Power semiconductors required for EVs, home appliances, and communications equipment

Semiconductor devices made with gallium nitride (GaN) have been in widespread use mainly for LED lights, and the devices are expected to extend their applications to power electronics including electric vehicles (EVs), home appliances and communications devices. This is because they are resistant to high voltages, high frequencies and high temperatures, which will help in making the products smaller, higher-performance and more energy-efficient.

Sapphire or silicon wafers have conventionally been used as substrates for epitaxy of GaN. To achieve performance suitable for power semiconductor devices, GaN wafers are the perfect choice, since GaN wafers are highly compatible with the crystal structure of the GaN epitaxial layer. The ideal product that makes the most of GaN’s properties is a power semiconductor device with GaN-based function layers grown on a GaN wafer.

Next-generation power semiconductors: GaN thin films on GaN wafers

Power electronics use semiconductor devices designed to convert or control power, thereby reducing power losses for enhanced efficiency of power usage. This technology has been widely applied to home appliances, railways, automobiles, solar power generators and communications devices. Since it is a key technology for energy conservation and CO2 reduction, related markets are expanding around the world and numerous development projects are in progress.

Given these trends, there is strong demand for more advanced power semiconductor devices, GaN-based semiconductor devices in particular are expected to find a wide range of applications, including in home appliances, industrial equipment and EVs. They are also suitable for communications devices that need high-frequency properties and reduced size of equipment.

The ideal product that makes the most of GaN’s properties is a power semiconductor device with GaN-based function layers grown on a GaN wafer.

Striving for mass production of high-quality, large-diameter GaN wafers

Drawing on its experience developing GaN wafers for high-brightness LEDs, NGK applied its own liquid-phase method designed to grow crystals from solution, thereby successfully developing a GaN wafer with hardly any crystal defects. The key to the successful application of GaN wafers is technology for mass production of high-quality and large-diameter wafers. We are moving forward while addressing issues in order to establish technology for the mass production of high-quality, large-diameter GaN wafers for next-generation power semiconductor devices.

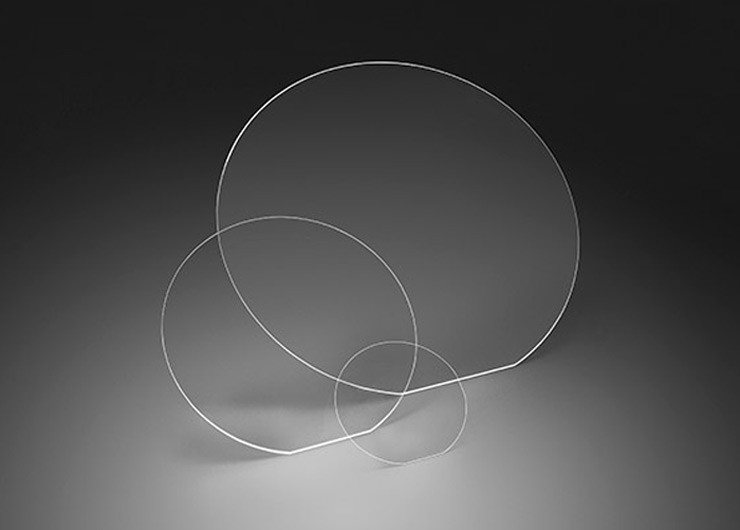

GaN wafer

Writer

Furukori Etsuko

Science and Technology Journalist

Furukori Etsuko graduated from the University of Tokyo with a bachelor's degree in chemistry and liberal arts. While working for a pharmaceutical company, she began writing articles for science magazines and discovered the joy of interviewing researchers and engineers. Since then, she has been writing, researching, planning and editing articles on science, technology and related topics. She is an MIT Science Journalism Fellow and a founding member of Sci-Tech Communications.