Product

NGK decides to increase Production Capacity of AMB substrates for Power Semiconductor Modules by approximately 2.5 times

March 07, 2024

NGK INSULATORS, LTD. (hereinafter “NGK”) based in Nagoya, Japan, has recently decided to augment production capacity of AMB substrates for power modules. By the fiscal year 2026, monthly production will be increased by about 2.5 times from the current capacity. NGK aims for net sales of 20.0 billion yen by the fiscal year 2030, by improving supply capacity and by steadily capturing demand in markets such as automotive applications, which is expected to grow in the future.

Currently, AMB substrates for power modules, which are made from Silicon Nitride, are manufactured by NGK’s subsidiaries. NGK CERAMIC DEVICE CO., LTD. (“NCDK”), based in Komaki, Aichi Prefecture, handles the front end-processing such as bonding, whereas NGK ELECTRONICS DEVICES, INC., based in Mine, Yamaguchi Prefecture, and NGK ELECTRONICS DEVICES (M) SDN.BHD., based in Penang, Malaysia, handles the back end-process such as etching and plating. NGK’s investment will augment facilities at NCDK and NGK ELECTRONICS DEVICES (M), increasing the monthly production capacity from its current level of roughly 100,000 AMB substrates to approximately 250,000 AMB substrates in the fiscal year 2026. The planned investment amount will be approximately 5.0 billion yen.

Moreover, to prepare for further increased demand, and to strengthen the supply chain to the main markets of power module, NGK is currently planning additional production base in Europe.

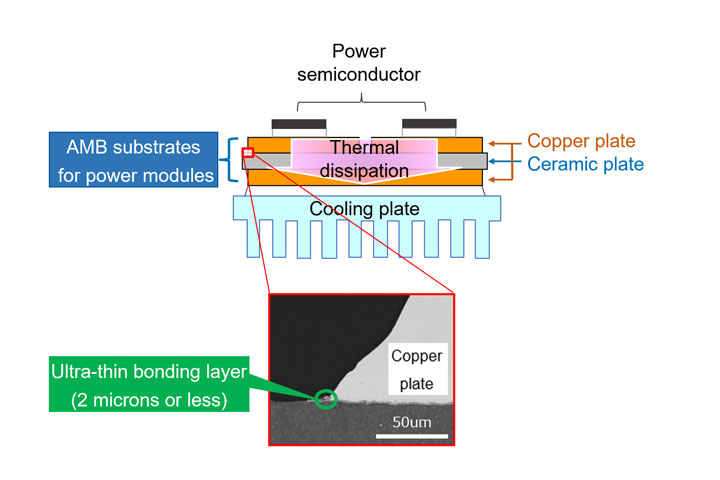

AMB substrates for use in power modules, perform roles such as controlling motor drive and converting power in generators. By dissipating heat generated when power semiconductors are operated, the substrates for power modules play a central role in providing stable operation. AMB substrates for power modules made of Silicon Nitride are used in applications such as inverters for motor control in Battery Electric Vehicles (BEV) and Hybrid Electric Vehicles (HEV), as well as being increasingly used in Silicon Carbide (SiC) power semiconductors, which require stability even in high power and high temperature environments. NGK’s Silicon Nitride AMB substrates, which achieve high reliability and excellent heat dissipation characteristics through proprietary bonding technology, have been adopted by several European and Japanese power module manufacturers since 2019, and have been recognized as a product which can maximize the performance of power modules. Demand from automotive application is expanding in conjunction with the global growth of xEVs, and the outlook for this market is positive over the medium- to long-term.

NGK Group’s mid- to long-term vision, targeting 2050, states that the Group will transform the current business structure to the fields of Carbon Neutral and Digital Society. In the commitment of “New Value 1000”, NGK aims to generate at least 100.0 billion yen in net sales from the new business fields by the milestone year of 2030. AMB substrates are expected to contribute to Carbon Neutrality through automotive applications in BEV and HEV, as a key component of power modules. NGK will continue to focus on the Carbon Neutrality and Digital Society fields and contribute to resolving social issues through its proprietary ceramic technologies.

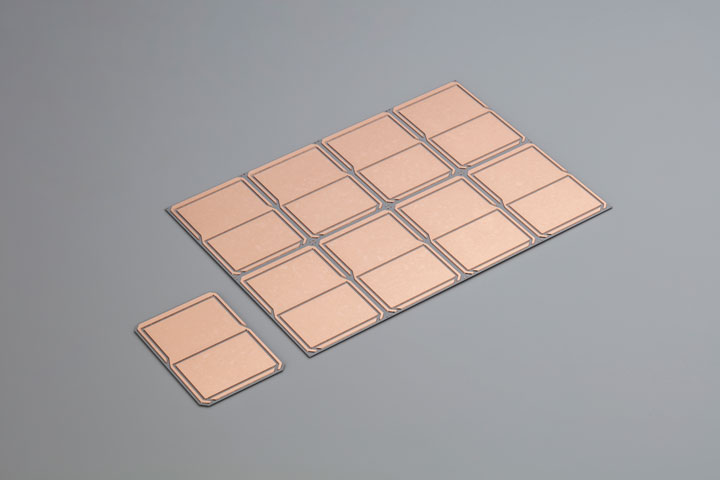

Silicon Nitride insulation/thermal dissipation circuit ceramic substrates (AMB substrates)

AMB substrates are comprised of a ceramic plate made of nitride-based material and two copper plates. Using NGK’s proprietary, advanced bonding technology, it is possible to make the bonding layers between the ceramic and copper with an extremely thin structure of just a few microns. This greatly reduces the thermal resistance and internal strain in the bonding layer, resulting in high reliability and excellent thermal dissipation characteristics.

Product information on AMB and DCB Substrates for Power Modules