Widespread use of UV-LEDs to replace mercury lamps

Countries around the world are working to make their societies mercury-free in order to prevent environmental destruction and health damage caused by mercury. In August 2017, the Minamata Convention on Mercury came into effect to regulate the manufacturing of products that use mercury, in addition to the mining, storage, recycling, and export and import of the chemical element.

This movement has served as the driving force for the development of numerous alternative products. Mercury lamps for ultraviolet (UV) irradiation used to cure resins are already being replaced by LEDs, and LEDs designed to provide shorter-wavelength ultraviolet light for sterilization have also become available. UV-LEDs are, naturally, mercury-free. In addition, given that UV-LEDs consume only a limited amount of power, have a long service life, and are small and lightweight, they are expected to come into widespread use.

UV sterilization technology using LEDs advances and spreads

Sterilization by UV irradiation is now used in a variety of industries, including food, healthcare and sanitation. UV light at wavelengths from 265 nm to 280 nm is used for sterilization as it damages the nucleic acids of germs and viruses.

UV-LED technology for efficient emission of these wavelengths is advancing, and may herald more applications of UV-LEDs that go beyond the use of traditional mercury lamps for sterilization. UV-LEDs for sterilization will likely find a variety of applications connected to our everyday life, such as water treatment at purification plants that provide safe water for drinking, disinfection at public facilities, air cleaning by air purifiers, water purification by water servers for home use, vacuum cleaning, and pest control.

Quartz glass micro-lens enhances irradiation effect

The irradiation range of UV light needs to be reduced in order to produce greater irradiation effects. This reduction helps not only in sterilization, but also in precise curing of resins, such as patterning of printed-circuit boards. A small lens made of high-purity and highly-transparent quartz glass that easily transmits short-wavelength UV light is suitable for the reduction. Quartz glass has a high melting point, and its production and processing requires unique technologies.

NGK provides various lens shapes

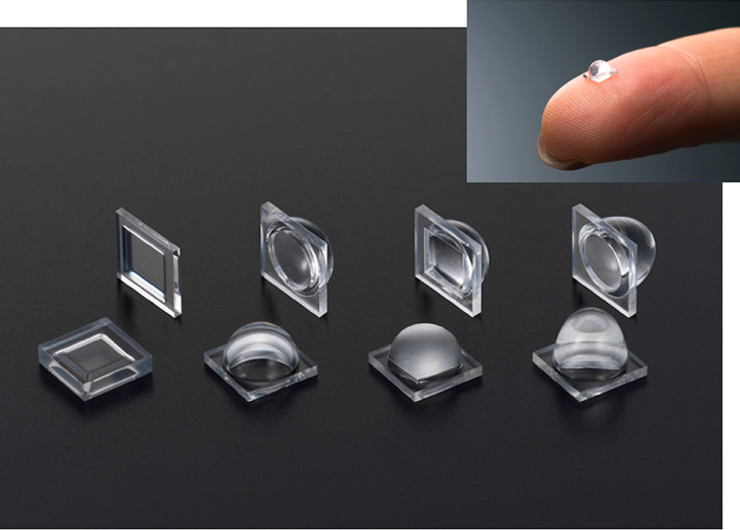

As UV-LEDs find a wider range of applications, lenses for them need to be more varied in size and shape. With the unique process it has developed over the years, NGK has successfully produced quartz glass lenses in complex three-dimensional shapes.

Micro-lens for UV-LED

Writer

Furukori Etsuko

Science and Technology Journalist

Furukori Etsuko graduated from the University of Tokyo with a bachelor's degree in chemistry and liberal arts. While working for a pharmaceutical company, she began writing articles for science magazines and discovered the joy of interviewing researchers and engineers. Since then, she has been writing, researching, planning and editing articles on science, technology and related topics. She is an MIT Science Journalism Fellow and a founding member of Sci-Tech Communications.