CO2-EOR technology for recovering crude oil by injecting CO2 into the petroleum reservoir

A new method to treat CO2 as a resource and reuse it is attracting attention. CO2 Enhanced Oil Recovery (CO2-EOR) technology involves injecting CO2 into a petroleum reservoir to produce crude oil. In the process, part of the CO2 dissolves in the crude oil, lowering the viscosity of the oil and increasing its fluidity, which increases the crude oil recovery rate.

The injected CO2 is returned to the ground. It is important to reuse this CO2 to improve the economic efficiency of CO2-EOR, but since gases such as methane that were in the ground are also mixed in, only CO2 must be separated. This is because the higher the CO2 concentration, the better the solubility in crude oil and the higher the crude oil recovery rate.

Separating CO2 with NGK's high-performance sub-nano ceramic membrane that works as a molecular sieve

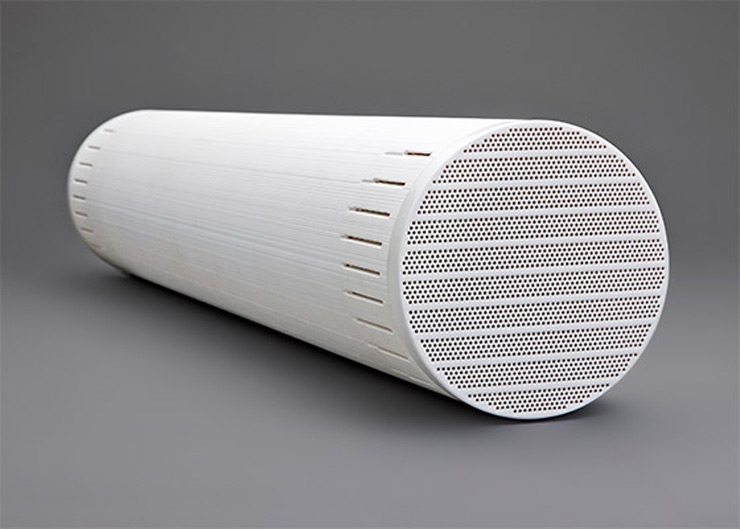

The solution is a high-performance sub-nano ceramic membrane being developed by NGK. The support is a porous ceramic made of alumina. The support is cylindrical, with many penetrating holes like a lotus root, and the inside of the holes is covered with a thin layer of zeolite. The zeolite layer has countless microscopic pores smaller than 1 nanometer, and acts as a molecular sieve to efficiently separate CO2 from the gases derived from crude oil.

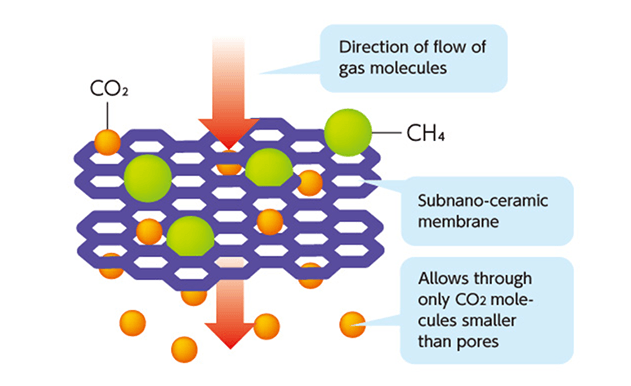

Molecular sieve for efficient separation of CO2 and gas

Of the gases contained in a petroleum reservoir, methane has the smallest molecules, with a size difference of only 0.05 nanometer from those of CO2. For this reason, among the various types of zeolites available, the one with pores suitable for sieving the two gases is used for the membrane. Just by feeding the gas that returns to the ground with crude oil (crude oil-associated gas) through the lotus-like pores, CO2 can be accurately and efficiently separated from methane and other substances. Another advantage of ceramic membranes is that they can provide excellent separation performance even when high-pressure, high-concentration CO2 is passed through them.

CO2-EOR contributes to higher crude oil recovery rate and carbon neutrality

CO2-EOR is also attracting attention as a technology for trapping CO2 in the ground. This is because some of the injected CO2 that does not return to the ground is stored underground. If the CO2 emitted from factories and other facilities is used for CO2-EOR, the CO2 that would have been released into the atmosphere will be trapped underground.

CO2-EOR is a technology that kills two birds with one stone – it can increase the recovery rate of crude oil and at the same time contribute to carbon neutrality. NGK’s high-performance sub-nano ceramic membrane, which we developed by utilizing our accumulated ceramics forming and processing technologies, is expected to play a role in this technology.

High-performance sub-nano ceramic membrane

Writer

Aoyama Seiko

Science and Technology Journalist

Aoyama Seiko studied chemistry at Ochanomizu University and its graduate school. She has worked in public relations for a research funding agency and as a journalist and editor for a chemistry magazine. She now works for Sci-Tech Communications, producing public relations materials (newsletters, website text, etc.) for research institutions and technology companies. She also teaches science writing at several universities.

![On-Board Monitoring [OBM]](img/keyword3.png)