each employee’s job duties and Quality Management System (QMS) training aimed at promoting systemic improvement in operations. So, we conduct long-term individual training which lasts for six months. Due to the continuing COVID-19 pandemic, the following training was able to be provided via online delivery and video streaming, COVID-safe classroom instruction, or some combination thereof.

Quality-Related Education in FY2022

| Training name | Number of participants | Objectives and key characteristics |

|---|---|---|

| Problem Solving Training (young NGK employees) |

Lecture: 67 participants Individual instruction: 32 participants |

|

| SQC (Statistical Quality Control) Methods Training (those interested/including NGK Group) | A total of 356 participants |

|

| Reliability Basics Training (those interested/including NGK Group) | Reliability Basics Training 1: 103 participants |

|

| Reliability Basics Training 2: 80 participants |

|

|

| Study of Failure and Methodology of Creation (those interested/including NGK Group) | Lecture for directors and general managers: Approx. 150 participants Lecture for practitioners: Approx. 200 participants Guidance and consultation: 20 participants |

|

| QMS Training (those interested/including NGK Group) | ISO/IATF standards interpretation: 594 participants |

|

| ISO/IATF Internal Quality Auditor training: 129 participants |

|

|

| VDA 6.3 Process Auditing Seminar: 41 participants |

|

Raising the Level of Maintenance Activities

With the aim of achieving a higher standard for maintenance activities and of improving productivity, a number of NGK Group employees in FY2022 took on the challenge of the Self-Maintenance Expert Test (Japan Institute of Plant Maintenance). This qualification is given to those who possess a broad range of necessary knowledge and skills concerning quality management, safety, and machinery maintenance, and are recognized as having the ability to plan and implement voluntary maintenance activities and provide instruction.

The NGK Group will continue encouraging employees to take the Self-Maintenance Expert Test as well as cultivate voluntary maintenance activities and stimulate greater employee motivation.

Number of Employees Who Passed

| Company name | No. of Level 1 examinees | No. of employees who passed Level 1 (pass rate) | No. of Level 2 examinees | No. of employees who passed Level 2 (pass rate) |

|---|---|---|---|---|

| NGK | 33 | 11 (33%) | 34 | 24 (71%) |

| NGK Ceramic Device | 5 | 4 (80%) | 55 | 36 (65%) |

| NGK Electronics Devices | 7 | 1 (14%) | - | - |