Innovators of Tomorrow

A better world through ceramics

From a ubiquitous and maintenance-free Internet of Things to solutions for the capture, utilisation and storage of carbon, NGK’s ceramics technologies are focused on making our world smarter, cleaner and more sustainable.

There is a seemingly endless buzz about the Internet of Things (IoT), yet the concept suffers from one as yet unaddressed problem: too many IoT devices still depend on human intervention, particularly for battery replacement or charging. Without a maintenance-free power source that works in a range of environments, from remote farm fields to sweltering factories, the promise of a genuinely ubiquitous IoT may never come true.

The need for such a power source is real. There are plenty of places where IoT sensors could be useful, but power cables cannot reach. Primary batteries are an option, but run out of energy and eventually need replacing. Conventional lithium-ion rechargeable batteries have their own issues. At risk of catching fire when overcharged, punctured or exposed to heat, they have to be enclosed in hard protective cases. This makes them bulky and unsuitable for use in awkward locations (the tip of moving robot arms), high-temperature environments (automotive-on-board networks) or for wearables (medical smart patches).

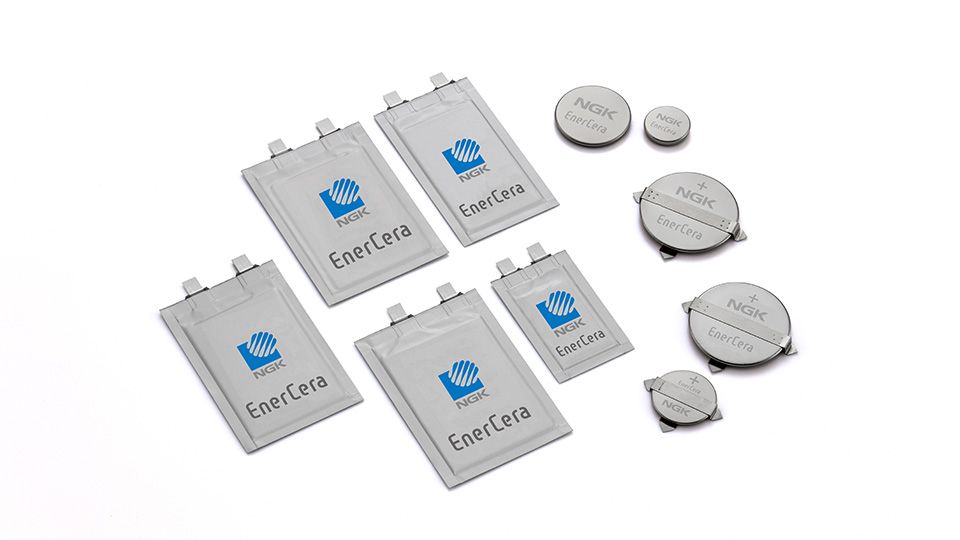

The ideal solution for a ubiquitous, maintenance-free IoT is a long-life rechargeable battery that’s compact, safe and capable of withstanding extremes of hot and cold. Japan-based NGK Insulators, a company which began making insulators in 1919, moved into automobile exhaust gas purification in the 1970s and only started manufacturing batteries in the early 2000s, came out with just such a battery in 2019.

Known as EnerCera* battery, it’s an ultra-compact high-power lithium-ion rechargeable battery that deploys NGK’s deep ceramics know-how (hence the “cera” in the name) to solve the category’s problems. Because EnerCera batteries use semi-solid-state technology, they’re safer than other lithium-ion batteries which depend on organic materials. Because the thinnest version, EnerCera Pouch, is only the size of a small postage stamp, it’s ideal for smart cards and wearables. Because EnerCera Coin, its tougher coin-shaped cousin, can endure temperatures from -40°C to 105°C, it's perfect for heavy-duty outdoor and factory-automation scenarios.

More than 600 companies are testing EnerCera battery samples, while NGK is also working on the development of new applications with multiple outside partners. What particularly excites them is the opportunity to use EnerCera batteries in conjunction with the emergent technologies of energy harvesting and wireless power transfer. Energy harvesting – generating power from solar power or vibrations, for example – produces only milliwatts of micropower, meaning that it’s normally not up to the energy-intensive task of data transmission. But with low leakage and low internal resistance, when the sensors it powers are not sending data, the EnerCera battery can store multiple tiny charges until it has built up the power required for transmission.

Several joint projects combine EnerCera batteries with energy-harvesting and wireless-power-transmission technologies. These include agricultural environment sensors powered by solar power, predictive maintenance sensors on robot arms and smart home sensors, the latter both powered by new forms of wireless power transmission. NGK vice-president Iwao Ohwada, who is responsible for the commercialisation and marketing of EnerCera, has high ambitions for its potential addressable market. “People sometimes refer to IoT as ‘a world of a trillion sensors,’ and with EnerCera that’s the scale of the market we are trying to pioneer and, hopefully, dominate,” he says.

Looking outside. Working with customers

Ohwada’s embrace of outside collaboration reflects a change in NGK’s attitude to innovation, with a shift in emphasis away from a seeds-oriented approach (i.e., ideas generated in-house) to a customer-centric approach that seeks rapid commercialisation through concentrating on real needs. “We can’t be inner-focused anymore,” Ohwada says. “We must think of the market and customer needs from the earliest stage.”

As part of this reorientation, Ohwada was recently put in charge of global business creation at Corporate NV Creation, a new 100-person-strong division charged with creating new products (the NV stands for “new value”) to the tune of a targeted ¥100 billion in annual sales by 2030. The company has also established a dedicated corporate venturing team that is actively on the hunt for outside start-ups for investment.

All these organisational changes flow from “Road to 2050”, NGK’s April 2021 mid to long-term vision. According to this, the company will aim to dramatically boost its output of innovative ceramic-based products in the burgeoning fields of digital society and carbon neutrality. These two fields currently account for 30% of sales, but NGK is targeting 50% of the total by 2030 and 80% by 2050.

On the digital society side, NGK is starting from a strong position. While mass production of EnerCera batteries is only just getting underway, in the last fiscal year the company generated ¥150 billion in digital-related product sales, including high-performance components used in semiconductor manufacturing equipment, bonded wafers for surface acoustic wave (SAW) filters (which select the desired frequencies in mobile devices), and small ceramics packages for electronics.

More solutions for less carbon

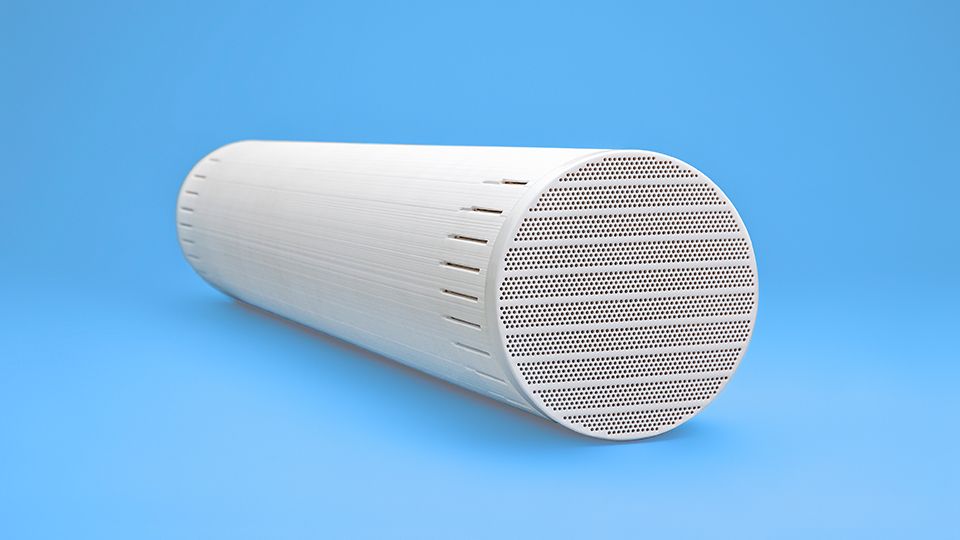

As carbon dioxide in the Earth’s atmosphere reaches record levels, NGK is producing solutions to help capture, utilise and store carbon emitted from human activity. For example, NGK is experimenting with large ceramic membranes with subnanometre-sized pores that act like sieves, separating gases at the molecular level. NGK is also developing CO2 separation membranes for industrial exhaust gases.

On the utilisation side, Ohwada is working on new technologies including a honeycomb reactor that combines captured CO2 with renewable hydrogen to produce methane and synthetic fuels, and solid oxide electrolysis cells (SOEC) that produce syngas, the raw material for methanols and synthetic fuels, via the electrolysis of water and CO2.

Finally, with storage, NGK is testing an enhanced oil recovery (EOR) system that injects CO2 into depleted wells to force the oil out, captures the same CO2 as it re-emerges and then safely reinjects it back into the ground. Ohwada is optimistic that EOR can prevent more CO2 from escaping into the atmosphere in the already carbon-intensive business of fossil fuel extraction.

“To contribute to the eventual goal of carbon neutrality, we intend to establish a presence at every stage of the carbon cycle,” Ohwada says. “We can repurpose our original technologies and global manufacturing facilities to create new products for this challenge. It’s a promising field.”

With NGK on a mission to deploy its unique ceramic technologies to make society both more connected and more sustainable, Ohwada is confident that Corporate NV Creation, is on its way to making the products the future needs—right now.

Finding carbon solutions for a modern world

EnerCera is a trademark of NGK Insulators, Ltd., registered in the United States and other countries.