Product

Zinc Rechargeable Battery Cell Acquires the World's First-Ever UL Verification Mark in the Battery Energy Storage Systems Field

November 19, 2019

Realizing a safe and large-capacity battery energy storage system optimal for indoor installation utilizing unique ceramics technology

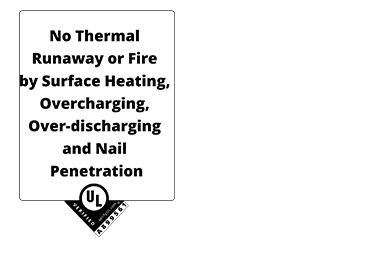

NGK INSULATORS, LTD. (hereinafter "NGK") based in Nagoya, Japan, announced that its Zinc rechargeable battery, which is currently under development, acquired the world’s first UL verification mark in the battery energy storage systems field as a result of testing based on c the UL 9540A standard by UL (Headquarters: Northbrook, Illinois), an independent global safety science organization in the United States. UL 9540A is a Test Method for Evaluating Thermal Runaway Fire Propagation in Battery Energy Storage Systems. Zinc rechargeable battery’s high safety performance has been demonstrated through the objective and highly reproducible verification process undertaken by UL.

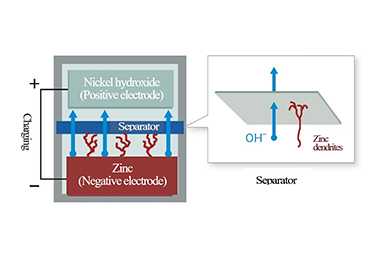

NGK is currently developing Zinc rechargeable battery as a battery energy storage system (rechargeable battery) that realizes high safety and large energy storage capacity, making it optimal for indoor installation. This has been achieved by using zinc as the negative electrode, aqueous solution as the electrolytic solution, and NGK’s unique ceramic separator as a barrier between the positive and negative electrodes.

Batteries that employs zinc as the negative electrode have a high energy density. This has allowed zinc batteries to be widely used as single-use, non-rechargeable batteries, such as alkaline batteries and air cells for hearing aids, etc. However, when zinc is used as the negative electrode of a rechargeable battery, the zinc will form dendrites on the negative electrode during charging. The dendrites will then pierce the separator and will cause a short circuit. For many years, this problem has hindered the progress on the commercialization of zinc rechargeable batteries. NGK has solved this problem by developing a new highly densified ceramic separator with hydroxide (OH-) ion conductivity. As a result, NGK has succeeded in developing a zinc rechargeable battery. The new ceramic separator developed by NGK allows only the hydroxide (OH-) ions, which are essential for battery operation, to pass, while physically blocking the dendrites, thereby preventing short circuits between the positive and negative electrodes. The separator has thus made it possible for the battery to undergo repeated charging and discharging cycles. This is the first case that a ceramic separator is used for a zinc rechargeable battery.

Zinc rechargeable battery offers a high energy density and compact installation, and the battery can be operated at room temperature. In addition, Zinc rechargeable battery does not have the risk of internal fire or thermal runaway as it employs a nonflammable aqueous solution as an electrolytic solution. Therefore, Zinc rechargeable battery features high safety, and it is also optimal for indoor installation. There is a strong needs for battery energy storage systems that offers both high safety and large energy storage capacity at schools and hospitals, retail facilities such as convenience stores, and facilities where business continuity planning (BCP) measures are crucial, such as base stations and communications buildings. NGK envisions that Zinc rechargeable battery will be adopted for use in such facilities.

The UL 9540A standard establishes test methods to confirm what could happen if there were a thermal runaway within a battery energy storage system. The standard was developed by UL at the request of fire departments and fire protection organizations in the United States. It has now gained a high level of trust around the world, not only in the United States, where strict safety standards are required. The UL 9540A tests are conducted to confirm the risks associated with fire, flaming, fragment dispersion, fuming, and flammable gas generation. It has been confirmed that NGK’s Zinc rechargeable battery will not cause thermal runaway or fire, as a result of surface heating, overcharging, over-discharging and nail penetration tests carried out at the cell* level in accordance with UL 9540A test methods. Based on these results, NGK will promote Zinc rechargeable battery as a product that is optimal for installation in places where a high degree of safety is required, such as indoors.

There has been heightened interest in the effective use of renewable energy, peak shaving for electric power, securing electric power during disasters, and BCP measures. Against this backdrop, the demand for battery energy storage systems has been expected to grow in recent years. Since 2015, NGK has been working to develop Zinc rechargeable battery into a product featuring advanced fire safety performance, large energy storage capacity, and long life. NGK has been pushing ahead with efforts to commercialize Zinc rechargeable battery at the earliest opportunity. Notably, in 2016, the Ceramics Battery Project was formed as a company-wide project with participation from various parts of the company, including the corporate R&D and the Corporate Manufacturing Engineering and Sales and Marketing Divisions, along with the Intellectual Property and Purchasing Departments. With the acquisition of the UL verification mark, NGK will further accelerate development and demonstration tests, with plans to commercialize Zinc rechargeable battery in fiscal year 2020.

- *Cell: the smallest battery unit installed within a battery energy storage system. Refers to a single cell.

Features of zinc rechargeable battery

High safety:

An aqueous solution is used as an electrolytic solution, rather than a flammable organic solvent. Therefore, Zinc rechargeable battery offers high safety and highly flexible options for installation sites.

Large energy storage capacity:

Realizes high energy density equal to a stationary type lithium-ion battery.

(Approximately 200 Wh per liter of battery volume)

About NGK

NGK is the world’s largest manufacturer of electrical insulators, including 1,000-kV ultrahigh-voltage (UHV) transmission and substation insulators, and has a 100-year history. With foundations in exclusive ceramics technology, NGK contributes to environmental conservation, providing a wide range of products and technology in the “Triple E” growth fields of energy, ecology and electronics. NGK is also one of the largest manufacturers of HONEYCERAM and diesel particulate filters (DPFs) for catalyst converters for automobiles. NGK is also the world’s leading manufacturer succeeding in commercialization of large-capacity energy storage systems (NAS batteries), which has overturned the conventional wisdom that power cannot be stored. Its President is Taku Oshima.

About UL

UL helps to create a better world by applying science to solve safety, security and sustainability challenges. UL empowers trust by enabling the safe adoption of innovative new products and technologies. Everyone at UL shares a passion to make the world a safer place. All of UL’s work, from independent research and standards development, to testing and certification, to providing analytical and digital solutions, helps improve global well-being. Businesses, industries, governments, regulatory authorities, and the public put their trust in UL so they can make smarter decisions.

About UL

About UL Japan

UL Japan was established in 2003 as a Japanese subsidiary of UL, a global independent safety science company. Currently, UL Japan harnesses UL’s global network to provide conformity assessment services for the UL mark in North America, as well as the PSE Marks and S-Mark for safety and EMC verification based on Japan’s Electrical Appliances and Materials Safety Act, and verification marks required by products for the European and Chinese markets.

About UL Japan