Creating new products

Compact SiC Honeycomb Heater to Bring Carbon Neutrality a Step Closer

Overview

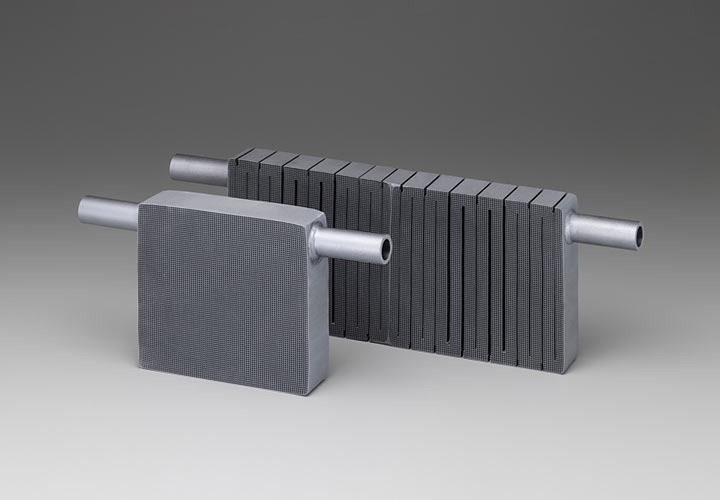

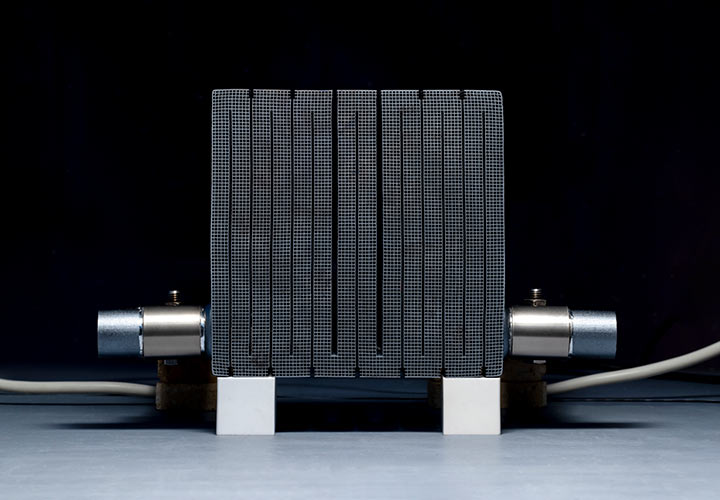

NGK has developed a heater made of silicon carbide (SiC), the SiC Honeycomb Heater, based on the application of our Electrically Heated Catalyst (EHC) technology cultivated in the development of ceramics for purifying automotive exhaust.

Compared to existing ceramic and metal heaters, the SiC Honeycomb Heater offers a larger surface area, allowing it to heat the target gas more efficiently, and provides higher strength, enabling it to withstand exposure to corrosive gases, high temperatures, and high pressure environments.

Furthermore, since the source of the heat is electricity, the heater can help reduce carbon dioxide (CO2) emissions and thereby help achieve carbon neutrality through use of electricity generated from renewable energy sources.

NGK’s Activities toward Electrification for a Carbon Neutral (Decarbonized) Society

NGK supports various efforts to achieve a carbon neutral (decarbonized) society, in which greenhouse gas emissions are reduced to virtually zero.

Keys to achieving carbon neutrality: promoting electrification and adopting green electricity derived from renewable energy sources

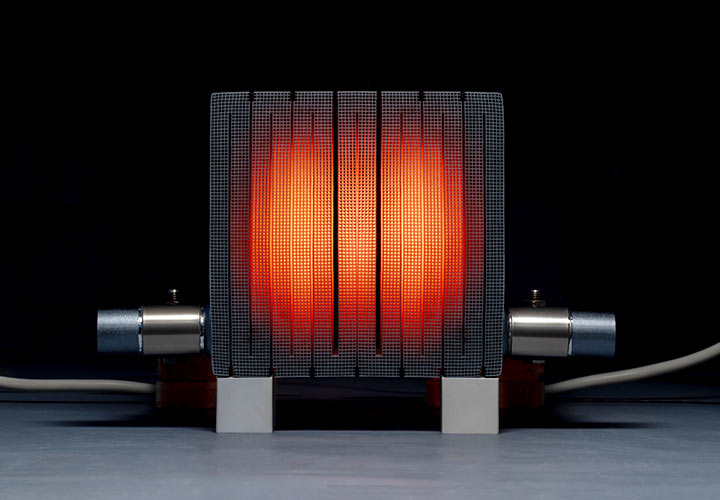

The keys to achieving carbon neutrality are transitioning our energy sources and promoting electrification. We can reduce CO2 emissions by replacing fossil fuels, which emit CO2, with green power derived from renewable energy sources. SiC Honeycomb Heaters, whose power source is electricity, can help reduce environmental loads and achieve carbon neutrality because, in contrast to gas burners that use fossil fuels, they emit no CO, NOx, soot, or other emissions, and do not lose heat through exhaust.

Properties

Contributing to reduced CO2 emissions through highly efficient heating

The honeycomb structure of the SiC Honeycomb Heater provides a larger surface area for heating compared to existing ceramic and metal heaters, which results in a faster and more efficient method of heating. When combined with the use of electricity generated from renewable energy sources, the SiC Honeycomb Heater can reduce CO2 emissions and help reduce environmental loads.

Superior durability to reduce replacement and lower costs

Offering high heat, acid, and corrosion resistance, ceramics have long been used for automotive parts—solid evidence of their capacity to withstand exposure to high-temperature and high-pressure exhaust gases without damage and to withstand engine vibrations. Thus, they will require less frequent replacement and enable cost reduction.

Compact shape contributing to facility downsizing

The compact shape of our SiC Honeycomb Heater allows it to be mounted on piping, making it suitable for a wide range of applications, allowing downsizing of your facilities.

Reduces thermal damage to the heater body and catalyst

The large surface area of the heat-generating part of the honeycomb structure heats gas efficiently, with lower heater body temperatures compared to existing ceramic and metal heaters. This means less thermal damage to the heater body and catalyst.

Adding new value

Catalytic and filter functions can be added to the heater body to customize the heater for your application.

Specification

| Heated material | Gas |

|---|---|

| Temperature of heating | ~1000℃ |

| Material | SiC |

| Shape | Can be designed as rectangular cuboid, cylinder, etc. |

| Dimensions | Up to W150 × D150 × H100 (larger sizes are possible, via bonding) |

SiC material properties

| Material | Si-impregnated SiC | |

|---|---|---|

| Chemical components | SiC[%] | 80 |

| Si[%] | 20 | |

| Physical properties | Apparent porosity[%] | 0 |

| Bulk density | 3.0 | |

| Strength | Bending strength[MPa] | 250 (room temperature~1300℃) |

| Thermal characteristic | Thermal expansion[%] at 1000℃ | 0.45 |

| Thermal conductivity at 350℃[W/(m-k)] | 100.0 | |

| Oxidation resistance[%] (Weight gain rate) |

0.1> | |

| Specific Heat[J/(kg・K)] | 700 | |

Comparison of Surface Area of Heat-generating part

The table below compares the surface area of the heat-generating part of the SiC Honeycomb Heater to those of existing ceramic heaters.

| SiC Honeycomb Heater | Existing Ceramic Heater | |

|---|---|---|

| Preconditions |

□150 x L50mm |

Φ16 x 150mm |

| Surface Area of the Heating Element | 29,500cm2 | 75cm2 |

Potential Applications for the SiC Honeycomb Heater

NGK’s SiC honeycomb heaters have attracted attention in various fields due to their ability to contribute to carbon neutrality based on the use of electric heating method and their durability under the harsh environments found in automotive applications. In addition to the applications listed below, the SiC Honeycomb Heater can be used in other applications by adding a filter, liquid vaporization function, and so on.

Application to Regenerative Thermal Oxidizer (RTO)

Regenerative thermal oxidizers are used to purify exhaust air containing volatile organic compounds (VOCs) emitted from chemical plants and paint factories. The systems currently in wide use are gas burner types, thus replacing them with our SiC Honeycomb Heater, which can make use of green electricity, will enable to reduce CO2 emissions.

Hydrogen production by ammonia (NH3) decomposition (application to catalytic and endothermic reactions)

Ammonia is viewed as a promising energy carrier for transporting and storing hydrogen energy. The method for extracting hydrogen from ammonia (an endothermic reaction) currently being considered uses an external gas burner to heat a reaction tube packed with a catalyst. However, this method can be replaced by a SiC Honeycomb Heater supporting a catalyst that uses green electricity to reduce CO2 emissions. Furthermore, SiC Honeycomb Heaters generate heat themselves, allowing more effective control of temperature differences inside the reaction tube, which in turn will allow the construction of larger reaction tubes and more efficient hydrogen production.

Application to thermal energy storage power generation

Thermal energy storage power generation is a method of storing surplus renewable energy, such as solar power, wind power, in larger quantities and at lower cost compared to storage batteries, which is enabled through conversion into heat and storage using inexpensive materials such as rocks and bricks. Our SiC Honeycomb Heaters can be used in such systems to improve heating efficiency due to the large surface area of the heat-generating part compared to other electric heaters.

Inquiry about Research & Developments

Please apply with the contact form and give us your comments or questions.