Continuous Drying Furnaces for Lithium-Ion Battery Electrode Substrate Dehydration (Absolute Drying) Processes

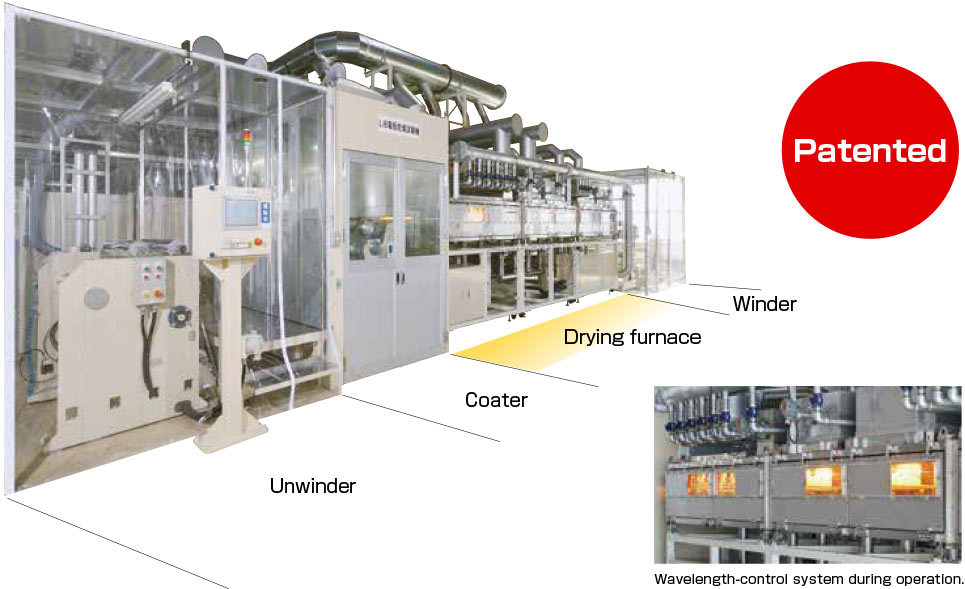

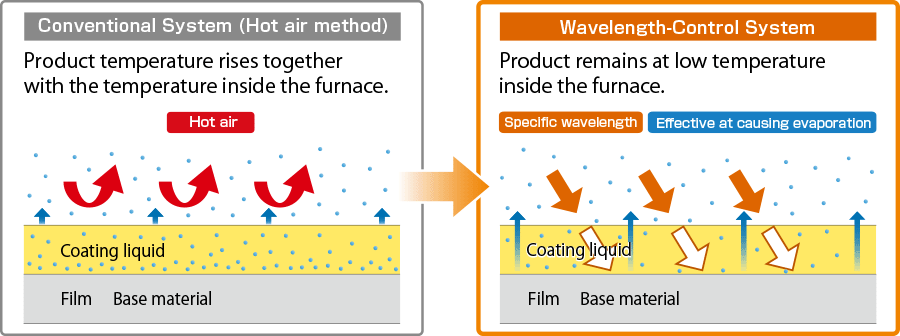

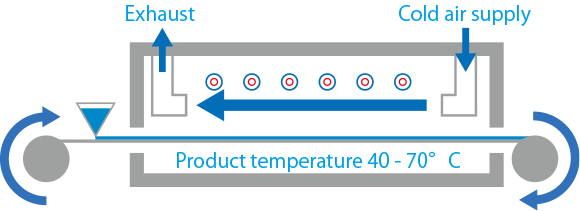

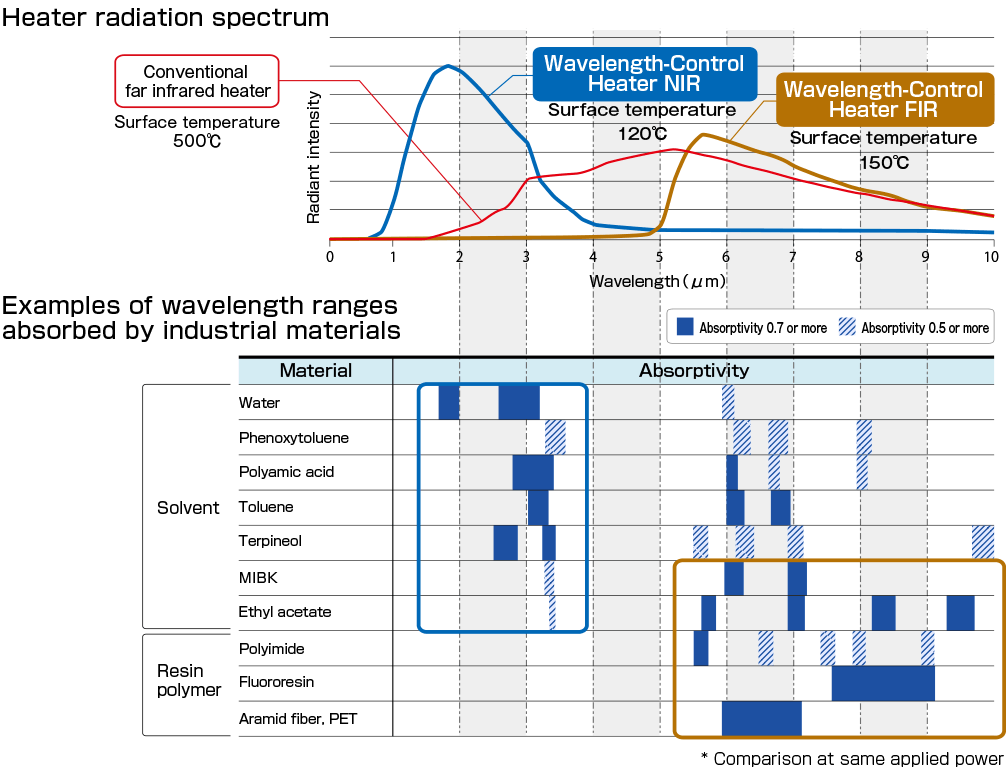

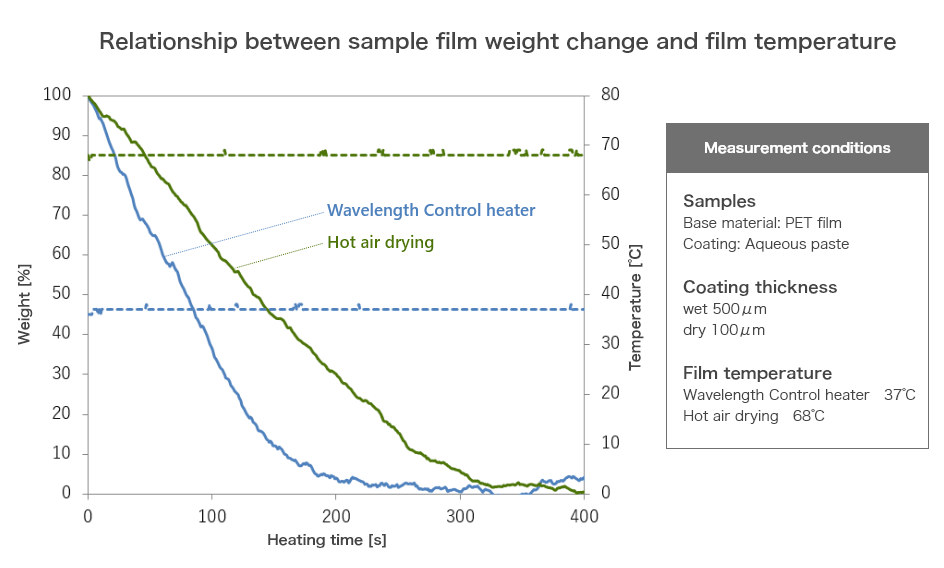

NGK combined its proprietary wavelength-control heater with a slalom configured roll-to-roll furnace that allows continuous conveying, transforming the conventional batch process for lithium-ion battery electrode substrate dehydration into a continuous process.