Product

NGK's Ceramics for Purifying Automotive Exhaust Awarded the Ceramics Grand Prize

May 29, 2019

NGK INSULATORS, LTD. (President Taku Oshima; Headquarters: Nagoya, Japan; “NGK”) today announced that it has recently been awarded the 4th (FY2018) Ceramics Grand Prize by the Ceramic Society of Japan based on high marks given to NGK’s development and practical application of ceramics for purifying automotive exhaust.

The Ceramics Grand Prize is presented to individuals in recognition of their original and innovative achievements for inventions, development, or practical applications in the ceramics industry, or discoveries related to the science and technology of ceramics. It is the highest award presented by the Ceramic Society of Japan. NGK has made a significant contribution to reducing air pollution globally through its development and practical application of a wide range of porous ceramic products with a honeycomb design for purifying automotive exhaust. These products are based on NGK's core materials, forming and firing technologies cultivated in insulator manufacturing. In recognition of this major contribution, NGK has been selected as the winner of this prize. Ever since it was formed in 1988, the Ceramics Grand Prize has been awarded only when there is a qualified recipient. This is the second time that NGK has won the award, after receiving the 1st Ceramics Grand Prize. The award presentation ceremony will be held on June 7 in Tokyo.

Outline of Award

Name of award:

4th (FY2018) Ceramics Grand Prize

Organizer:

Ceramic Society of Japan

Awarded for:

Development and practical application of honeycomb ceramics for purifying automotive exhaust

Award recipients:

Hiroshi Kurachi, Hiroto Matsuda and Shinji Kawasaki of NGK INSULATORS, LTD.

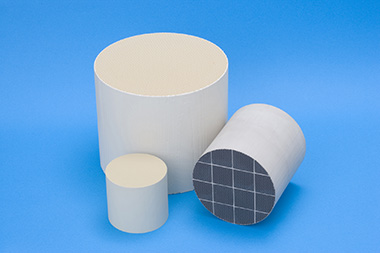

In 1971, automotive exhaust regulations entered force in the U.S. in response to increasingly serious air pollution problems. NGK took this opportunity to begin the development of HONEYCERAM, a ceramic catalyst carrier for gasoline vehicles that neutralizes the harmful substances in automotive exhaust, with mass production of HONEYCERAM commencing in 1976. Ever since, NGK has reduced the wall thickness of the honeycomb design in stages in order to improve the product’s exhaust cleaning performance in line with stricter exhaust gas regulations around the world. In recent years, NGK has successfully developed a HONEYCERAM design with walls as thin as a single sheet of tissue paper (approximately 0.05 millimeters), achieving both high cleaning performance and low pressure drop (low fuel consumption, high engine output). For diesel vehicles, NGK has developed a diesel particulate filter (DPF) that captures particulate matter (PM) more efficiently through control of the fine pore characteristics of ceramics. NGK has also developed a gasoline particulate filter (GPF) for gasoline vehicles by applying the materials, production and fine pore control technologies established through the development of DPF. In 2012, NGK brought GPF technology to the level of practical application for the first time in the world.

The Company currently produces ceramics for purifying automotive exhaust at 11 production sites in 9 countries around the world (a 12th production site is scheduled to start operations in December 2019). According to NGK's shipment records, NGK's products have been installed in around one in every two automobiles and trucks worldwide. This indicates that NGK is making a positive contribution to the preservation of the global environment. Going forward, NGK will continue working on the development and practical application of products that satisfy increasingly strict and widespread automobile exhaust gas regulations, with a view to contributing to the preservation of the global environment.