Chill Vent

Chillers are used to vent gas in the high-pressure die casting of molded aluminum or magnesium parts.

Products

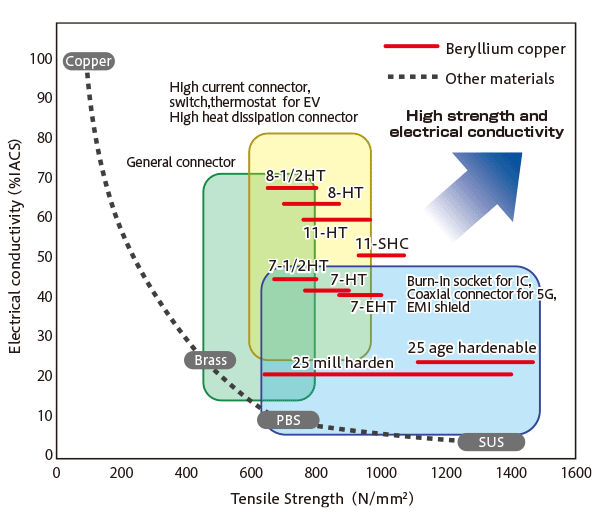

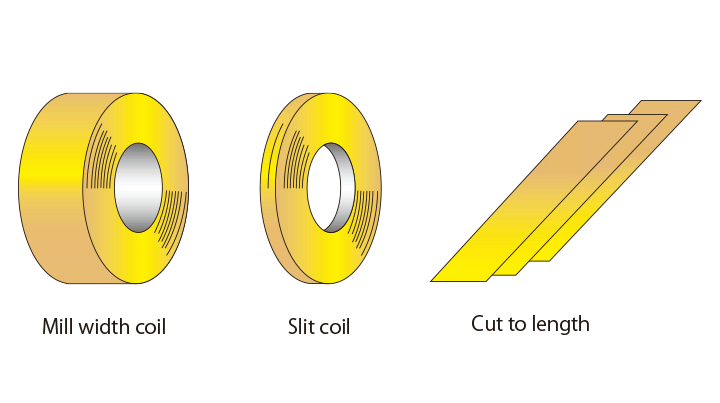

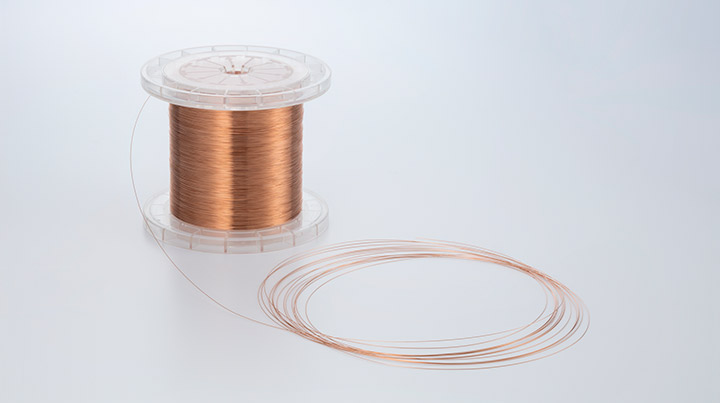

Widely used for contact springs, these core NGK products, available as strips, plates, rods, or wire, offer an ideal combination of properties such as tensile strength, electrical conductivity, fatigue strength, thermal stability, bending formability, and corrosion resistance.

Beryllium Copper is a copper alloy with the optimum combination of mechanical and physical properties such as tensile strength, fatigue strength, performance under elevated temperatures, electrical conductivity, bending formability, corrosion resistance and non-magnetic. Beryllium Copper is widely used as contact springs in various applications like connectors, switches, relays, etc. NGK offers a variety of Beryllium Copper alloys in several tempers to cover different applications. Our Beryllium Copper products are available in strip, plate, rod and wire forms.

Note: These are typical values as measured by NGK. They do not constitute guarantees.

| NGK Alloy | Chemical Composition [wt%] | |

|---|---|---|

| Alloy 25 | Be Ni+Co Ni+Co+Fe Cu+Be+Ni+Co+Fe |

1.80-2.00 0.20min. 0.6max. 99.5min. |

| Alloy 8 Alloy 11 |

Be Ni Cu+Be+Ni |

0.20-0.60 1.40-2.20 99.5min. |

| Alloy 7 | Be Ni+Co Al Cu+Be+Ni+Co+Al |

0.20-0.40 1.80-2.50 0.6max. 99.0min. |

The chemical composition of beryllium copper alloys is tested using optical atomic emission spectrometry as specified by NGK. Cu is considered the remainder after subtracting other elements.

| Item | NGK Alloy 25 | NGK Alloy 8·11 | NGK Alloy 7 |

|---|---|---|---|

| Melting Point (solidus) [℃] | 865 | 1004 | 1050 |

| Melting Point (liquidus) [℃] | 980 | 1070 | 1081 |

| Density [g/cm3] at 20℃ |

8.36 | 8.82 | 8.71 |

| Specific Heat [J/(kg・K)] at 20℃ |

419 | 419 | 419 |

| Thermal Expansion Coefficient [/℃] at 20〜300℃ |

17.8×10-6 | 17.6×10-6 | 17.6×10-6 |

| Modulus of Elasticity [kN/mm2] | 127 | 132 | 127 |

| Modulus of Rigidity [kN/mm2] | 49 | 52 | 49 |

| Poidon's Ratio | 0.3 | 0.3 | 0.3 |

| Magnetic Permeability [μ(μ=1+4πk)] | 1.000042 | 1.000031 | 1.000027 |

| NGK Alloy 25 | NGK Alloy 8 | NGK Alloy 11 | NGK Alloy 7 | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Age Hardenable | Mill hardened | 8-1/2HT | 8-HT | 11-HT | 11-SHC | 7-1/2HT | 7-HT | 7-EHT | |

| Thermal conductivity [W/(m・K)] | 99 | 85 | 298 | 280 | 262 | 221 | 194 | 180 | 176 |

| Electrical conductivity [%IACS] | 24 | 21 | 68 | 64 | 60 | 51 | 45 | 42 | 41 |

| Coil | Thickness | 0.05 - 2.0mm |

|---|---|---|

| Width | max. 200mm | |

| Cut to length | Thickness | 0.05 - 1.0mm |

| Length | max. 1200 mm |

| Diameter | 1 - 120mm |

|---|

| Diameter | in coil | 0.2 - 1.0mm |

|---|---|---|

| on bobbin | 0.05 - 0.15mm |

Click the button below to request a catalog containing technical information

Our products and industrial standards listed on this page are used for the purpose of convenience to indicate our products and their correspondence with the standards. They do not imply that the materials or our testing methods conform to or comply with the standards.