Products

The Antistatic System for Ultrapure Water (MEGCON)

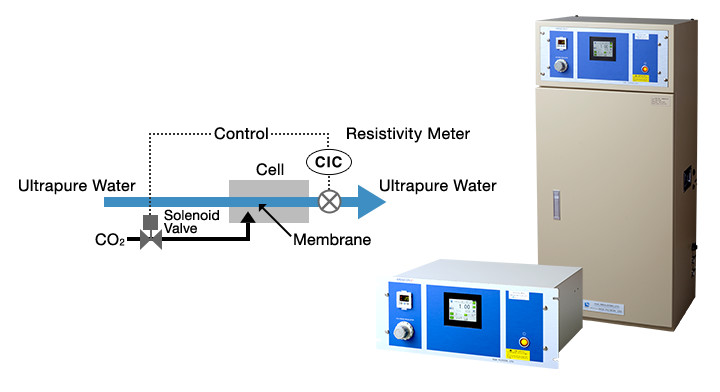

"MEGCON Ⅱ+" is the equipment that controls the resistivity value of ultrapure water by dissolving carbon dioxide gas in ultrapure water through special hollow-fiber membrane.

Overview

In the precision cleaning of semiconductor products, ultrapure water is used that is almost free of ion component. Therefore, static electricity can easily generate and the following errors cause product defect.

- Destruction of substrate circuit (ESD damage)

- Particle reattachment

With MEGCONⅡ+, by reducing the resistivity value of ultrapure water and giving it conductivity,

it is possible to prevent defects caused by this static electricity.

Applications

- Dicing process

- High Pressure jet cleaning

- Scrubber cleaning

- Liquid crystal process

- Mask and reticle cleaning

Features

- Low risk of particle contamination and small amount of CO2 gas consumption

- Possible to control even in the case of small flow rate

- Low pressure loss

- Automatic control of resistivity value

- Line-up large flow rate models

Principle

Control the resistivity value of ultrapure water by dissolving carbon dioxide gas in ultrapure water through special hollow-fiber membrane.

MEGCONⅡ+ "PRC Series" Model and Specifications

| Series | Cabinet type | >Air pump built-in type "PRCⅡ+ - (Below model number)" | |||||

|---|---|---|---|---|---|---|---|

| Model | Standard | 1000ACD | 1200ACD | 2000ACD | 1220ACD | 2040ACD | |

| S type*2 | 1000ACD-S | 1200ACD-S | 2000ACD-S | 1220ACD-S | 2040ACD-S | ||

| Performance | Max. flow rate L/hr | 1000 | 1000 | 2000 | 2000 | 4000 | |

| Control area *1 MΩ·cm | 0.2-2.0 | 0.1-0.5 | 0.2-2.0 | 0.15-1.0 | 0.2-2.0 | ||

| Dimensions | Standard | 520W×400D×1150H mm | |||||

| S type *2 | 520W×400D×1415H mm | ||||||

| Weight | Standard | 65kg | 70kg | ||||

| S type *2 | 66kg | 71kg | |||||

| Wetted part | Cell (carbon dioxide gas induction part) : PP | Cell (carbon dioxide gas induction part) : PP | |||||

| Material | Piping : PVC, blade hose | Piping : PVC | |||||

| Ultrapure water Connection gauge | Rc1/2 | Rc3/4 | Rc1 1/4 | ||||

| Utility | Ultrapure water | Pressure : Regular 0.35MPa and below (Max 0.45MPa and below) / Temperature : 5~35°C / Water : 10MΩ·cm and above | |||||

| CO2gas | Pressure : 0.1~0.2MPa / Temperature : 5~35°C / Ultrapure water : 99.5% and above | ||||||

| Dry air (for membrane drying) | Not required because air pump is built-in | ||||||

| Electric power source | AC100-240V (50/60Hz) | ||||||

| Standard accessory | Instructions manual, test report | ||||||

| AC100-120V : Electric power cord 2.8m(with plug) | |||||||

| AC200-240V : Electric power cord 5m(without plug) | |||||||

| Series | Rack type | Air pump built-in type "PRCⅡ+ - (Following model number)" External air supply type "FRCⅡ+ - (Following model number)" |

|||

|---|---|---|---|---|---|

| Model | 1000AD | 1200AD | 2000AD | 1220AD | |

| Performance | Max. flow rate L/hr | 1000 | 1000 | 2000 | 2000 |

| Control area*1 MΩ・cm | 0.2-2.0 | 0.1-0.5 | 0.2-2.0 | 0.15-1.0 | |

| Dimensions | 480W×355D×200H mm | ||||

| Weight | 15kg | ||||

| Wetted part | Cell(carbon dioxide gas induction part): PP | ||||

| Material | Piping : PVC,blade hose | ||||

| Ultrapure water connection gauge | Nozzle for hose(IDφ19 for blade hose) | ||||

| Utility | Ultrapure water | Pressure : Regular 0.35MPa and below (Max 0.45MPa and below) / Temperature : 5~35°C / Water : 10MΩ·cm and above | |||

| CO2gas | Pressure : 0.1~0.2MPa / Temperature:5~35°C / Ultrapure water:99.5% and above | ||||

| Dry air(for membrane drying) | "PRC" series : Not required because air pump is built-in | ||||

| "FRC" series : 0.1~0.2MPa | |||||

| Electric power source | AC100-240V (50/60Hz) | ||||

| Standard accessory | Instructions manual, test report | ||||

| AC100-120V : Electric power cord 2.8m(with plug) | |||||

| AC200-240V : No cord(please connect to the terminal) | |||||

- *1Maximum resistivity value is the value achieved when the flow rate is about 500L/hr.

- *2-S type includes a 2-color lamp with buzzer + caster with levelers.

- *Water Pressure : Regular 0.35MPa (Maximum 0.45MPa and below).

- *The specifications and other information listed here may be changed without notice.

Inquiry about Ceramic Membranes & Separators

Please apply with the contact form and give us your comments or questions.