Nearline storage becoming mainstream amid changing times

Methods of data storage are changing over time. In the past, storage that was frequently accessed, such as the execution server behind a bank ATM, was referred to as online storage, while that used for archiving was referred to as offline storage.

However, with the development of information and communication technology and the spread of social networking and video distribution services, large amounts of data such as video and audio are now frequently exchanged over the Internet, and many database servers have been established to store such data. This third type of storage is known as nearline storage.

Nearline storage HDDs require high capacity and reliability

Hard disk drives (HDDs) are the most common data storage devices for nearline storage. As the amount of data to be handled increases, HDDs are required to have higher capacity, and development is vigorously underway to achieve both higher capacity and higher reliability.

Currently, most HDDs for nearline storage have nine disks and write on both sides of each disk. However, there is a limit to the number of disks that can be used to increase capacity, so efforts are being made to narrow the track spacing, which is now several tens of nanometers. Technology to write information in finer detail using heat and microwaves is also being developed.

A micro actuator that enables precise positioning of the magnetic head

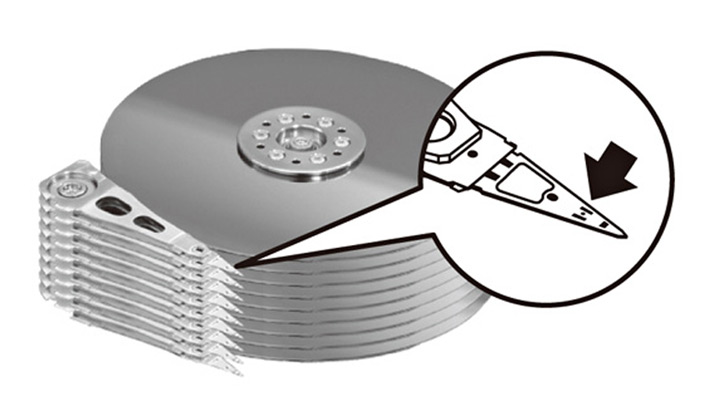

For this reason, the positioning of the magnetic head, which reads and writes information on the disk, also needs to be made more precise, and a micro dual-stage actuator (DSA) suspension is now used.

The magnetic head of the HDD is mounted on an arm and is driven by a coil at the base of the arm. The DSA adds a micro actuator on the arm near the magnetic head, which allows for finer adjustment of the magnetic head position.

Micro actuator for precise magnetic head positioning

NGK's piezoelectric element is small but deforms greatly with low voltage

The micro actuator contains a piezoelectric element that deforms when voltage is applied. NGK's piezoelectric element is about the size of a quarter of a grain of rice. The ceramic material and the structure of the element were developed by NGK’s original technology, and even though the element is extremely small, it deforms greatly with low voltage, enabling precise positioning of the magnetic head.

NGK has developed technology for efficiently molding, processing and firing tiny piezoelectric elements, as well as the technology for inspecting all finished products. Our products, with their high performance and reliability, are highly evaluated by HDD manufacturers.

Piezoelectric micro actuator

Writer

Aoyama Seiko

Science and Technology Journalist

Aoyama Seiko studied chemistry at Ochanomizu University and its graduate school. She has worked in public relations for a research funding agency and as a journalist and editor for a chemistry magazine. She now works for Sci-Tech Communications, producing public relations materials (newsletters, website text, etc.) for research institutions and technology companies. She also teaches science writing at several universities.