Beryllium Copper Strip (Strip, Plate, Rod and Wire forms)

Widely used to form contact springs, these products are available as strips, plates, rods, or wire. Choose from a variety of alloy grades and hardnesses for specific applications.

Products

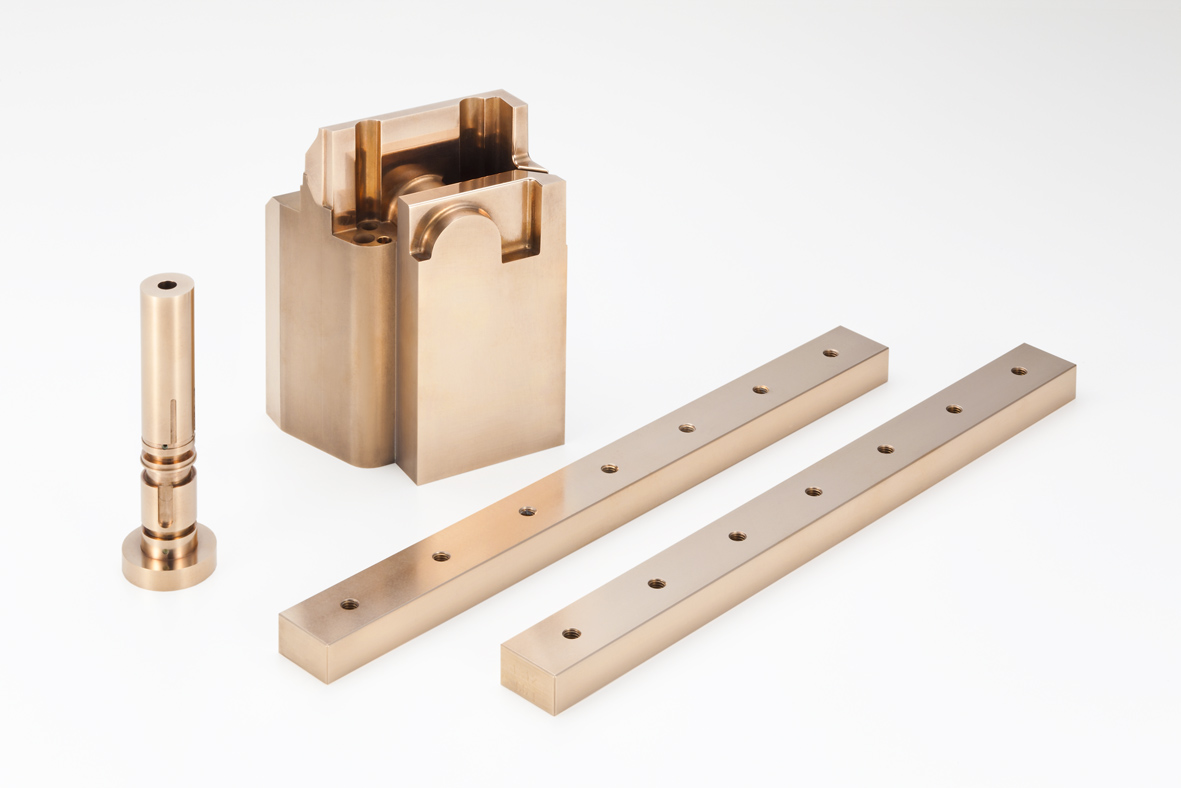

Whereas NGK supplies beryllium and beryllium copper products as "raw material" for customers, we also provide these materials in finished shape according to customers' request. With expertise in material process and characters, NGK produces the finished shape at its maximum performance.

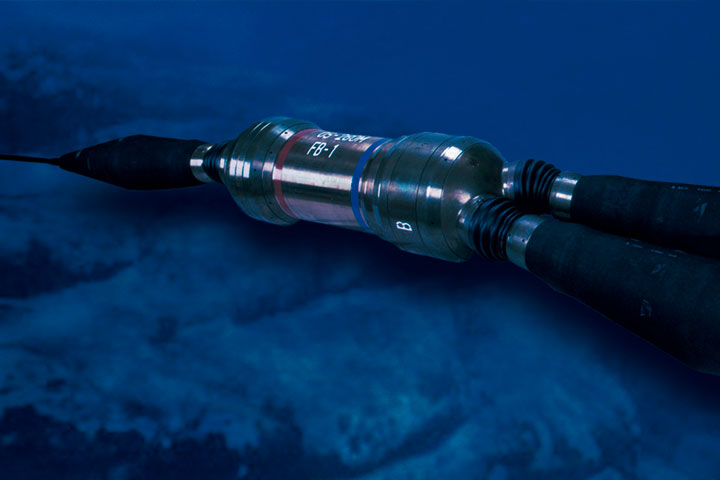

The signals of undersea optical fiber communication cables used for international telephone transmission have been weakened as the signals go forward. In order to re-strengthen the signals, the repeaters are placed at certain intervals. The beryllium-copper is applied as the material of the repeater housing, which requires severe properties, such as corrosion-resistance against seawater and high-strength.

| Product Type | Characters | Applications |

|---|---|---|

| Electrode | High Strength Electrical Conductivity |

Bat Welder Spot Welding Holder Gun Arm Welding Socket, Adapter |

| Mechanical Parts | High Strength Wear Resistance Corrosion Resistance |

Aircraft Bushing Die Cast Machine Plunger Tip Cutting Blade for Crusher |

Inquiry about Special Metals

Sales & Marketing Division