Long Rod Insulators

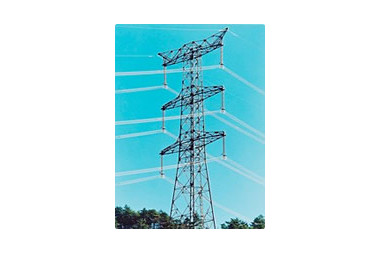

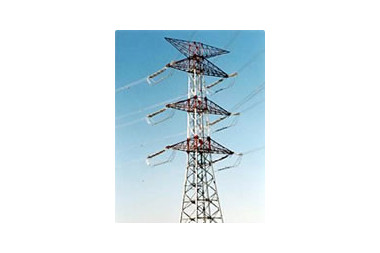

Long rod insulators support transmission lines on steel towers, isolating the lines from the tower. They can be used individually or in configurations of several connected insulators.

Products

Insulators are essential to the safe and stable distribution of electricity generated at power plants. Suspension insulators support transmission lines on steel towers, isolating the lines from the tower. They play a key role in the safe supply of electricity.

Based on the transmission voltage and usage environment, suspension insulators are used in configurations of two or more.

NGK Suspension (Disc) Insulators have been used successfully in more than 100 countries and in particular have a majority in EHV, UHV and HVDC transmission lines.

Available for any voltage and contamination level by changing number of insulators

High reliability is achieved by long-term experience and accumulation of technology.

High strength porcelain insulators require not only higher amount of alumina but also

In addition to ISO 9001 certified,

Hydraulic Pressure Test

Thermal-Mechanical (T&M) performance test as per IEC 60383-1 or ANSI C29.2 is to evaluate long-term reliability of insulators.

As these standards specify minimum requirements only, all NGK insulators have been confirmed to pass modified T&M test.

| Test Method | IEC Pub. 60383-1 | NGK Method |

|---|---|---|

| Load | 60-65% of Specified E&M failing load (24-hour cycle) |

60-65% of Specified E&M failing load (1-hour cycle) |

| Temperature | -30°C to +40°C (24-hour cycle) |

-40°C to +60°C (8-hour cycle) |

| Duration | 4days | 15days |

To exclude poor quality insulators, M&E test results before and after T&M test are:

(R: mean value, s: standard deviation)

Contaminated and wet insulators display a biased leakage current having DC component. This DC component causes electrolytic corrosion and reduction of pin diameter.

NGK developed Zinc Sleeve to prevent pin corrosion.

NGK suspension (disc) insulators meet the requirements and tests of the following standards.

| 60060-1 | High-voltage test techniques, Part 1: General definitions and test requirements |

|---|---|

| 60120 | Dimensions of ball and socket coupling of string insulator units |

| 60305 | Characteristics of insulator units of the cap and pin type |

| 60383-1 | Insulator units - Definitions, test methods and acceptance criteria |

| 60383-2 | Insulator strings - Definitions, test methods and acceptance criteria |

| 60437 | Radio interference test on high-voltage insulators |

| 60471 | Dimensions of clevis and tongue coupling of string insulator units |

| 60507 | Artificial pollution tests on high-voltage insulators to be used on a.c. systems |

| 60575 | Thermal-mechanical performance test |

| 60797 | Residual strength of string insulator units |

| 60815 | Guide for the selection of insulators in respect of polluted conditions |

| 61211 | Puncture testing |

| 61245 | Artificial pollution tests on high-voltage insulators to be used on d.c. systems |

| 61325 | Insulator units for d.c. systems - Definitions, test methods and acceptance criteria |

| C29.1 | Electrical power insulators - test methods |

|---|---|

| C29.2 | Wet-process porcelain and toughened glass - suspension type |

| C411.1 | AC suspension insulators |

|---|

Transmission lines with higher system-voltage carry greater power flow. They serve the role of trunk feeder in the delivery of power. Instability in EHV and UHV line operation may cause great negative impact on the entire power system.

Thus, insulators for EHV and UHV transmission lines require not only endurance against higher electrical and mechanical stress but must also ensure uniformly high quality to maintain the reliability of system operation.

NGK insulators have been the choice for the majority of the world's EHV and UHV transmission projects because of quality and performance. Successful long-term service experience in higher system voltage illustrate the reliability and quality of NGK suspension insulators.

Inquiry about Insulators and power equipment

Please apply with the contact form and give us your comments or questions.