Efficient drying at low temperatures even with aqueous solvents

Demand is expanding for various types of films for use in electronic components, display panels, packaging and pharmaceuticals. One of the most prominent growth areas is films for electrodes in lithium-ion batteries, which are seeing a surge in demand with the spread of electric vehicles.

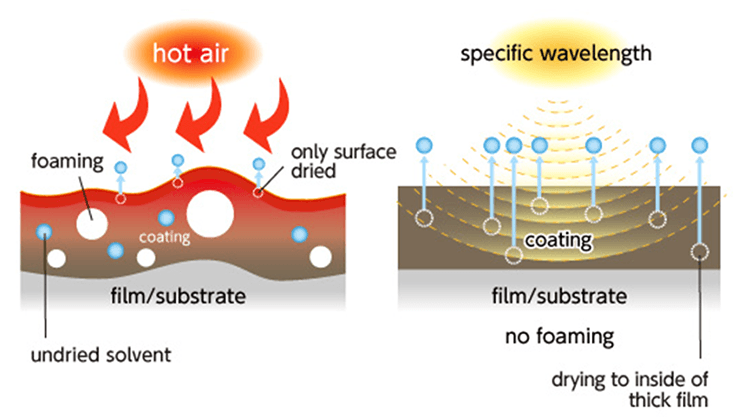

An important part of the film manufacturing and processing is drying to evaporate the solvents. Due to concerns about the environment, we need to switch from organic to aqueous solvents. However, with aqueous solvents, hot air drying requires a longer processing time, and the use of high-temperature heaters tends to cause degradation of the substrate and the coating.

This is why the light drying method was invented. Near-infrared rays, which are easily absorbed by water molecules, dry an object by selectively irradiating it to break the hydrogen bonds between water molecules. This is a revolutionary method that allows efficient drying at lower temperatures and brings us a step closer to eliminating organic solvents entirely.

Utilizing the various heat treatment technologies that NGK has refined

NGK has cultivated a variety of heat treatment technologies through long experience manufacturing ceramics. In the process, we have refined our drying technology to safely and efficiently evaporate only the target solvent. Solvent drying is a little-known but crucial process that greatly affects the quality of a product.

Drying is becoming an increasingly diverse field, including low-temperature drying that does not damage heat-sensitive substrates such as resin film, even drying of thick coating films, and dehydration from inside the substrate. The near-infrared wavelength-controlled drying system developed by NGK can meet all of these needs.

Customization depending on base material, solvent, and coating film

NGK's proprietary wavelength-controlled heater is equipped with a cooling mechanism that allows air to flow near the heater. This prevents the heater itself from getting too hot, blocks the far-infrared rays produced by the heater, and selectively irradiates the object with near-infrared rays. Using wavelengths near 3μm, which are easily absorbed by water, this system can dry efficiently even at relatively low temperatures below 50℃ and is most effective for aqueous solvents.

Efficient drying even at low temperatures

There is little deterioration of the substrate due to heat and no risk that the solvent will ignite. The system can be customized to meet the requirements of the solvent, substrate type and coating thickness.

Recently, a more compact slalom-type system has been developed, which has revolutionized the manufacturing process by enabling even and deformation-free drying in a short processing time. It is expected to play an active role in dehydration processes such as the “absolute drying” of base materials for electrodes in lithium-ion batteries, for which demand is rapidly increasing.

Near-infrared wavelength-control drying system

Writer

Furukori Etsuko

Science and Technology Journalist

Furukori Etsuko graduated from the University of Tokyo with a bachelor's degree in chemistry and liberal arts. While working for a pharmaceutical company, she began writing articles for science magazines and discovered the joy of interviewing researchers and engineers. Since then, she has been writing, researching, planning and editing articles on science, technology and related topics. She is an MIT Science Journalism Fellow and a founding member of Sci-Tech Communications.