Ceramic membranes reshape industrial separation

This content was paid for by NGK Insulators and produced in partnership with the Financial Times Commercial department.

Filtration and chemical separation have played a crucial role throughout history, from purifying water with gravel and sand to sieving curds from whey and distilling spirits. Today, these processes are vital to numerous industrial applications, making separation a cornerstone of the material economy.

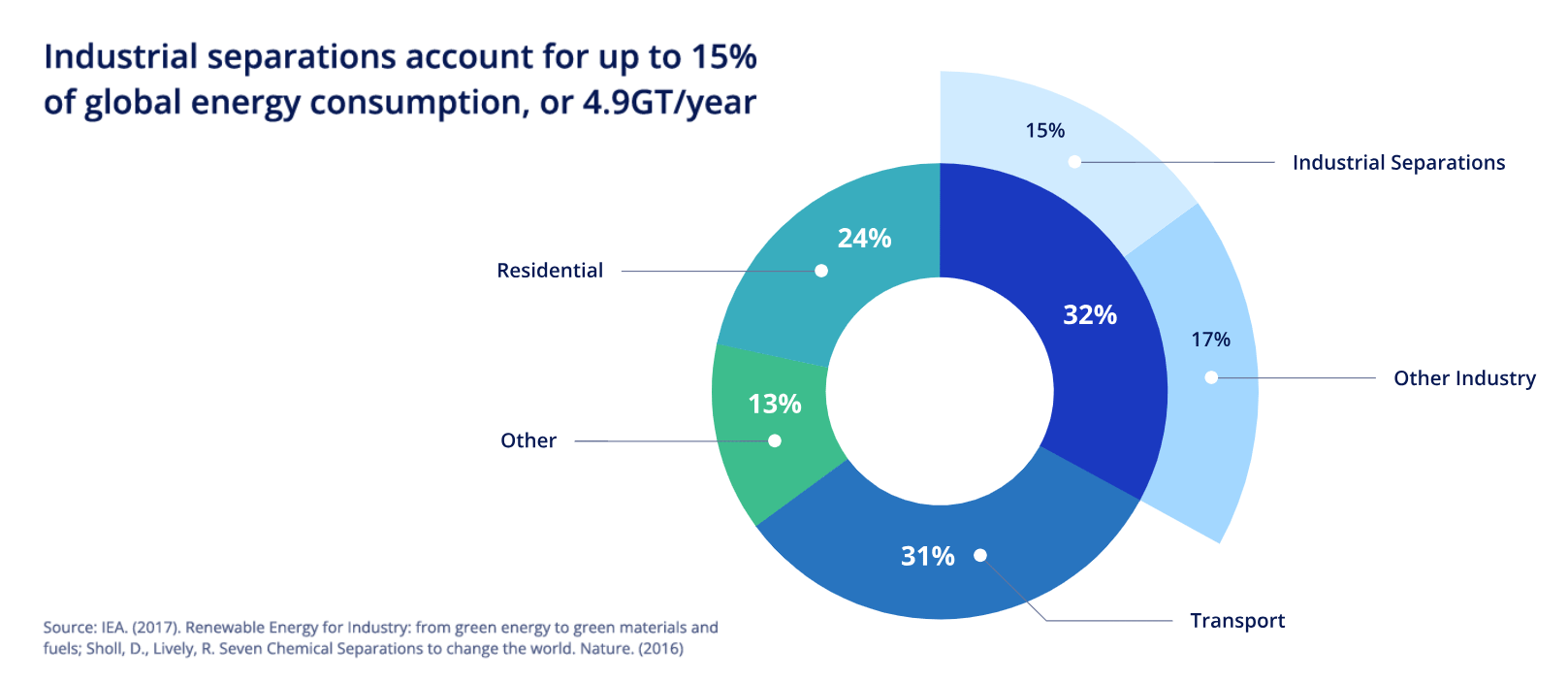

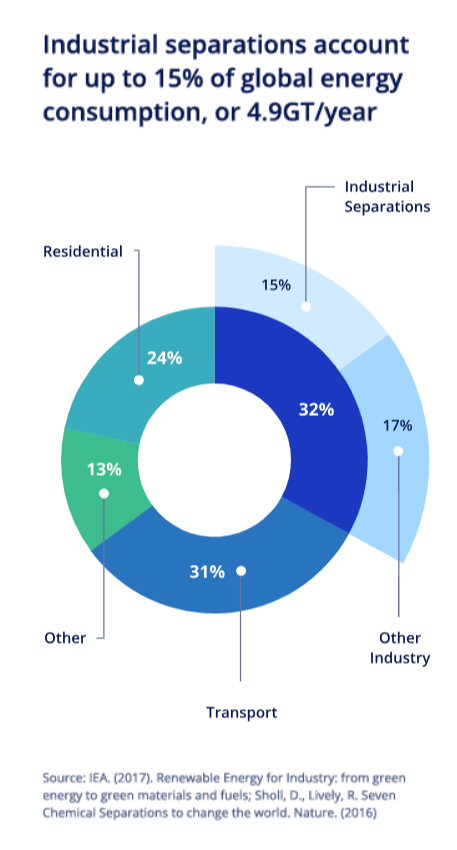

However, they are also highly energy intensive. It’s estimated that up to 15 per cent of global energy consumption is devoted to separation processes such as distillation.

“Almost all commercial chemicals arise from a separation process that could be improved,” write David S. Sholl and Ryan P. Lively in Seven Chemical Separations to Change the World, published in Nature. “Unfortunately, alternatives to distillation, such as separating molecules according to their chemical properties or size, are underdeveloped or expensive to scale up.”1

Businesses and researchers are racing to develop more efficient separation methods.

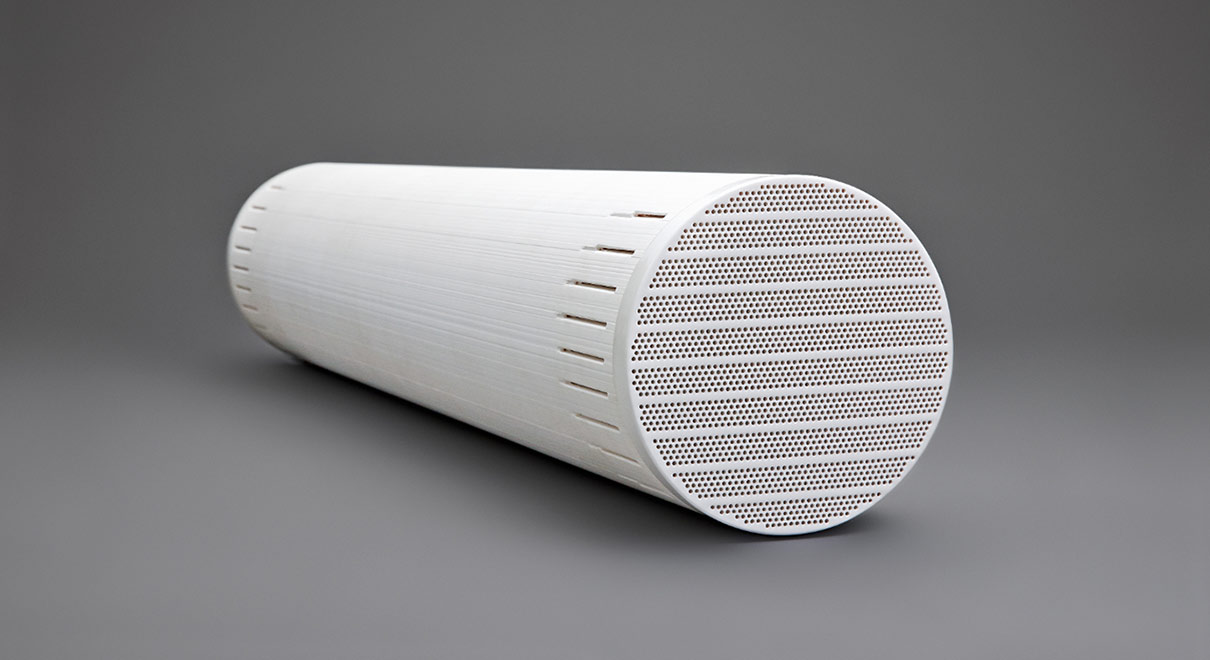

One of these businesses is NGK Group, which has developed a ceramic sub-nano membrane.

The membrane can filter elements as small as hydrogen and nitrogen, thanks to sub-nanometre pores. Its precision is such that it can separate carbon dioxide from methane – molecules that differ in size by just 0.05 nanometres. As a ceramic material, it is highly durable, resistant to heat and corrosion than a polymeric membrane. And it is capable of separating gases, liquids and solids.

These properties give it a wide range of potential applications.

Capturing and reducing carbon emissions

“Although there are other ceramic-based membranes in the market, only NGK can make them of such size and quality with low defect ratios and high throughput,” according to Frank Striebel, director of New Value Business at NGK Europe GmbH. “We have been developing this technology for over 20 years, looking at various applications and fine-tuning them.” This technology has received the GSC (green sustainable chemistry) incentive award in 2020 from the Japan Association for Chemical Innovation.

One of the applications for these membranes furthest along in development is its use in carbon capture and storage (CCS) for enhanced oil recovery (EOR), which involves injecting CO2 into oil wells to extract more crude oil. NGK has been testing the potential of this technology, and based on these results, it hopes to contribute to reducing emissions from existing oil wells serving as a transitional solution while the world shifts away from fossil fuels.

While capturing CO2 emissions at source or already in the air (NGK is also prototyping ceramic technologies for direct air capture systems) is necessary, the sub-nano membrane can offer substantial potential to cut emissions in the commercial production of various chemicals by providing a more energy-efficient alternative to conventional separation processes.

“There’s huge potential to reduce the energy consumption in separation by using membrane separation. In some cases, reductions can be as much as 90 per cent compared to traditional distillation,” says Striebel, quoting a research piece in British scientific journal Nature.2

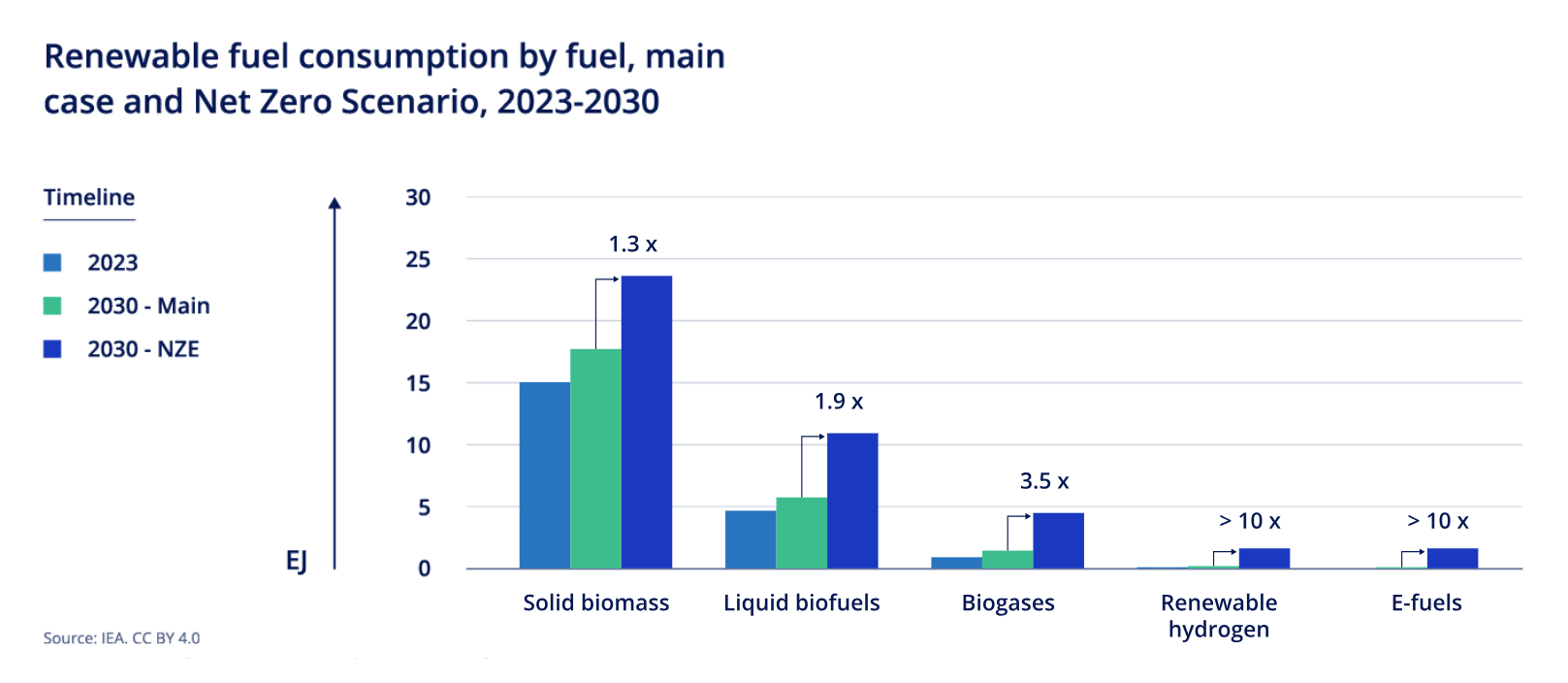

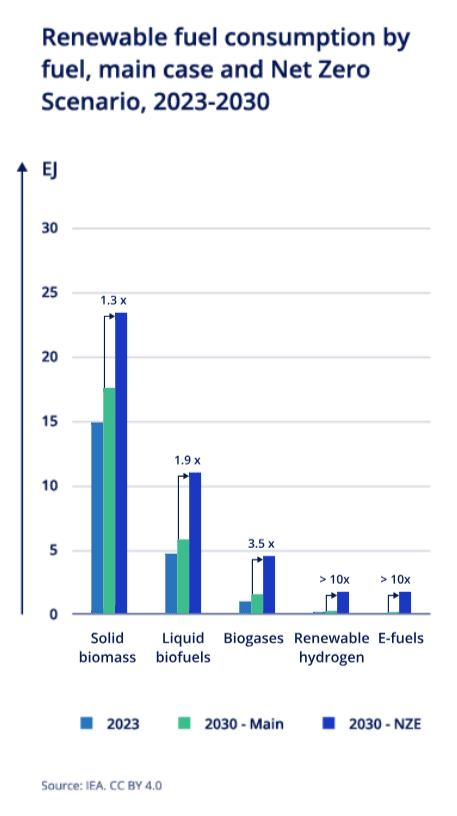

The sub-nano membrane also promises to reduce energy usage, costs and emissions both for the production and transport of various renewable fuels – such as biofuels, biogases, and e-fuels well as hydrogen and ammonia made from renewable sources – needed for hard-to-electrify industries such as shipping and aviation.3

In 2024, NGK announced a collaboration with Mitsubishi Heavy Industries, Ltd. (MHI) to develop membrane dehydration systems for bioethanol, a low-carbon fuel derived from corn and sugarcane, and e-methanol, synthesised using renewable hydrogen. These membrane systems, designed to replace or complement conventional heat-intensive distillation, will be used to separate the final product from water to significantly reduce energy consumption and emissions.

Of course, the company is aware that manufacturing is a hard-to-abate sector, and as such has been also working to reduce emissions from its value chain, including the way products like the sub-nano membrane are produced, used and disposed of at the end of its life cycle As of 2023, NGK Group had reduced annual emissions by 24 per cent compared to a decade ago to 560,000 metric tonnes.

Enabling a hydrogen economy

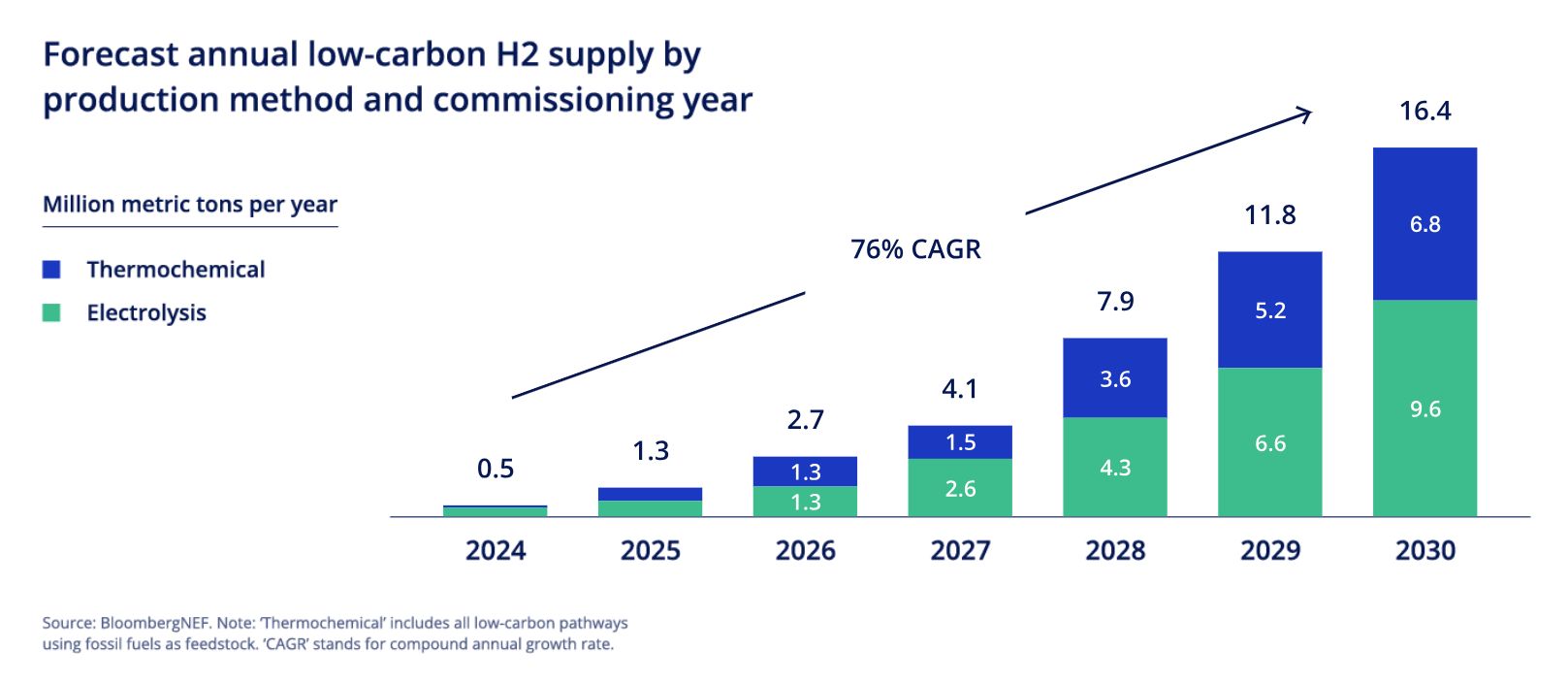

Efficient separation technology can also be important in scaling up hydrogen usage.4

One of the main bottlenecks in hydrogen adoption is the lack of infrastructure connecting regions with abundant, low-cost renewable energy – such as solar-rich areas near the equator – to consumers worldwide. In its pure form, hydrogen must be either liquefied at extremely low temperatures or compressed under high pressure, which expends considerable energy. Additionally, pure hydrogen cannot readily be shipped, piped or stored using existing infrastructure. Developing dedicated hydrogen pipelines, ships and terminals will be costly and time-consuming.5

One solution is to blend hydrogen with natural gas, allowing it to move through existing pipelines.

“After blending hydrogen into natural gas and transporting it to the final destination, the two gases have to be separated out to a well-defined level of purity,” says Striebel.

“The key is to separate hydrogen at the highest possible pressure, as you don’t want to spend a lot of energy recompressing the gas. Here, it is good to have a ceramic membrane, like NGK’s, with very high structural durability that can operate at such high pressures.”

Hydrogen can also be transported as ammonia to destinations not connected by pipelines using existing infrastructure.6 However, at the destination, the hydrogen must be extracted before use.

For destinations not connected by pipelines, such as large coastal cities in Asia, hydrogen can be safely and stably shipped in the form of ammonia in existing vessels and terminals.7 But here too, at destination, the hydrogen must be separated out before use.

In this domain, NGK has partnered with MHI to develop a membrane system for separating hydrogen from ammonia that has been “cracked” into a hydrogen-nitrogen mixture.

“We are working together with MHI in anticipation of the introduction of a hydrogen/ammonia supply chain and the full-scale mass transportation of ammonia,” said Shigeru Kobayashi, president of NGK Insulators, Ltd., addressing investors and industry representatives at a decarbonisation symposium in March 2025.

Partnerships in membrane separation

In February 2025, NGK agreed to acquire Borsig GmbH, a German engineering company specialising in process and membrane technology. Once the acquisition is finalised, the two firms will integrate their membrane technologies and customer networks to advance efficient separation solutions as the world transitions to lower-emission fuels.

This development comes at a critical time for an industry facing rising energy costs.

“Overall, the chemical industry is producing more and has to separate more products, so this means an overall increase in energy requirements,” says Striebel. “As long as energy was cheap and steadily available, they could rely on existing technologies, but now that is changing, and we expect new membrane separation technologies to become increasingly relevant.”

Sources:

1 https://www.nature.com/articles/532435a

2 https://www.nature.com/articles/532435a

3 https://iea.org/reports/renewables-2024/renewable-fuels

https://iea.org/energy-system/low-emission-fuels/biofuels

4 https://www.iea.org/energy-system/low-emission-fuels/hydrogen

5 https://www.oxfordenergy.org/publications/global-trade-of-hydrogen-what-is-the-best-way-to-transfer-hydrogen-over-long-distances

6 https://iea.blob.core.windows.net/assets/3ece5ee4-7537-4992-8ba6-b83c994c3fd4/GlobalHydrogenReview2024.pdf

7 https://iea.blob.core.windows.net/assets/3ece5ee4-7537-4992-8ba6-b83c994c3fd4/GlobalHydrogenReview2024.pdf