Creating new products

Ceramic substrates for Direct Air Capture (DAC) systems to Capture CO2 from the Atmosphere

What is Carbon Neutrality?

Carbon neutrality refers to the state in which a net zero balance is achieved between greenhouse gas emissions and absorption. The term net zero means the difference between the amount of greenhouse gas emissions, including carbon dioxide (CO2), and the amount absorbed by afforestation, Direct Air Capture (DAC), and other artificial means, is effectively zero.

What is Direct Air Capture (DAC)?

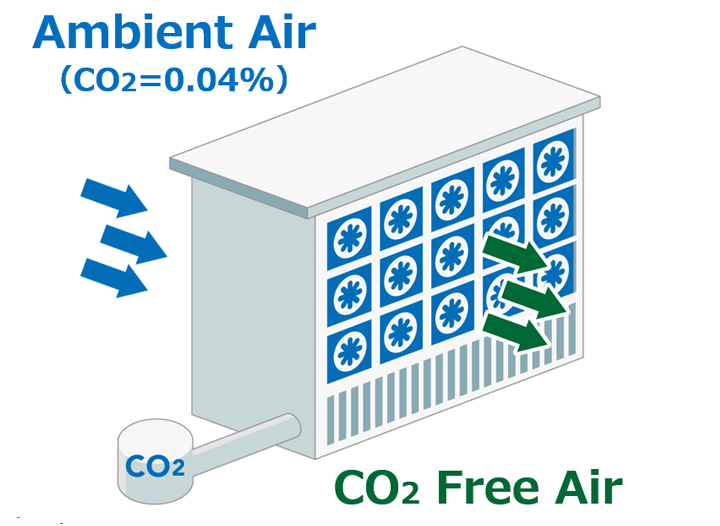

Direct Air Capture (DAC) is a technology for capturing CO2 contained in the atmosphere via direct adsorption or absorption. Projections suggest DAC will absorb approximately 1 billion tons* of CO2 from the atmosphere by the year 2050. DAC has entered the spotlight as a technology with the potential to help achieve carbon neutrality.

Since the concentration of atmospheric CO2 is approximately 0.04%—extremely low—large volumes of air must be treated efficiently to adsorb or absorb significant amounts of carbon.

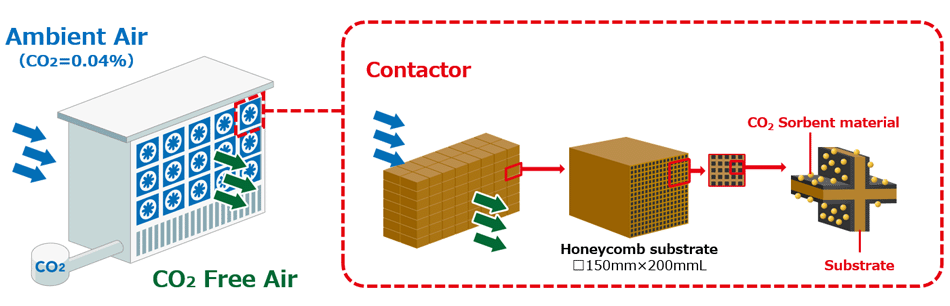

A honeycomb structure sorbent material for DAC currently being developed by NGK offers compact dimensions, large surface area, and low pressure loss (ability to efficiently treat large volumes of air) by applying the ceramic honeycomb structure technology cultivated through the development of ceramic substrates for automotive catalytic converters.

Source: IEA Report

Development of a Honeycomb Structure Sorbent Material for DAC

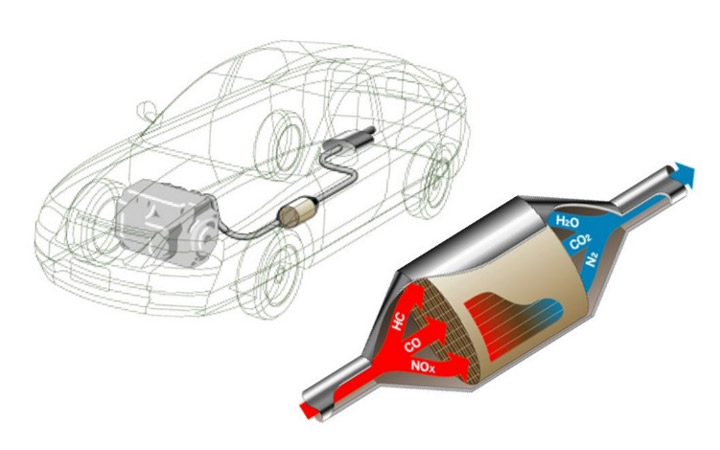

Application of honeycomb structure ceramics has been proven as a reliable and effective technology in automotive exhaust gas purification.

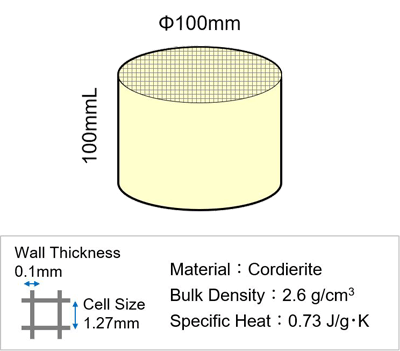

The performance requirements for sorbent material (substrate) for DAC include large reaction area per volume, low pressure losses, and low base material heat capacity.

Many of these performance requirements are the same as those for ceramic substrates for automotive catalytic converters. Honeycomb structure ceramics, which have proven reliable for automotive exhaust gas purification, are regarded as an optimal base material for DAC sorbent materials.

Honeycomb structure ceramics can be produced using the manufacturing and prototype production facilities currently used to manufacture ceramic substrates for automotive catalytic converters. We encourage you to contact us if you need to prototype fabricated.

Performance requirements for DAC sorbent material (substrate) and the solutions

| Purpose | Key Performance Criteria | Solutions |

|---|---|---|

| Efficient chemical reaction between CO2 absorbing layer and CO2 in ambient air | Large reaction area per volume | The honeycomb structure provides a large reaction area within a small volume, contributing to improved CO2 adsorption performance. |

| High air flow rate with small electric energy consumption (improved energy efficiency) |

Low pressure loss | The thin walls of the honeycomb structure realize a low pressure drop, reducing the energy required by air feeding fans. |

| Efficient heating of the substrate adsorbing the CO2 to its desorption temperature (improved energy efficiency) |

Low thermal capacity of substrate | The honeycomb structure and the thin walls enable compact and lightweight designs, reducing thermal capacity and reducing energy consumption during the desorption (heating) process. |

| Resistance to degradation even after repeated heating cycles | High thermal resistance | Cordierite, a type of ceramic, is used. Excellent thermal shock resistance can be achieved by precisely controlling the raw material composition. |

Schematic image of Direct Air Capture (DAC) and honeycomb structure sorbent material

What are ceramic substrates for automotive catalytic converters?

HONEYCERAM, one of the ceramic substrates for automotive catalytic converters, is used as the substrate to hold the catalyst in place in the purification unit. The catalytic device with built-in HONEYCERAM is installed midway in the exhaust pipe connecting the engine to the silencer (muffler) to remove harmful pollutants (HC, CO, NOx) contained in the exhaust gas. HONEYCERAM enables efficient exhaust gas purification based on the large reaction area per volume, low pressure loss, and low heat capacity of the substrate. Since the start of production in the 1970s, 1.8 billion HONEYCERAM units have been manufactured (as of 2021), which continue to purify the exhaust gas of automobiles all over the world.

Comparison of performance of DAC sorbent materials (honeycomb structure and pellets)

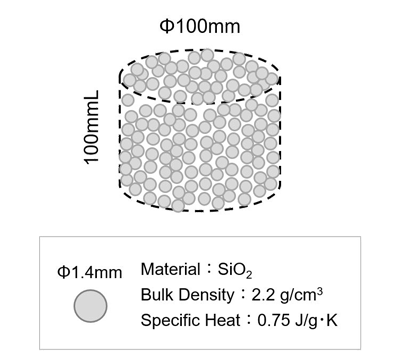

The following table compares the performance of honeycomb structures and pellets as sorbent materials for DAC based on both volume and surface area conditions. Compared to pellets, the honeycomb structure exhibits a lower pressure drop and lower heat capacity, making it ideal for reducing the energy consumed by air feeding fans and reducing the thermal energy required for CO2 desorption.

| Pellets | Honeycomb structure | |

|---|---|---|

| Preconditions |  |

|

| Pressure loss | 1 | 0.02 (1/50 of pellets) |

| Heat capacity | 1 | 0.33 (1/3 of pellets) |

Information in media releases

-

NGK’s honeycomb structures and DAC / Carbon Capture Journal (May – June 2023)

-

Scaling up direct air capture for a net zero future / FINANCIAL TIMES

Prototypes

NGK offers prototypes of honeycomb structure sorbent materials for DAC to companies developing DAC systems. To order a prototype, use the inquiry form provided below.

Inquiry about Research & Developments

Please apply with the contact form and give us your comments or questions.