Products

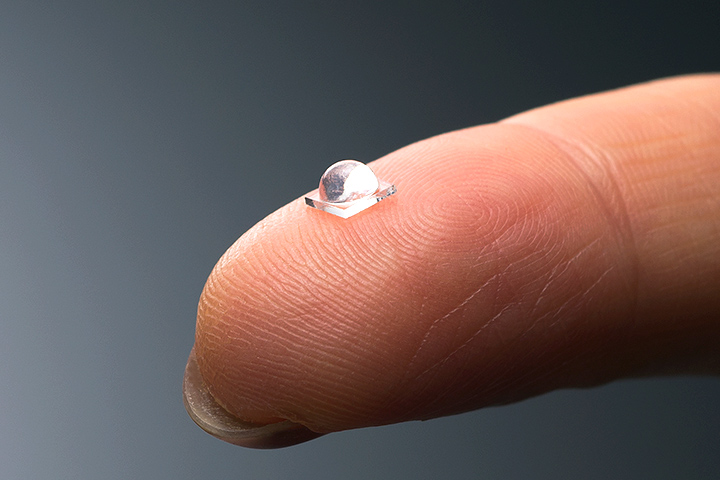

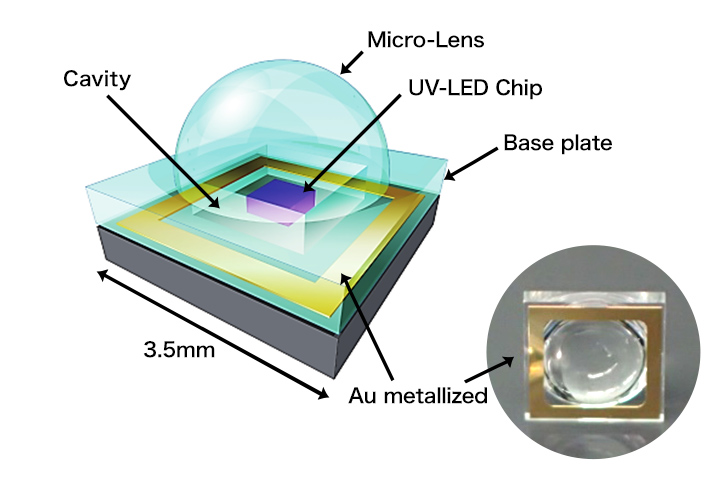

Micro-Lens for UV-LED

Product tags:

Overview

Ultraviolet LEDs (UV-LED) are used in sterilizing and hardening resins. NGK Insulators has developed an extremely small lens with a reduced irradiation range that improves the LEDs' sterilizing effect. These lenses utilize quartz glass with superior transparency and durability, allowing them to produce complex shapes that were formerly difficult to achieve.

Properties

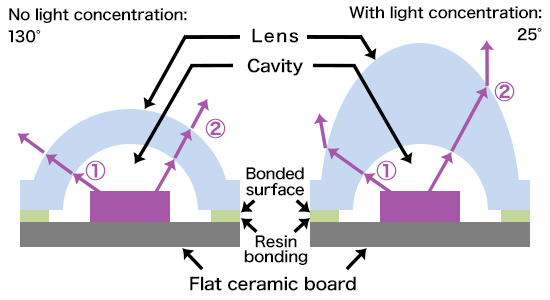

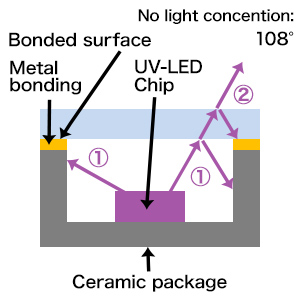

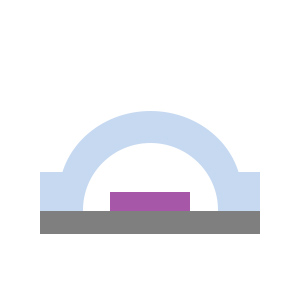

Lens with Cavity.

Lens with a cavity (space) to arrange UV-LED chip.

- Higher light extraction efficiency.

- Reliability of resin bonded products will improve by reducing UV irradiation to lens bonded surface.

- Inexpensive flat ceramics boards can be used.

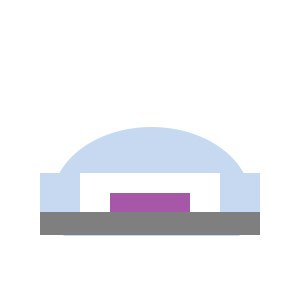

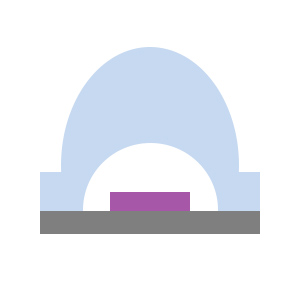

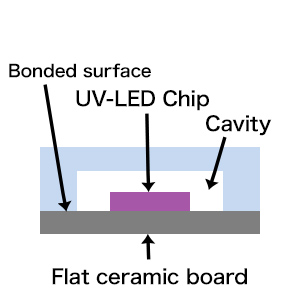

| NGK product (example) | Conventional product |

|

|---|---|---|

| Package image and light angle※ |  |

|

| ①Light extraction efficiency※ |

93% No light absorption in package |

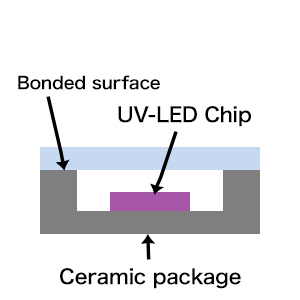

75% UV rays absorbed in side wall of ceramic package |

|

②UV illuminance to bonded surface※

Using conventional products as a base of 100 |

<10 Lower UV irradiation to bonded surface →Enhancing reliability of resin bonding |

100 Heavy UV irradiation to bonded surface →Require expensive metal bonding |

- ※Results of NGK's simulation

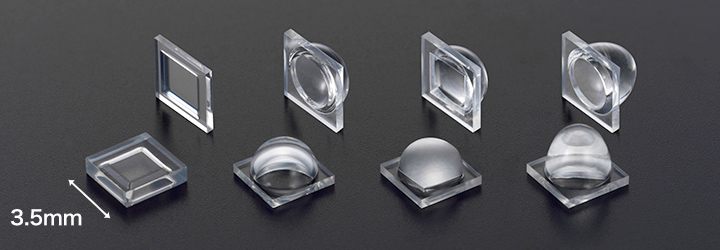

Arbitrary shapes (Lens/Cavity) are available

- Shapes suitable for your UV-LED chips are available.

- Shapes suitable for your applications are available.

- Lenses for multi-chip package (e.g. lens array) are available.

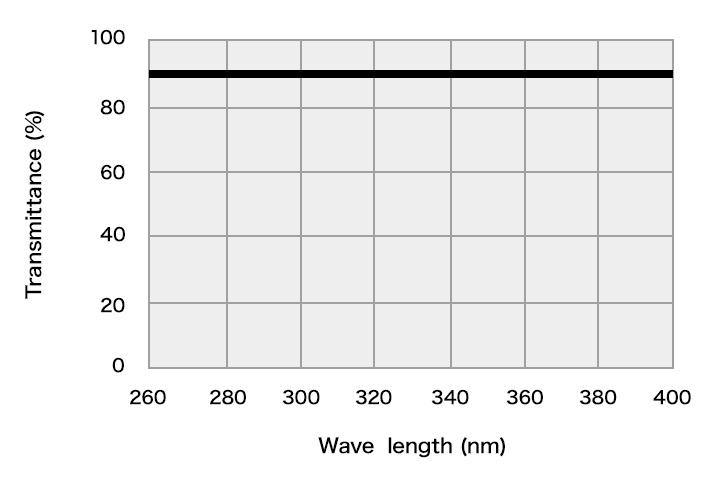

Quartz glass

- High transmittance for UV light (260nm-)

- High durability against UV light (260nm-)

Au metallized

- UV-LEDs with high reliability are available by hermetic sealing using metal with UV resistance.

Optical properties (Simulation)

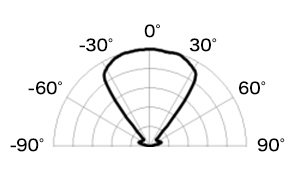

| Feature | Light angle | Light extraction efficiency/Flat board | Conventional product | ||

|---|---|---|---|---|---|

| Lens | Low lens | Tall lens | Hemisphere lens | Flat | Flat |

| Cavity | Square | Dome | Dome | Square | None |

| Image of Package |

|

|

|

|

|

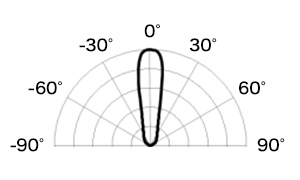

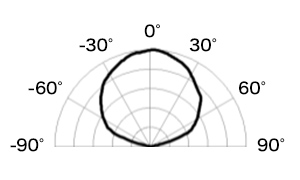

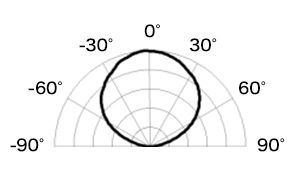

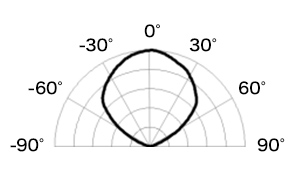

| Light distribution and angle |

|

|

|

|

|

| 77° | 25° | 130° | 122° | 108° | |

| Light extraction efficiency | 93% | 93% | 93% | 91% | 75% |

|

UV illuminance to bonded surface

Using conventional products as a base of 100 |

5 | 9 | 5 | 87 | 100 |

Inquiry about Electronic Components

Please apply with the contact form and give us your comments or questions.