Ceramics leader drives a carbon-neutral and digitalised future

This content was paid for by NGK Insulators and produced in partnership with the Financial Times Commercial department.

As the world grows more connected, global shifts are changing how we live and do business. These long-term driving forces, known as megatrends, will significantly impact our collective futures.

In 2017, Sweden became the first country to pledge to a net-zero target by 2045. Now more than half the countries in the world, along with an ever-growing number of companies, have pledged to carbon neutrality, an ambition which covers over 90 per cent of the current global economy.

Achieving this target by 2050 requires drastic reductions in greenhouse gas emissions. To keep on track, all passenger cars sold by 2035 must be electric. Two-thirds of the world’s energy supply must come from renewable sources such as wind, solar, bioenergy, geothermal and hydropower by 2050. And energy-intensive sectors like steel, cement/ceramics, and transport will have to wean off fossil fuels.

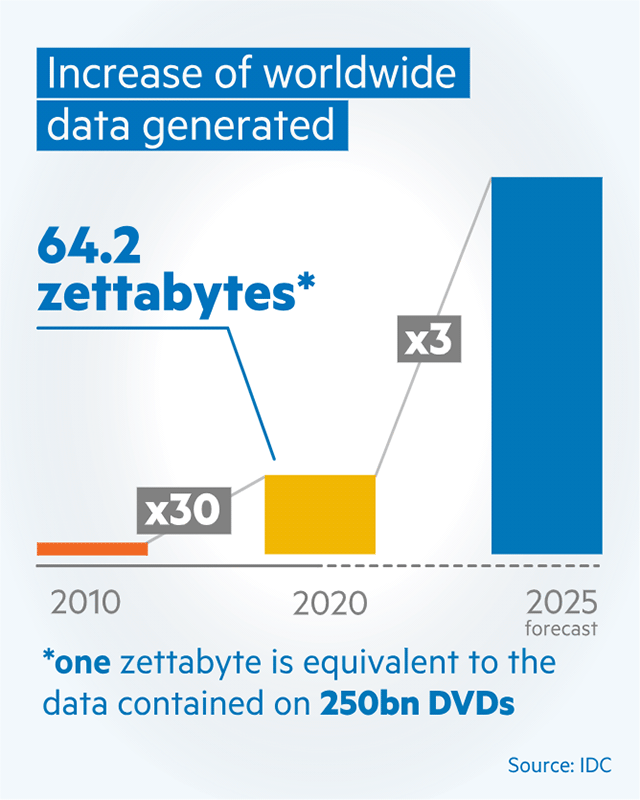

The other trend, digitalisation, has been equally fast and furious. Internet traffic, ecommerce, IoT, AI, and big data use continues to surge. Between 2010 and 2020, the amount of data generated globally has increased over 30 times to 64.2 zettabytes (one zettabyte being approximately data worth 250 billion DVDs). That figure is forecast to nearly triple again by 2025.

Adapting to these kinds of far-reaching changes is no easy task.

But for some they represent opportunities to further evolve core competencies, capture markets, and contribute new social value. NGK Insulators (NGK), the world’s leading ceramics technology company, is one such challenger.

Adapting to and adopting megatrends

On the face of it, an energy-intensive manufacturer which generates a substantial chunk of its sales from products to filter out exhaust from internal combustion engines would seem an unlikely champion for transitioning to a decarbonised and digitalised future. But it surprisingly is.

To start with, NGK is slashing its own emissions at a dramatic pace.

This year, the company switched to using renewable energy in all its European factories, and is aiming to achieve the same for all factories outside Japan by 2025. It aims to achieve carbon neutrality across all operations by 2050.

Simultaneously, the company is pivoting towards producing smart, fossil-fuel-free solutions for other applications.

“The world is currently moving towards a carbon-neutral, digital society. We already possess many products and technologies for these areas,” says Shigeru Kobayashi, NGK’s president. “We will continue to apply our advanced technologies in responding to issues such as energy and the environment to meet the expectations of our global society.”

Such solutions include the grid-scale NAS* battery to contribute to renewable energy storage; subnano-ceramic membranes to capture carbon dioxide at molecular level; and ultra-thin EnerCera* batteries to enable maintenance-free IoT devices. Moreover, the company supplies vital ceramics products used in semiconductor manufacturing, data centres, and mobile phones, among other electronic devices.

Promoting new value

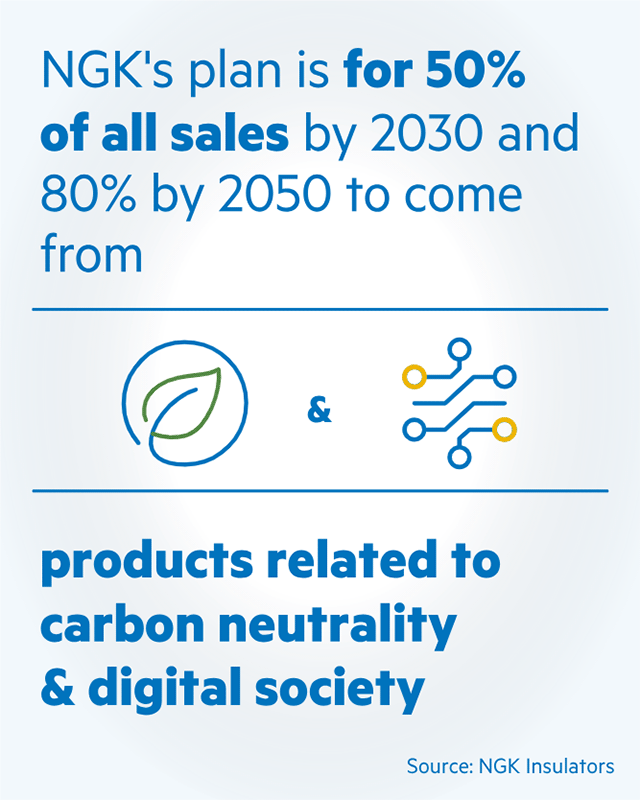

The plan is for half of all NGK’s sales by 2030—and 80 per cent by 2050— to come from products related to carbon neutrality and digital society.

To that end, the company established a new division called Corporate NV (New Value) Creation earlier this year. Some ¥300bn will be poured into R&D over the coming decade, with a mission to generate over ¥100bn in new products (which represent a fifth of current total sales) by 2030.

“Under this division, we hope to bring together the marketing and development of new products across the company and accelerate commercialisation,” says Ryohei Iwasaki, NGK’s executive vice president who heads the new division.

The organisational change is also expected to help secure talent, integrate overseas offices, and overall “inculcate a pioneering spirit”, Iwasaki explains. Through this pivot, the company also hopes to promote greater external collaboration.

“We are moving away from a mindset of doing everything by ourselves. Instead we will further form collaboration with the outside to bring our competitive technologies to market and realise their use in society,” explains Iwasaki.

Over the past year, the company invested in a start-up with ultrathin solar cell film technology and another start-up with unique AI technology.

Ceramic abilities

NGK has a long-standing track record of successfully adapting to change.

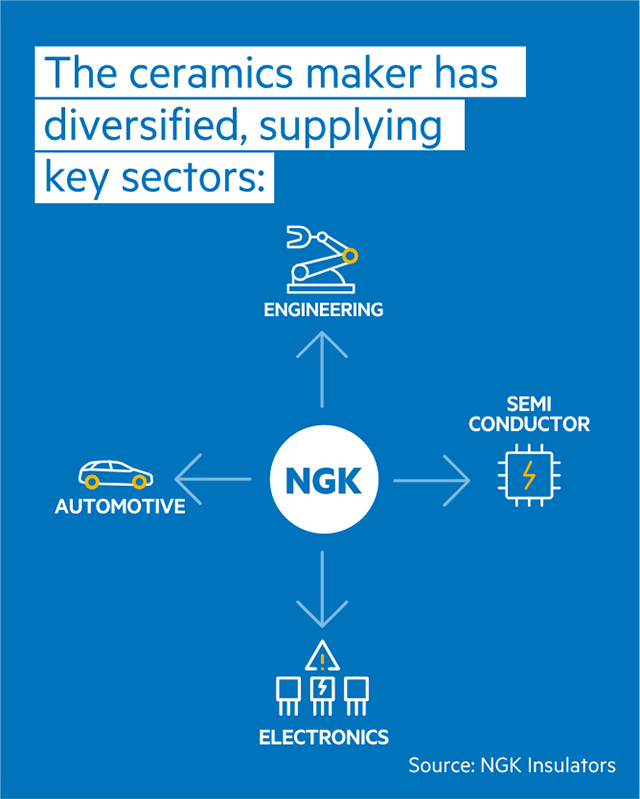

Originally founded to manufacture insulators for Japan’s first electric grid over a century ago, the ceramics maker has diversified into supplying goods for the automotive, engineering, semiconductor, and electronics sectors. This varied mix of business divisions has given the company the time and resources to shift to changing market conditions.

“The key is in our intangible assets. We have been conducting basic research on ceramics for a very long time, accumulating know-how that is not replicable,” says Kobayashi. The expertise has been used to supply high-end ceramics products and materials for leading global companies in key industries, keeping NGK competitive and abreast of industry developments.

“Ceramics is also a materials industry and requires considerable capital investment, creating a high barrier entry for newcomers. So long as we don't slacken investment in this area, we can continue to win, ” says Kobayashi.

Looking to the future, Kobayashi expects the application of machine learning and algorithms, in an approach called Materials Informatics, to its vast datasets on all things ceramics to accelerate further development.

Finally, NGK appears well insulated from rising geopolitical risks. Production of automotive-related products is localised for each of its major markets, while its semiconductor-related production sites are located in Japan and the US. As the global semiconductor manufacturing equipment market is poised to grow further in the mid- to long-term, it expects the reshoring of chip production globally to boost its sales and has recently invested in expanding production at all factories to ensure that they could meet future demands.

Previously considered technically infeasible

NGK says its mid- to long-term vision is to “refine and utilise ceramic technologies to realise things which were previously considered technically infeasible”.

Some notable solutions being rolled out are ceramic membranes that directly capture or filter out carbon from the ambient air and industrial exhaust gas. The company is currently producing unique batteries that enable IoT devices to run indefinitely with little maintenance, and high-performance wafers for high-speed communications.

“Even more is possible,” Iwasaki says. “We have the technical capabilities to continue to create more value”.

NAS and EnerCera are trademarks of NGK Insulators, Ltd., registered in the US and other countries.