Scaling carbon capture with an abundant material

This content was paid for by NGK Insulators and produced in partnership with the Financial Times Commercial department.

For most people, 'ceramics’ conjures up images of kilns and pottery, tableware and tiles, or perhaps super-sharp specialist kitchen knives.

But fewer realise that the ceramic industry keeps the modern economy ticking. For example, ceramics are the most commonly used insulators in electric systems, vital for power transmission and distribution. Vehicles would choke the skies with toxic gases without the ceramic substrates used in modern catalytic converters. And ceramic components are also essential for producing semiconductors, which are the building blocks of modern computing.

This abundant and versatile material, invented more than 25,000 years ago, now has another vital role to play. As the global economy commits to carbon neutrality by mid-century, it’s becoming clear that ceramics could help us decarbonise our future.

Ceramics for CCUS

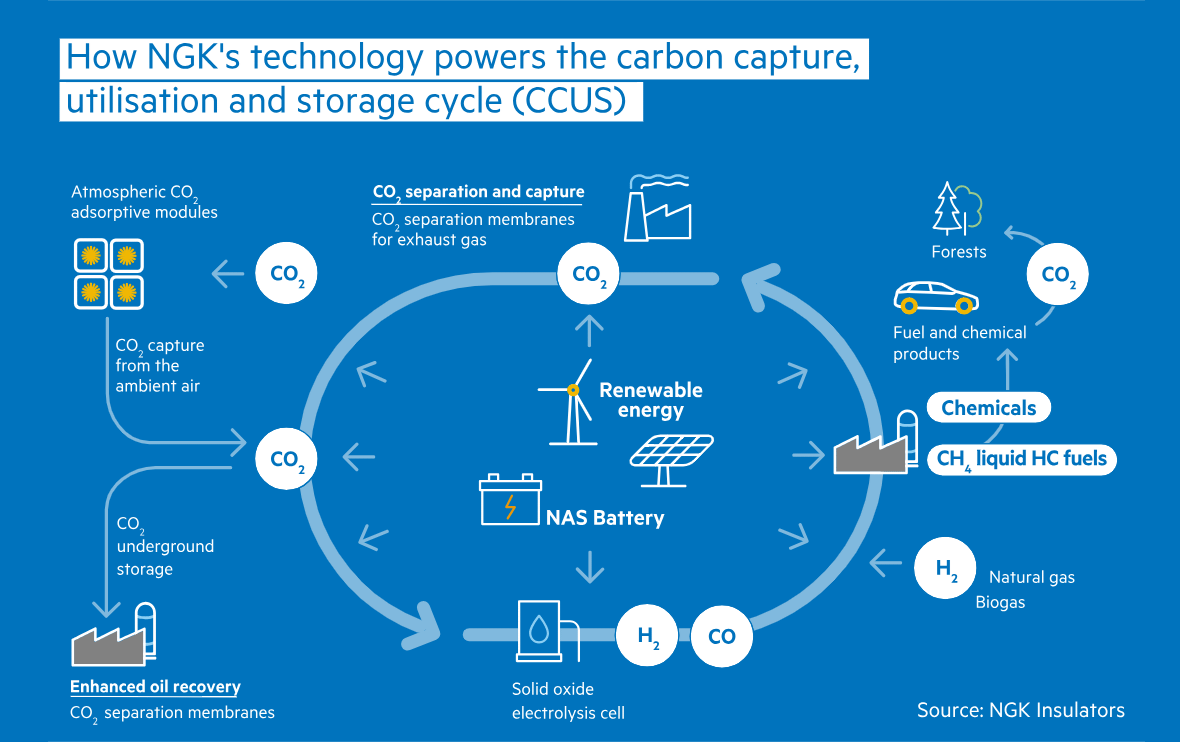

As we cannot realistically transition fully to non-carbon energy sources overnight, various CCUS (carbon capture, use, and storage) technologies to keep GHG emissions from entering and removing them from our atmosphere are urgently needed.

The challenge, however, is to develop viable solutions that can separate carbon dioxide at scale. Ceramic-based filters are one promising option.

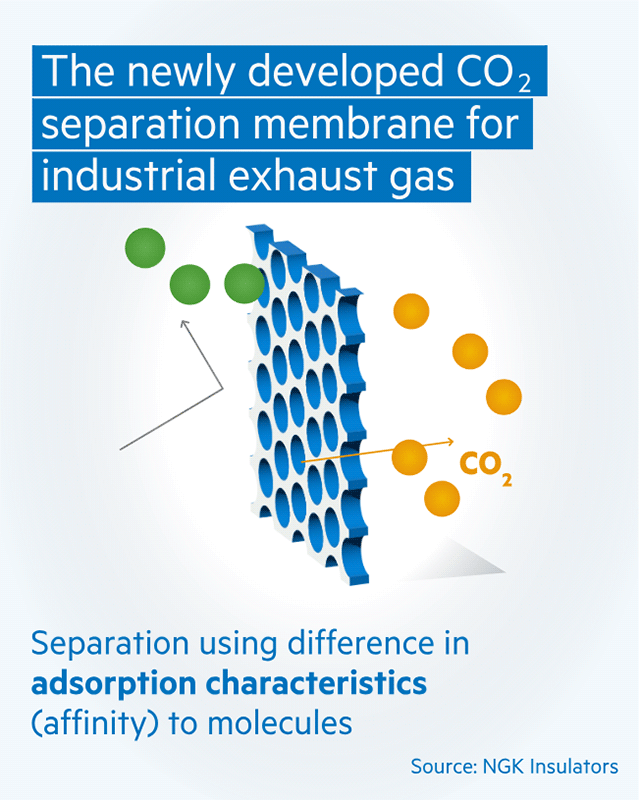

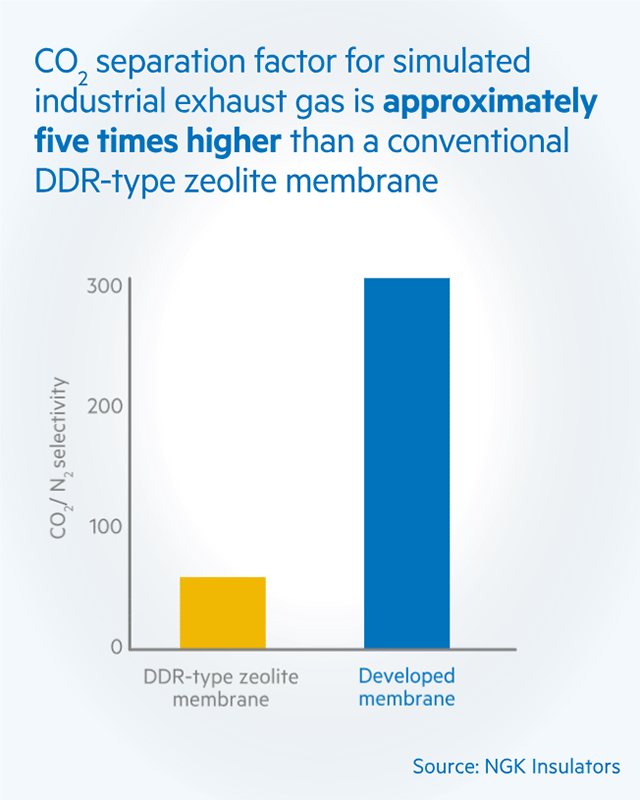

Global industrial ceramics giant NGK had already successfully developed the world's largest ceramic CO2 separation membrane, known as DDR-type zeolite membrane. Last year, the company took the technology further - with the announcement of the successful development of a carbon dioxide separation membrane for industrial exhaust gas.

“Compared to rival polymer membranes, ceramic membranes can achieve high accuracy in separating out molecules under conditions of high temperature and pressure, while being resistant to solvents and corrosion,” says Ryohei Iwasaki, NGK’s executive vice president and head of Corporate NV (New Value) Creation.

In a test simulating industrial exhaust gases, the newly developed membrane achieved a CO2 separation factor for simulated industrial exhaust gas approximately five times that of conventionally developed membranes. The company hopes to commercialise the technology to capture emissions at factories and power plants by 2030.

Equally pressing is the need to capture emissions already released into the air. All signs point to growing momentum for the technology of DAC, or direct air capture of greenhouse gases.

In 2020, governments around the world committed over $4bn to back the development and deployment of DAC technology. The first large-scale plant capable of capturing up to 1m metric tonnes of CO2 (MtCO2) per year will begin operating in the US by the mid-2020s. The International Energy Agency forecasts that DAC must be scaled up from the current 0.01 MtCO2 to 980 MtCO2 by 2050 to reach net-zero emissions by 2050.

NGK hopes to meet this challenge by developing an atmospheric CO2 adsorption module based on its HONEYCERAM* technology for automotive ceramics. Iwasaki sees very high market potential for such a product once demand takes off for DAC. When orders do come in, Iwasaki explains, NGK’s automotive ceramics factories across the globe can be rapidly repurposed to produce these products for DAC.

Stabilise the grid

Another vital technology needed at scale to achieve carbon neutrality are batteries which can store intermittent renewable energies such as wind and solar. Large-scale energy battery capacity will stabilise grids, storing excess energy and releasing it in times of high demand or when renewable energy generation falters.

Forecasts of battery demand are prompting a global upsurge in investments for battery gigafactories. Rising volatility in the electricity market is an incentive to store and sell power to the grid when prices are high and charge up batteries when costs fall. These factors will continue to drive growth for demand of large-scale energy batteries. In its roadmap for the global energy sector, the International Energy Agency expects installed grid-scale battery storage capacity to expand 44-fold between 2021 and 2030 to 680 GW.

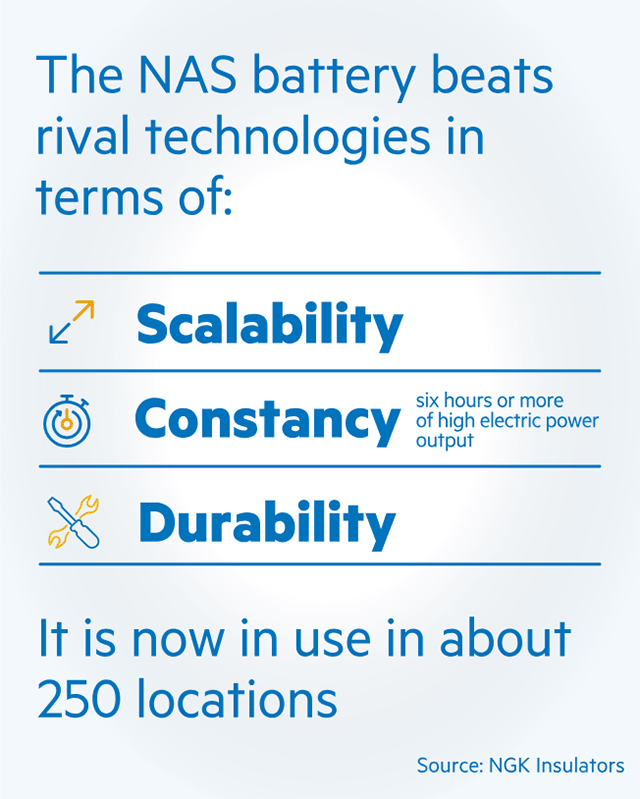

Here, NGK’s ceramic-based (NAS*) battery has strong potential in the market. It effectively meets the requirements of long-duration energy storage systems for renewables in an increasingly volatile electricity market. Used in about 250 locations worldwide, the battery beats rival technologies in terms of scalability, constancy of six hours or more of high electric power output, and durability.

Recent deployments of NAS systems include Taiwan’s Kinmen Island, German energy company BASF’s factories worldwide and various locations within Japan.

The battery is also gaining traction as a backup power source, independent of the grid, to deal with blackouts that have increased in frequency due to natural disasters in recent years.

“We have also started a project with Japanese electronics company Ricoh to create a system that can track the origins of electricity stored in a NAS battery using blockchain,” says Shigeru Kobayashi, NGK’s president. “Such features will make it easier to share and trade electricity for those who need to certify that the electricity is from renewable sources.”

The goal, Kobayashi explains, is to provide “energy as a service” using NAS batteries that can act as banks, or “refrigerators”, customers pay for storage depending on duration and can track their energy easily.

Less carbon, more ceramics

Aside from ceramic-based filters and batteries, NGK has developed numerous other technologies with the potential to contribute to carbon neutrality. These include zinc rechargeable batteries for renewables, which can be used safely indoors without fire risk, and a solid-oxide electrolysis cell that efficiently produces fuels and raw materials from CO2 and water.

NGK has also been deploying its own technologies production processes, such as installing NAS systems in its factories to store renewable energy. These measures mean the company is on target to shift to renewable electricity sources for all factories outside Japan by 2025 and achieve carbon neutrality across all operations by 2050.

Perhaps by then, our impression of the ceramics industry will be less about tiles and knives — and more about how it helped us transition to a carbon-neutral world.

HONEYCERAM and NAS are trademarks of NGK Insulators, Ltd., registered in the US and other countries.