Automotive emission regulations are becoming stricter around the world

With the rise of global environmental awareness, automotive emission regulations are becoming more and more strict. In the EU in particular, nitrogen oxide (NOx) and particulate matter (PM) emissions from diesel passenger cars have been strictly regulated, but from now on, the same standards are expected to be applied to all motorized vehicles, regardless of whether they are diesel or gasoline powered, passenger cars or heavy vehicles. Furthermore, the regulation values for NOx and PM will be made more stringent, and other substances will be added to the list of strictly controlled emissions.

Introducing OBM to monitor each unit

In addition, plans are underway to introduce on-board monitoring (OBM) to increase the effectiveness of the regulations. Currently, before a new vehicle is introduced to the market, it is common practice to check the amount of regulated substances emitted during test runs with test vehicles. OBM uses on-board sensors to constantly monitor the actual emissions of each vehicle driven by ordinary users on the road. By storing OBM data over the life cycle of each vehicle, it is possible to evaluate the total emissions.

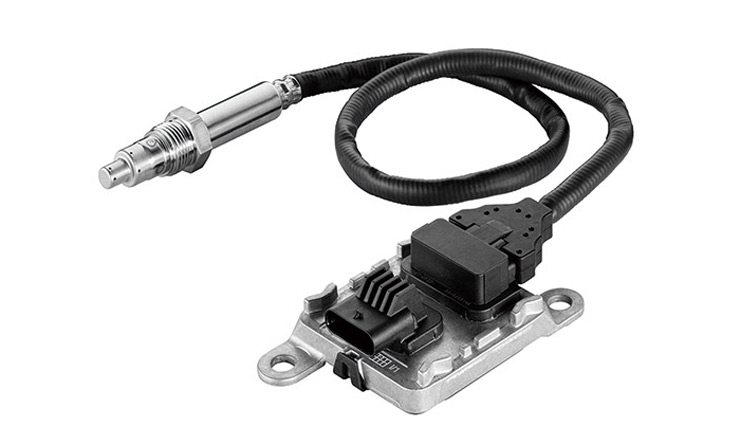

NGK's NOx sensor measures NOx concentration in exhaust gases in real time

The tightening of emission regulations and the introduction of OBM are expected to spread not only in the EU but also around the world. NGK's NOx sensor is the world's first product that can measure NOx concentration in exhaust gas in real time with high accuracy at the ppm level, and has already been adopted by automakers around the world, mainly for diesel vehicles. It is expected to become one of the key technologies to address tighter regulations in the future.

The heart of the sensor is a ceramic element called zirconia, which electrically measures the concentration of oxygen ions (O2-) generated when NOx is decomposed. Using NGK's proprietary technology, a chamber for pre-treatment and decomposition of NOx, and multiple electrodes for measurement, etc. are built into a small element about 1mm thick and a few millimeters wide.

Cross-sectional view of element

![[Cavity 1]1.Removal of oxygen 2.Combustion of combustible gas 3.Conversion of NO2 to NO [Cavity 2]4.NO decomposed with a reduction catalyst and amount of oxygen generated during decomposition measured](img/kw3_item_img2.png)

This sensor is currently being used to reduce NOx emissions from diesel vehicles, whose exhaust pipes are equipped with a multi-stage exhaust gas purification system to remove PM and NOx. In order for these devices to be effective, it is necessary to measure the NOx concentration at each stage of the purification process and precisely control the system.

NGK contributes to environmental conservation with NOx sensors compatible with OBM

Since the zirconia element is heat resistant, it can be inserted directly into the hot exhaust gas, and the sensor shows good response. As exhaust gas regulations become more stringent, exhaust gas purifiers will become more complex, and the number of NOx sensors required is expected to increase. Of course, this sensor will also be powerful for OBM.

In addition, as demand for NOx sensors increases, new requirements are emerging, such as the need for stable monitoring of exhaust gas over a longer period of time and the need to use these sensors to improve the environmental performance of gasoline vehicles. In response, NGK is working to improve the performance and diversification of its NOx sensors. The company hopes to contribute to environmental protection through stricter exhaust gas regulations by expanding the range of vehicles in which they can be used.

High-precision NOx sensor for automotive use

Writer

Aoyama Seiko

Science and Technology Journalist

Aoyama Seiko studied chemistry at Ochanomizu University and its graduate school. She has worked in public relations for a research funding agency and as a journalist and editor for a chemistry magazine. She now works for Sci-Tech Communications, producing public relations materials (newsletters, website text, etc.) for research institutions and technology companies. She also teaches science writing at several universities.