Negative emission technologies become increasingly essential

Many countries around the world have set a goal to achieve carbon neutrality by 2050 to address climate change. They are advancing the transition from fossil fuels to renewable energy sources and the introduction of CO2 emission reduction technologies. However, there are limits to emission reductions, and CO2 that has already been emitted continues to accumulate in the atmosphere. Therefore, what will become indispensable in the future is “negative emission technology,” which involves artificially capturing and fixing CO2 from the atmosphere.

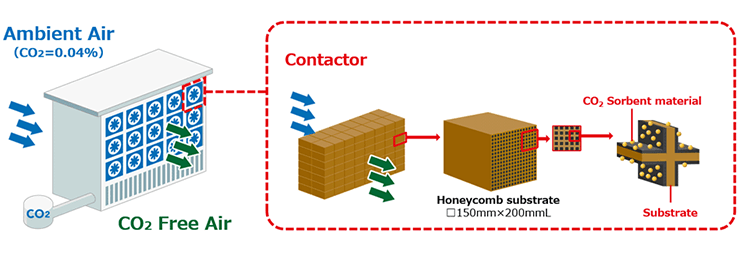

One negative emission technology being considered is increasing forests to absorb CO2, but this method requires a vast area. In contrast, DAC aims to capture CO2 from the atmosphere using an engineering process. Since the concentration of CO2 in the atmosphere is only 0.04%, innovative technology is required to achieve DAC. NGK is leveraging its established ceramic technology and working on development to contribute to the early practical application of DAC.

Repurposing automotive emission control ceramics

HONEYCERAM

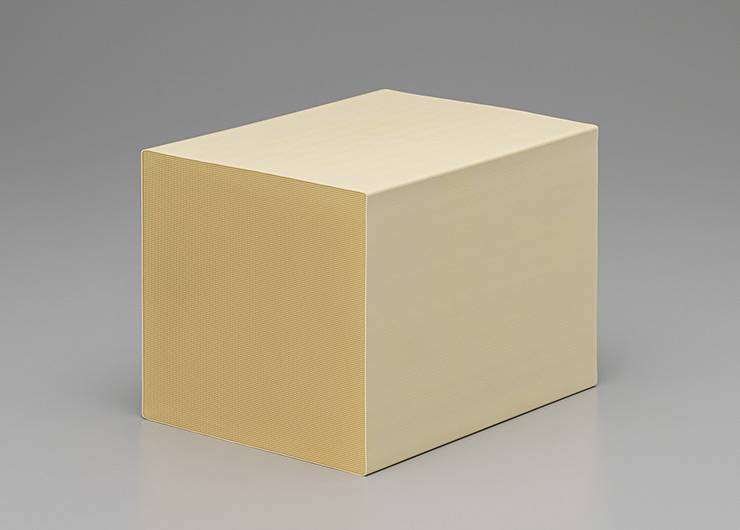

For DAC, solid adsorption methods are primarily used to capture CO2. This involves attaching a sorbent material, such as an amine known for CO2 capture, to a solid substrate, and then passing ambient air over it with a fan to adsorb the CO2. NGK aims to repurpose its HONEYCERAM ceramics, which have a proven track record in automotive emission control, as the substrate for solid adsorption methods in DAC. HONEYCERAM features a honeycomb structure with square openings aligned in a lattice pattern, and a catalyst for emission control is supported inside these openings. This technology has been adopted by many automobile manufacturers.

Removal of CO2 using DAC

Why is NGK considering repurposing HONEYCERAM for DAC? Because honeycomb-type substrates have several key advantages over pellet-type substrates, which are already being commercialized for DAC. First, the honeycomb structure has a larger surface area compared to pellets, allowing for more efficient CO2 capture in smaller equipment. Additionally, since the holes in the honeycomb are continuous, there is lower resistance when air is blown through with a fan, which helps to reduce operational costs.

Furthermore, HONEYCERAM has the advantage of having thin, lightweight walls, which means it has a small thermal capacity. In solid adsorption methods, the captured CO2 is released through heating process. A lower thermal capacity translates to energy savings during the heating process, making HONEYCERAM an efficient choice for DAC applications.

Deploying DAC with renewable energy around the world

To develop a substrate for DAC based on HONEYCERAM, various factors need to be optimized, including the size of the honeycomb holes, wall thickness, and the method of supporting the sorbent material. NGK is working on optimizing these factors through iterative testing and development with users. Although manufacturing honeycomb structures is not simple, NGK has already commercialized HONEYCERAM and established mass production technology. Moreover, with production sites around the world, the company has the advantage of being able to supply locally as demand for DAC increases.

Operating a DAC plant requires electricity, and if this electricity is generated with CO2 emissions, it negates the benefits. Therefore, DAC plants are likely to be constructed near facilities that use renewable energy sources, such as geothermal power plants, which provide both clean electricity and heat for CO2 release. It seems that the day when a honeycomb structure developed from HONEYCERAM will be used in these DAC plants is not far off.

*HONEYCERAM is a trademark of NGK INSULATORS, LTD., registered in the U.S.

Ceramics for DAC

Writer

Aoyama Seiko

Science and Technology Journalist

Aoyama Seiko studied chemistry at Ochanomizu University and its graduate school. She has worked in public relations for a research funding agency and as a journalist and editor for a chemistry magazine. She now works for Sci-Tech Communications, producing public relations materials (newsletters, website text, etc.) for research institutions and technology companies. She also teaches science writing at several universities.

![On-Board Monitoring [OBM]](img/keyword3.png)