Products

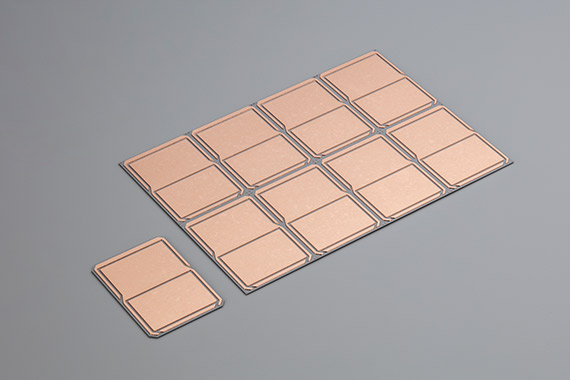

AMB Substrates for Power Modules

Product tags:

Overview

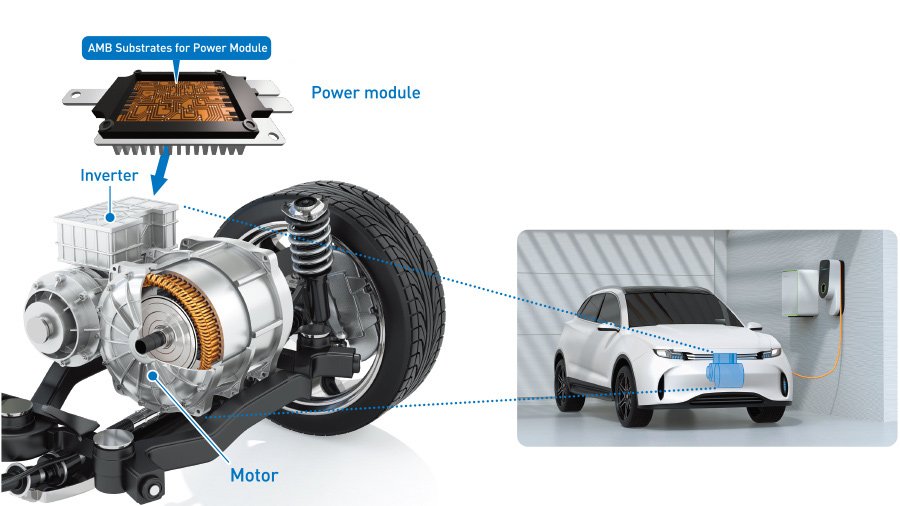

Active Metal Brazing (AMB) substrates for Power Modules enable efficient and stable operation in inverter control devices, releasing the heat which is generated by the built-in power semiconductor.

Features

AMB Substrates for Power Modules are products in which copper plates are bonded to each surface of a ceramic plate, which is an insulating material.

We offer Silicon Nitride-based ceramic materials.

Through bonding by the AMB method, the Silicon Nitride-based ceramic plate is integrated with the copper plate.

Those products are characterized by a high thermal conductivity and a high electric conductivity of copper, and also a high insulation property of ceramic substrate.

In the AMB method, a bonding layer with a thickness of several microns or less is achieved, the advantage being there is almost no effect on thermal resistance.

Application

- Various power modules in which power semiconductor chips, such as Si-IGBT and SiC-MOSFET, are mounted

- Power module units for electric vehicles

- Renewable energies (wind power, photo voltaic power generation, etc.)

- Inverters for industrial use

Inquiry about Electronic Components

Please apply with the contact form and give us your comments or questions.