Product

CO2 Separation Membrane Developed for Industrial Exhaust Gas

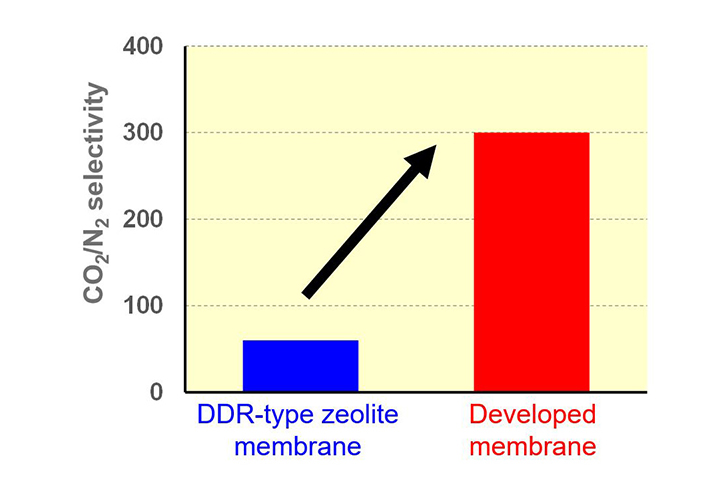

Confirmed Approximately Five Times the Separation Factor of DDR-Type Zeolite Membrane

November 12, 2021

NGK INSULATORS, LTD. (“NGK”) has developed a carbon dioxide (CO2) separation membrane for industrial exhaust gas. In testing with simulated industrial exhaust gas, the membrane achieved CO2 separation factor approximately five times that of conventionally developed DDR-type zeolite membrane used for CO2 separation. The Company aims to continue with development for further increases in separation performance, aiming for commercialization in 2030 after demonstration testing.

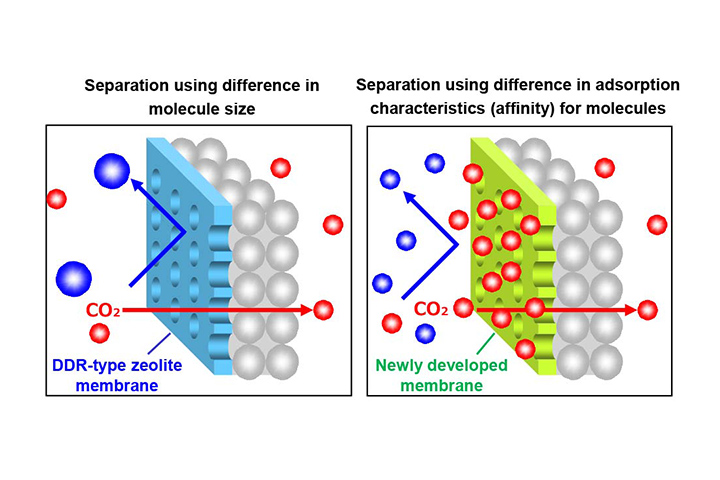

The conventionally developed DDR-type zeolite membrane can be used for CO2 separation using differences in molecule size. It is easily able to separate CO2 in associated gas and natural gas, since methane, their major component, has a larger molecule size than CO2. On the other hand, in industrial exhaust gas, the major components are nitrogen and oxygen, which have molecule sizes similar to CO2. Therefore, it is difficult to precisely separate CO2 from industrial exhaust gas using a DDR-type zeolite membrane. The newly developed CO2 separation membrane for industrial exhaust gas makes use a difference in adsorption characteristics (affinity) for molecules to separate CO2 from nitrogen and oxygen, which increases CO2 separation factor. In testing uses simulated industrial exhaust gas, the new membrane was confirmed to have approximately five times the CO2 separation factor of a conventionally developed DDR-type zeolite membrane. Using the characteristics of ceramics, which can be used under harsh conditions, the Company is working to increase the separation factor even further for high temperature industrial exhaust gases, aiming for commercialization in 2030 after demonstration testing.

In April 2021, the NGK Group formulated the NGK Group Environmental Vision. The vision calls for 50% reduction in CO2 emissions compared with fiscal 2013 by fiscal 2030 and aims to achieve net zero emissions by fiscal 2050. Through the development and provision of various membrane technologies going forward, NGK will work to reduce CO2 emissions through the spread of technologies for the separation, recovery, and effective use of CO2, and contribute to the realization of carbon neutrality.