About NGK

History

PRODUCTS HISTORY

-

- 1919

- NGK INSULATORS, LTD. is established.

- 1923

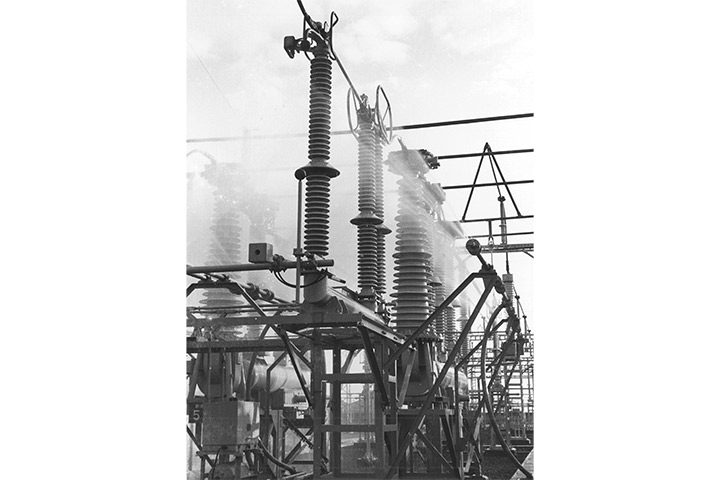

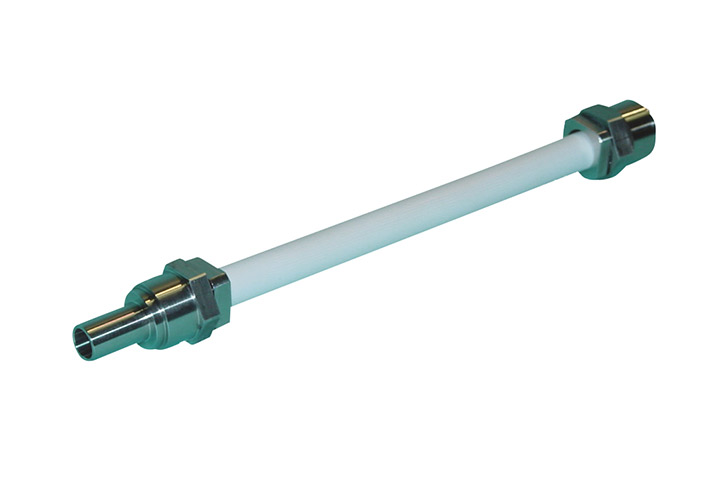

- Production of bushings begins.

- 1929

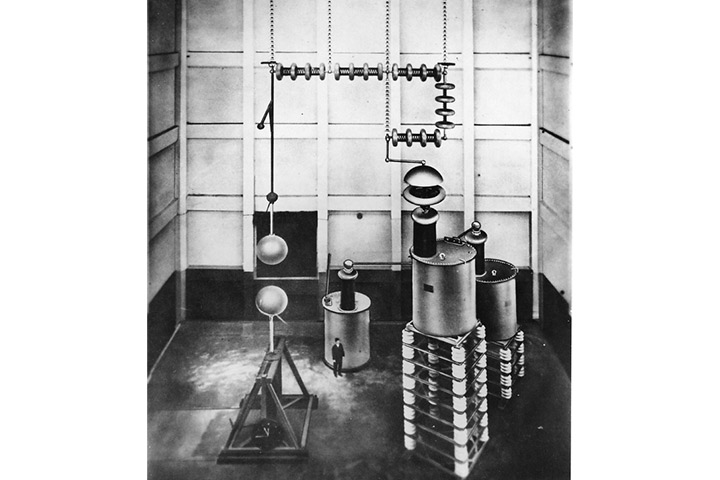

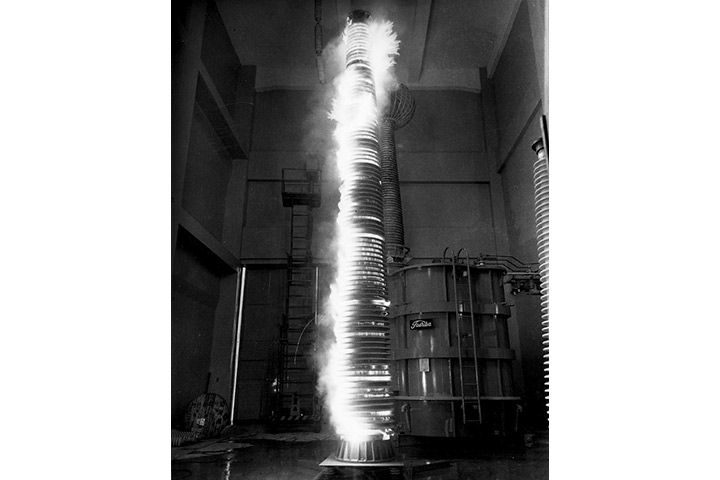

- Construction of a 1,000 kV-class high-voltage insulator test facility is completed.

- 1930

-

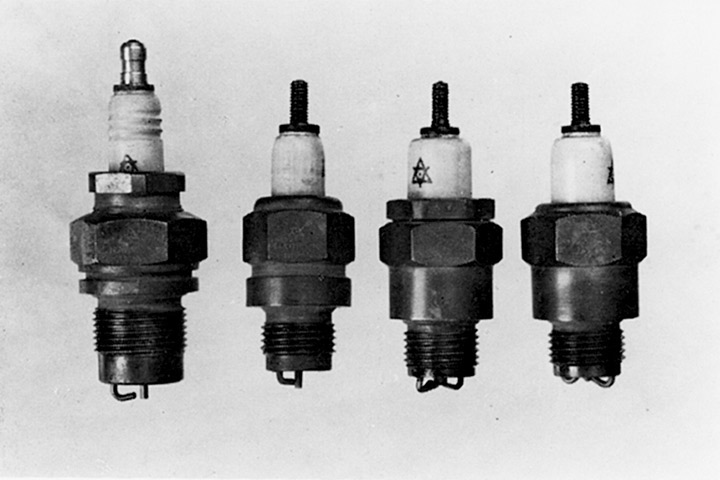

Manufacturing and sales of the “NG Spark Plug” begin.

Renamed the “NGK Spark Plug” in 1934.

Production transferred in accordance with the establishment of NGK Spark Plug Co., Ltd. in 1936.

Research on permeable substrates begins.

1,000kV-class high-voltage insulator test facility

NG Spark Plugs -

- 1931

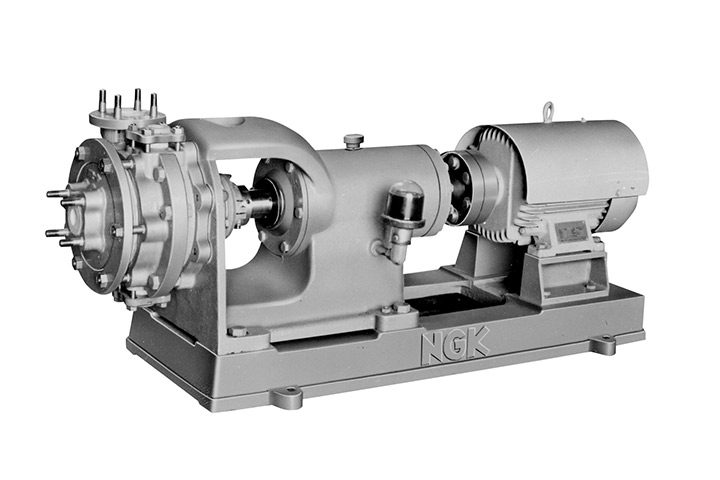

- First deliveries of acid proof pumps are made.

Production of acid-proof mortar begins.

- 1932

- Sale of laboratory porcelain ware begins.

- 1934

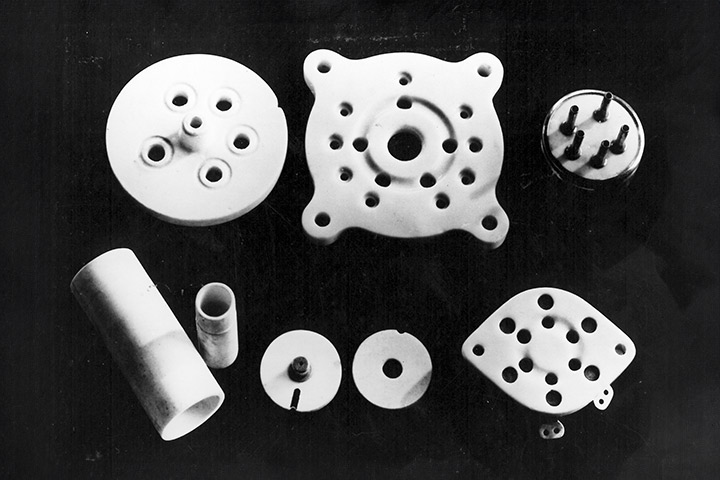

- First deliveries of ceramic diffusers are made.

- 1938

- Titanium porcelain is developed.

Acid proof pump

Ceramic diffusers -

- 1943

- Production of short-wave insulators begins.

Short-wave insulators -

- 1953

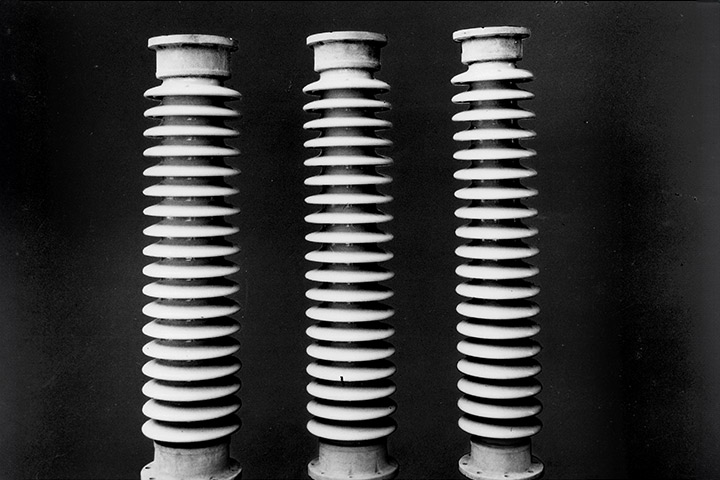

- Production of solid-core station post insulators begins.

- 1954

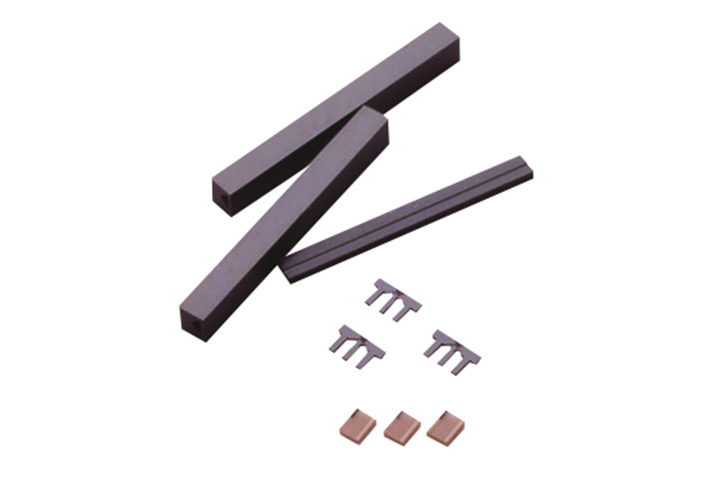

- Silicon carbide firing kiln shelves and supports are developed.

- 1955

- Research on Beryllium begins.

- 1958

- Manufacturing and sales of beryllium-copper master alloy begin.

Solid-core station post insulators

Beryllium-copper master alloy -

- 1961

- Long rod insulator is developed.

Dry-type capacitor bushing is developed.

- 1962

- Large hollow insulator (extrusion manufacturing) is developed.

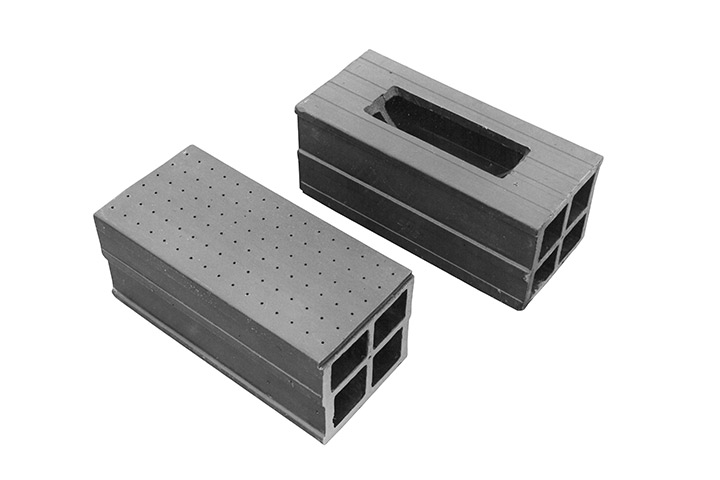

High-speed filtration tank underdrain (porous blocks) technology from Leopold (USA) is introduced.

- 1963

- First deliveries of Insulator Washing Equipment are made.

- 1967

- First deliveries of water sludge dewatering systems are made.

First deliveries of sewage sludge dewatering systems are made.

First deliveries of oxygen analyzers are made.

- 1968

- Transparent alumina ceramics HICERAM is developed.

- 1970

- First deliveries of industrial waste incinerators are made.

Porous blocks

Insulator Washing Equipment

Oxygen analyzer

Translucent alumina ceramics HICERAM -

- 1972

- Oil‐impregnated paper bushing for 1,000 kV-class test transformer is developed.

Glass lining manufacturing technology from De Dietrich (France) is introduced.

- 1973

- Ceramic road noise control equipment is delivered for the Meishin Expressway.

- 1974

- First deliveries of fluidized bed sewage sludge incineration systems are made.

First deliveries of roller hearth kilns are made.

Sales of molds for tires begins.

- 1976

- Production of ceramic substrates for automotive catalytic converters begins.

- 1977

- HONEYCERAM becomes a registered trademark.

- 1978

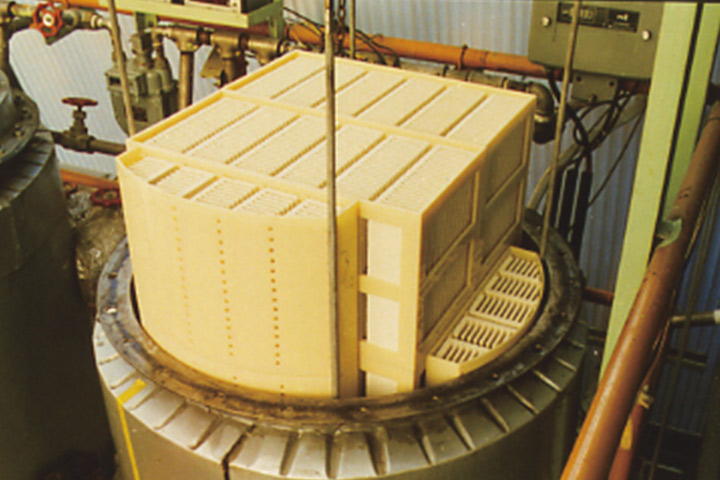

- First deliveries of low-level radioactive waste treatment equipment is made.

Sales of NGK Wall, an enamel wall panel, begin.

1,000 kV-class (ultra-high voltage) 70-and 84-ton suspension insulators are developed.

Fluidized bed sewage sludge incineration system

Mold for tires

Ceramic substrates for automotive catalytic converters HONEYCERAM

Low-level radioactive waste treatment equipment

NGK Wall, an enamel wall panel -

- 1981

- New production method for ferrite products for magnetic heads is developed.

- 1982

- Production of O2 sensors begins.

First deliveries of total area aeration systems are made in Okayama.

- 1983

- Ceramic filter for beer filtration is developed.

- 1984

- Research on beta alumina for sodium-sulfur batteries begins.

- 1986

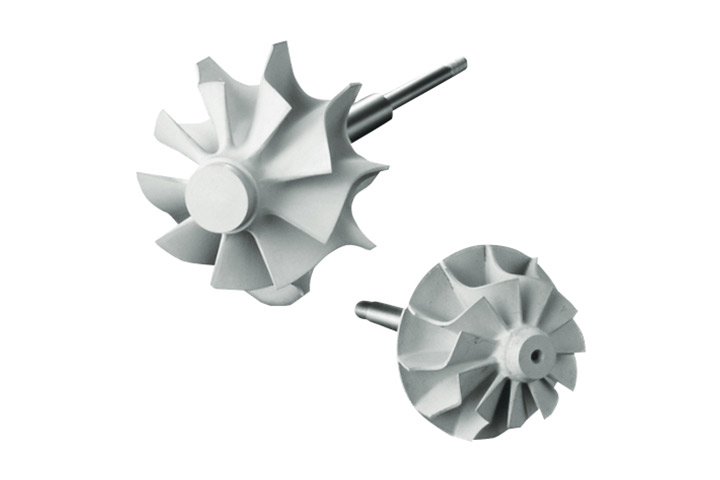

- First deliveries of ceramic turbocharger rotors are made.

Line arrester for power transmission lines is developed.

- 1987

- First deliveries of bioreactors are made.

Sound-absorbing material made from aluminum fibers is developed.

Research on sodium-sulfur batteries begins.

- 1989

- Production of diesel particulate filters (DPFs) begins.

- 1990

- First deliveries of the High-Pressure Compaction System for the treatment of non-combustible solid waste are made.

Ferrite products for magnetic heads

O2 sensors

Ceramic turbocharger rotors

Bioreactor

Diesel particulate filters (DPFs) -

- 1991

- First deliveries of cyclone-type sewage sludge melting systems are made.

- 1992

- Operation using a prototype NAS battery connected to the power grid begins.

- 1995

- Gas bushings for UHV transmission are productized.

Piezoelectric micro-actuator for inkjet printers is developed.

- 1996

- Mass production of ceramics for semiconductor manufacturing equipment begins.

NOx sensor for automotive exhaust is developed.

Induction-heat melting/solidification system is developed.

- 1997

- Mass production of optical waveguide devices for fiber optic gyroscopes begins.

Japan’s first ceramic membrane drinking water treatment system is developed.

- 1998

- Production of the Piezoelectric Micro-actuator for Inkjet Printers begins.

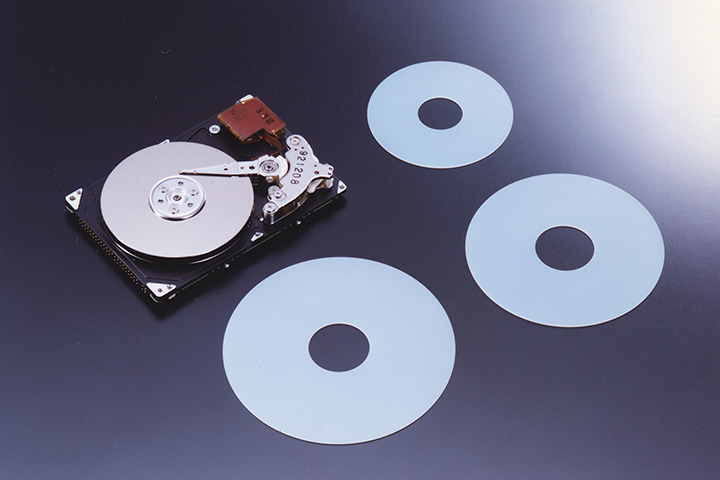

Mass production of glass ceramic substrates for hard disks begin.

- 1999

- Drying kilns and furnaces for manufacturing plasma display panels (PDPs) are developed.

Prototype NAS battery

Gas bushings for ultrahigh voltage transformers

Piezoelectric Micro-actuator for Inkjet Printers

Ceramics for semiconductor manufacturing equipment

Glass ceramic substrates for hard disks -

- 2001

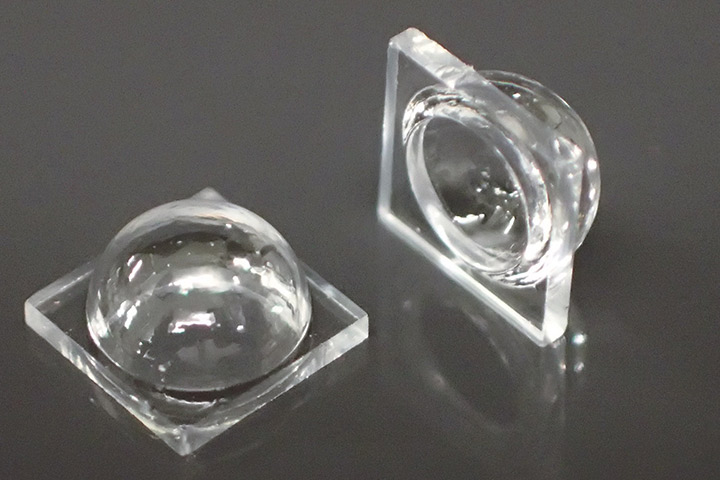

- SHG elements for high-power, high-performance blue lasers are developed.

Piezoelectric ceramic display is developed.

- 2002

- Home-use water purifier is launched.

MFI zeolite gas separation membrane is developed.

- 2003

- Mass production of NAS batteries begins.

- 2004

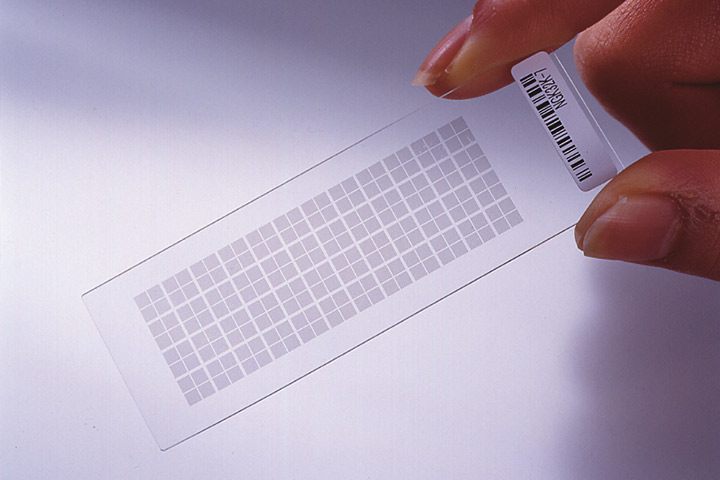

- DNA microarray for prognostic diagnosis of pediatric cancer is developed.

- 2005

- Piezoelectric micro-actuator for HDD heads is developed.

- 2006

- First overseas commercial operation of NAS battery begins at AEP (USA).

- 2007

- Subnano ceramic membrane is developed.

- 2008

- In-vehicle high-precision NOx sensor is developed.

- 2009

- Solid oxide fuel cell (SOFC) that uses a flat cylindrical cell (with built-in channels) is developed.

Atmospheric roller hearth kiln is developed.

Piezoelectric ceramic display

Home-use water purifier

MFI zeolite gas separation membrane

NAS batteries

DNA microarray for prognostic diagnosis of pediatric cancer

Subnano ceramic membrane

In-vehicle high-precision NOx sensor -

- 2011

- Home-use water purifier (slim type) is launched.

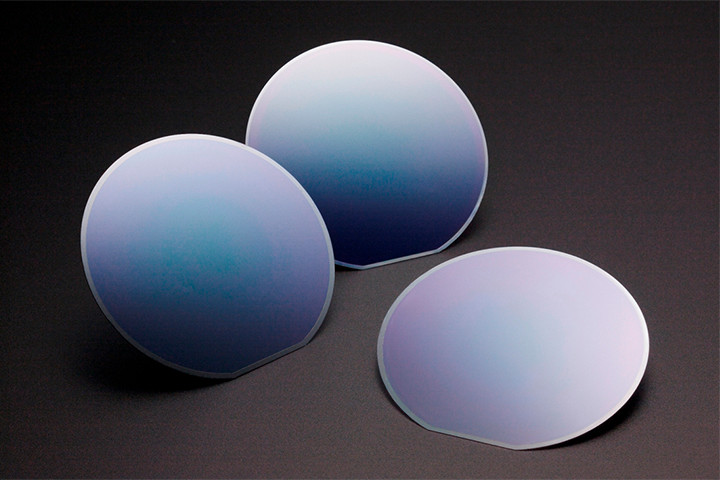

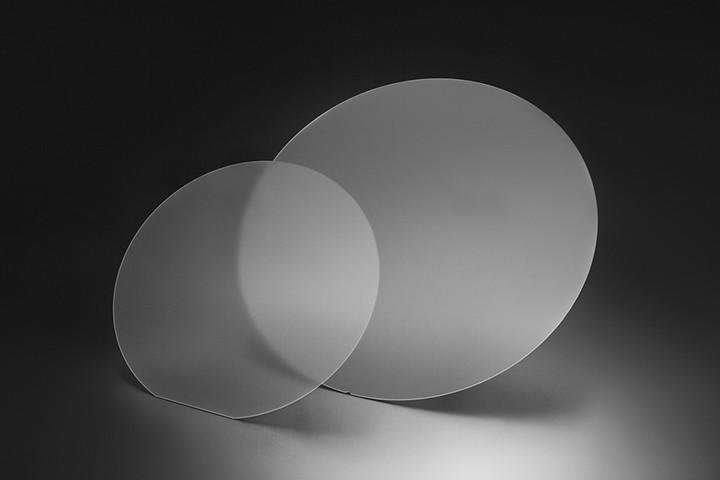

Bonded wafers for surface acoustic wave (SAW) filters are developed.

- 2012

- Gallium nitride (GaN) wafers for ultra-high brightness LEDs (light-emitting diodes) are developed.

Wavelength Control Drying System is developed.

Gasoline particulate filters (GPFs) are put to practical use.

- 2013

- Zirconium-copper wire is developed.

- 2015

- Containerized NAS battery is developed.

Ultra-compact piezoelectric micro-actuator for HDD heads is commercialized.

- 2018

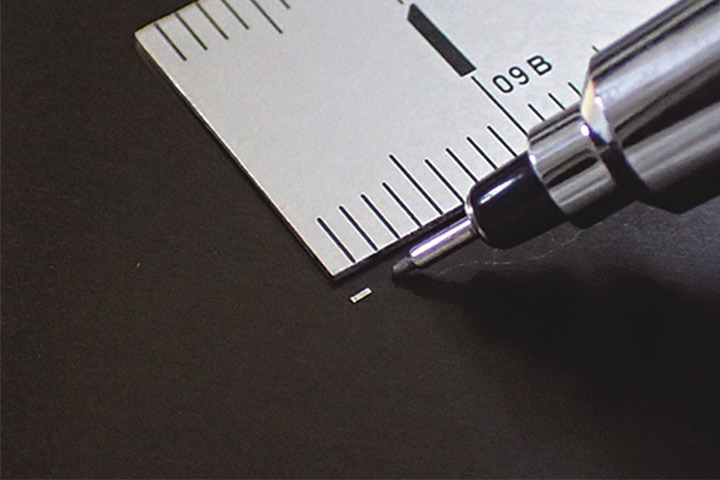

- Micro-lenses for ultraviolet LEDs are commercialized.

Gallium nitride (GaN) wafers for laser light sources are commercialized.

- 2019

- Chip-type ceramic secondary battery EnerCera series is commercialized.

Bonded wafers for surface acoustic wave (SAW) filters

Gallium nitride (GaN) wafers

Ultra-compact piezoelectric micro-actuator for HDD heads

Micro-lenses for ultraviolet LEDs

Chip-type ceramic secondary battery EnerCera series -

- 2025

- Cumulative production of HONEYCERAM reached 2 billion units.

COMPANY HISTORY

-

- 1919

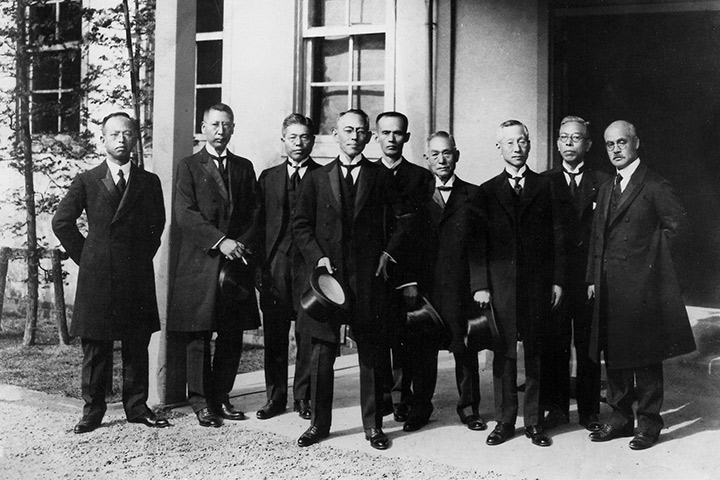

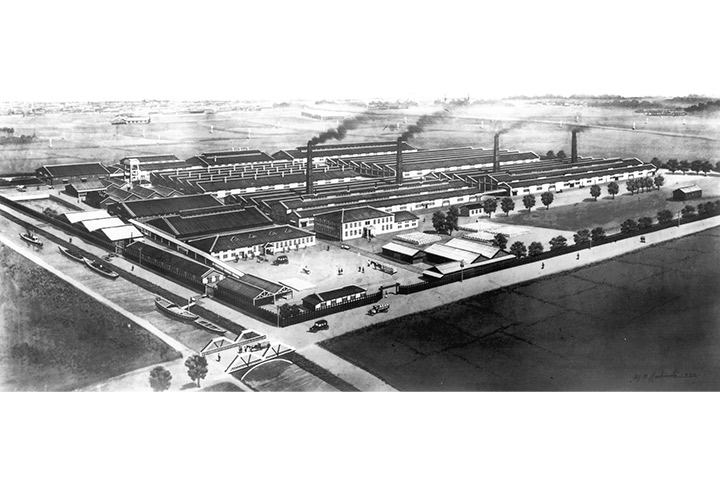

- NGK INSULATORS, LTD. is established as a spin-off from Nippon Toki’s Insulator Division.

Kazuchika Okura is appointed as president (the company’s first).

Directors at the time of the company’s founding (middle: president Okura)

Main plant at the time of the company’s founding -

- 1936

- NGK Spark Plug Co., Ltd. is established as a spin-off from NGK’s Spark Plug Division.

- 1939

- Magoemon Ezoe is appointed as president (the company’s second).

-

- 1942

- Construction of Chita Plant, located in Handa, Aichi, is completed.

- 1944

- Yoshiyuki Morimura is appointed as president (the company’s third).

- 1946

- The NGK Workers’ Union is started.

- 1948

- Kumao Yoshimoto is appointed as president (the company’s fourth).

- 1950

- Capital participation in Asahi Malleable Iron Co., Ltd. (present-day ASAHI TEC CORPORATION)

Chita Plant -

- 1951

- The 1st issue of Mizuho, the company newsletter, is published.

- 1956

- Capital participation in Fuji Yogyo (present-day NGK ADREC CO., LTD.).

The Indian liaison office is established (in Mumbai).

- 1957

- Atsuta Plant is completed.

An insulator plant in Mysore, India is completed with technical cooperation from NGK.

- 1959

- Sanji Nobuchi is appointed as president (the company’s fifth).

A divisional system is established, and the Chemical Engineering Machinery Department and New Product Division are established.

The 1st issue of Mizuho, the company’s internal newsletter

Insulator plant in Mysore, India

Atsuta Plant -

- 1961

- Capital participation in AKECHI INSULATORS CO., LTD. (present-day AKECHI INSULATORS, LTD.)

- 1962

- Construction of Komaki Plant, located in Komaki, Aichi, is completed.

The European liaison office is established (in Hamburg, West Germany).

The American liaison office is established (in New York).

- 1965

- NGK INSULATORS OF AMERICA, LTD. (present-day NGK-LOCKE, INC.) is established.

Capital participation in TAKAMATSU ELECTRIC WORKS, LTD (present-day ENERGY SUPPORT CORPORATION)

- 1968

- Construction of the High Voltage Laboratory is completed.

Bushing plant at Chita Plant is completed.

Capital participation in IKEBUKURO HORO KOGYO CO., LTD.

NGK INSULATORS OF CANADA, LTD. is established.

- 1969

- Katsumi Fukuta is appointed as president (the company’s sixth).

- 1970

- NGK exhibits its “Wind Mobile” jointly with Nippon Toki at Osaka Expo ’70.

Komaki Plant

High Voltage Laboratory -

- 1973

- LOCKE INSULATORS, INC. (USA) is established.

- 1974

- The Insulator Museum at the High Voltage Laboratory is completed.

- 1975

- Capital participation in Tochuberi Alloy Kogyo (present-day NGK METEX CORPORATION)

- 1976

- The brand logo is standardized to say “NGK,” and the corporate color is chosen.

The Tajimi Country Club opens.

The business group system is adopted. (Three business groups are established: Power, Machinery, and Special Products.)

- 1977

- Junichi Takemi is appointed as president (the company’s seventh).

NGK-BAUDOUR S.A. (Belgium) is established.

NGK EUROPE S.A. (N-E, Belgium) is established.

- 1979

- The UHV Contamination Test Hall at the High Voltage Laboratory is completed.

The Insulator Museum

NGK-BAUDOUR S.A.

The UHV Contamination Test Hall -

- 1984

- NGK Electronics is established.

- 1985

- NGK CERAMICS EUROPE S.A. (Belgium) is established.

NGK EUROPE GMBH (Germany) is established.

- 1986

- Toshihito Kohara is appointed as president (the company’s eighth).

The Japanese spelling of NGK INSULATORS LTD. is changed.

The corporate philosophy and a new corporate logo are established.

NGK METALS CORPORATION (USA) is established.

NGK NORTH AMERICA, INC. is established.

- 1987

- P.T. WIKA-NGK Insulators (Indonesia) is established.

- 1988

- NGK CERAMICS USA, INC. is established.

- 1989

- “K Plan 21,” NGK’s long-term management plan, is established.

NGK KILNTECH CORPORATION is established.

NGK CHEM-TECH, LTD. is established.

- 1990

- NGK OKHOTSK, LTD. is established.

NGK CERAMICS EUROPE S.A.

NGK METALS CORPORATION -

- 1991

- Capital participation in SOSHIN ELECTRIC CO., LTD.

NGK FILTECH, LTD. is established.

- 1993

- NGK STANGER PTY. LTD. (Australia) is established.

- 1994

- Masaharu Shibata is appointed as president (the company’s ninth).

NGK Printer Ceramics Co., Ltd. is established.

NGK-LOCKE POLYMER INSULATORS, INC. (USA) is established.

- 1996

- NGK FINE MOLDS, LTD. is established through a merger of NGK Molds and NGK Bealon, Ltd.

P.T. NGK CERAMICS INDONESIA is established.

NGK INSULATORS TANGSHAN CO., LTD. (China) is established.

- 1997

- “EXCEL‒01,” NGK’s medium-term management plan, is established.

SIAM NGK TECHNOCERA CO., LTD. (Thailand) is established.

- 1998

- Construction of NGK Printer Ceramics Yamanashi Plant (present-day NGK CERAMIC DEVICE Yamanashi Plant) is completed.

- 2000

- NGK CERAMICS SOUTH AFRICA (PTY) LTD. is established.

NGK STANGER PTY. LTD.

NGK-LOCKE POLYMER INSULATORS, INC.

SIAM NGK TECHNOCERA CO., LTD.

NGK CERAMICS SOUTH AFRICA (PTY) LTD. -

- 2001

- NGK CERAMICS SUZHOU CO., LTD. (ACC, China) is established.

NGK TECHNOCERA SUZHOU CO., LTD. (China) is established.

- 2002

- Shun Matsushita is appointed as president (the company’s tenth).

Management rights to FM INDUSTRIES, INC. (FMI, USA) are acquired.

NGK AUTOMOTIVE CERAMICS USA is established.

- 2003

- Shares of ASAHI TEC CORPORATION are transferred to a US investment fund.

NGK CERAMICS POLSKA SP. Z O.O. (ACP) is established.

Birla NGK Insulators Private Limited is established.

- 2005

- The board of directors is reformed, and a corporate officer system is introduced.

- 2006

- NGK INSULATORS SUZHOU CO., LTD. (NGK SUZHOU, China) is established.

- 2007

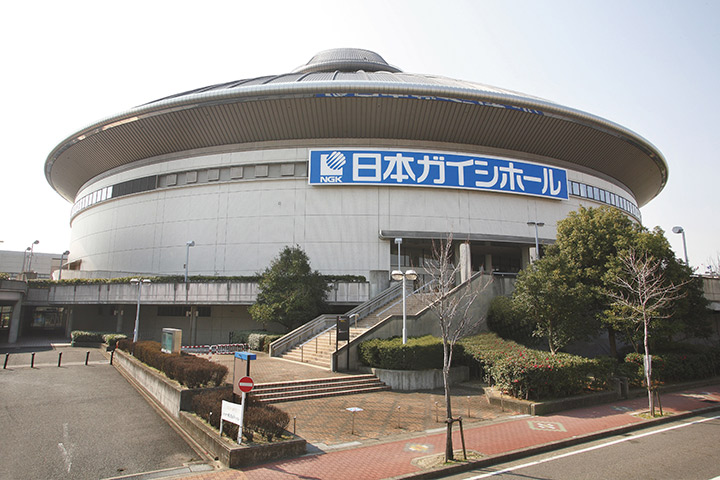

- NGK obtains the naming rights to Nagoya Civic General Gymnasium.

The Toba General Training Center is completed.

NGK Water Environment Systems, Ltd. is established.

NGK AUTOMOTIVE CERAMICS KOREA CO., LTD. is established.

A system of outside directors is introduced.

NGK INSULATORS UK, LTD. is established.

- 2008

- NGK CERAMICS MEXICO, S. DE R. L. DE C. V. is established.

The water environmental business is made into a subsidiary company with the establishment of METAWATER Co., Ltd.

NGK decides to construct a new facility for HONEYCERAM production in Nomi, Ishikawa.

- 2009

- Structural reform in manufacturing begins.

- 2010

- A representative office opens in New Delhi (India).

NGK CERAMICS SUZHOU CO., LTD.

NGK TECHNOCERA SUZHOU CO., LTD.

FM INDUSTRIES, INC.

NGK CERAMICS POLSKA SP. Z O.O.

Nagoya Civic General Gymnasium after obtaining naming rights

NGK CERAMICS MEXICO, S. DE R. L. DE C. V.

Ishikawa Plant -

- 2011

- Taro Kato is appointed as president (the company’s eleventh).

NAS battery fire incident occurs.

NGK Group Guidelines for Corporate Behavior is revised.

- 2012

- NGK is recognized as a company that supports parenting by the Ministry of Health, Labour and Welfare.

FMI purchases a business involved in semiconductor manufacturing equipment from a US manufacturer.

NGK decides to build a new large-size HONEYCERAM plant at ACP.

- 2013

- The Competition Law Handbook is published.

- 2014

- Taku Oshima is appointed as president (the company’s twelfth).

NGK decides to dissolve NGK SUZHOU.

NGK decides to carry out mass production of gasoline particulate filters (GPFs) at ACP.

- 2015

- NGK ELECTRONICS DEVICES, INC. becomes a group company.

NGK decides to build a new facility, the second ACP plant.

NGK decides to build a new NOx sensor element plant in Ishikawa.

NGK TECHNOLOGIES INDIA PVT. LTD. is established.

NGK CERAMICS (THAILAND) CO., LTD. is established.

NGK enters into a plea agreement with the US Department of Justice (DOJ) regarding an antitrust law violation in connection with some of its transactions involving ceramic substrates for automotive catalytic converters.

- 2016

- Gasoline particulate filters (GPFs) production at ACC is announced.

- 2017

- FM INDUSTRIES, INC. establishes a new plant.

The human resource system for general office workers is revised for the first time in 25 years.

A retirement age of 65 is adopted.

NGK decides to build a new plant facility for ceramic products for semiconductor manufacturing equipment in Tajimi, Gifu.

NGK decides to dissolve LOCKE INSULATORS (USA).

NGK decides to build the second ACC plant.

- 2018

- The Process Technology Business Group is established, as the company changes to a four-business-group system.

NGK holds a press conference regarding the Non-Conformity in Testing Procedure.

Sensory training begins at the Sensory Hazard Prediction Training Center.

- 2019

- The NGK Group Code of Conduct is revised.

The NGK Group Philosophy is announced.

The decision is made to dissolve NGK TANGSHAN.

Antitrust Laws Compliance Handbook

NGK CERAMICS (THAILAND) CO., LTD.

NGK CERAMICS DEVICE Tajimi Plant

ACC second plant

Sensory Hazard Prediction Training Center -

- 2021

- Shigeru Kobayashi is appointed as president (the company’s thirteenth).

Formulated NGK Group Vision: Road to 2050 as a mid-to long-term vision.

- 2023

- Revised the NGK Group Corporate Business Principles and established the NGK Group Code of Conduct.

This content of this page is current at the time of publication. Please note that company and product names may differ from the latest information.