Electrostatic chucks

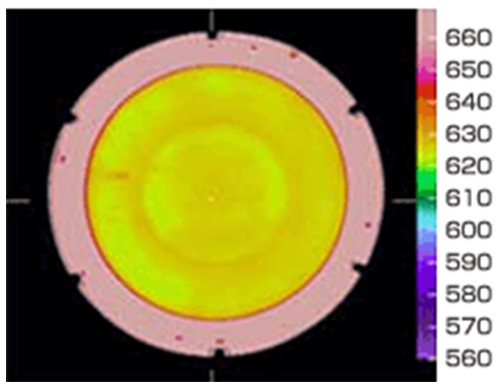

Electrostatic chucks demonstrate high strength, heat conductivity, and heat and shock resistance. Thanks to our proprietary volume resistivity control technologies, these chucks are compatible with a wide range of temperatures.

Products

These heaters have superior corrosion resistance against halogen gas and oxidizing environments.

| Size | Compatible with 200, 300 and 450mm wafer |

|---|---|

| Power supply | 100〜200V×15〜50A |

| Electrode | Ni rods / cables are brazed or screwed to the terminal |

| Material | AlN |

| Aluminum Nitride | ||||

|---|---|---|---|---|

| HA-12 | HA-37/38 | HA-50/51 | ||

| Purity | [%] | 95 | 99 | 99 |

| Density | [g/cc] | 3.3 | 3.3 | 3.3 |

| Volume resistivity | [Ωcm](RT) | >1E+15 | 1E+8〜+13 | >1E+15 |

| Heat conductivity | [W/mK](RT) | 170 | 100 | 80 |

| Coefficient of thermal expansion | (RT) | 5.7(1000℃) | 5.6(1000℃) | 5.6(1000℃) |

| Intensity | [MPa](RT) | >300 | >300 | >250 |

| Young's Modulus | [GPa](RT) | 300 | 300 | 300 |

| Dielectric constant | (13.56MHz、RT) | 8.6 | 8.8 | 8.6 |

Inquiry about Ceramics for Semiconductor Manufacturing

Please apply with the contact form and give us your comments or questions.