Beryllium Copper Strip (Strip, Plate, Rod and Wire forms)

Widely used to form contact springs, these products are available as strips, plates, rods, or wire. Choose from a variety of alloy grades and hardnesses for specific applications.

Featured Articles

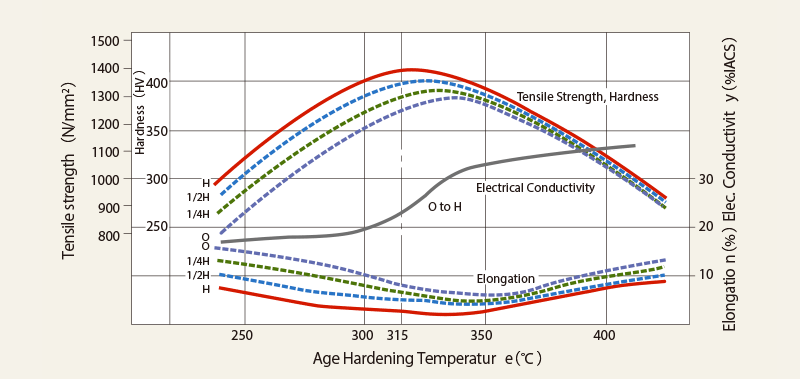

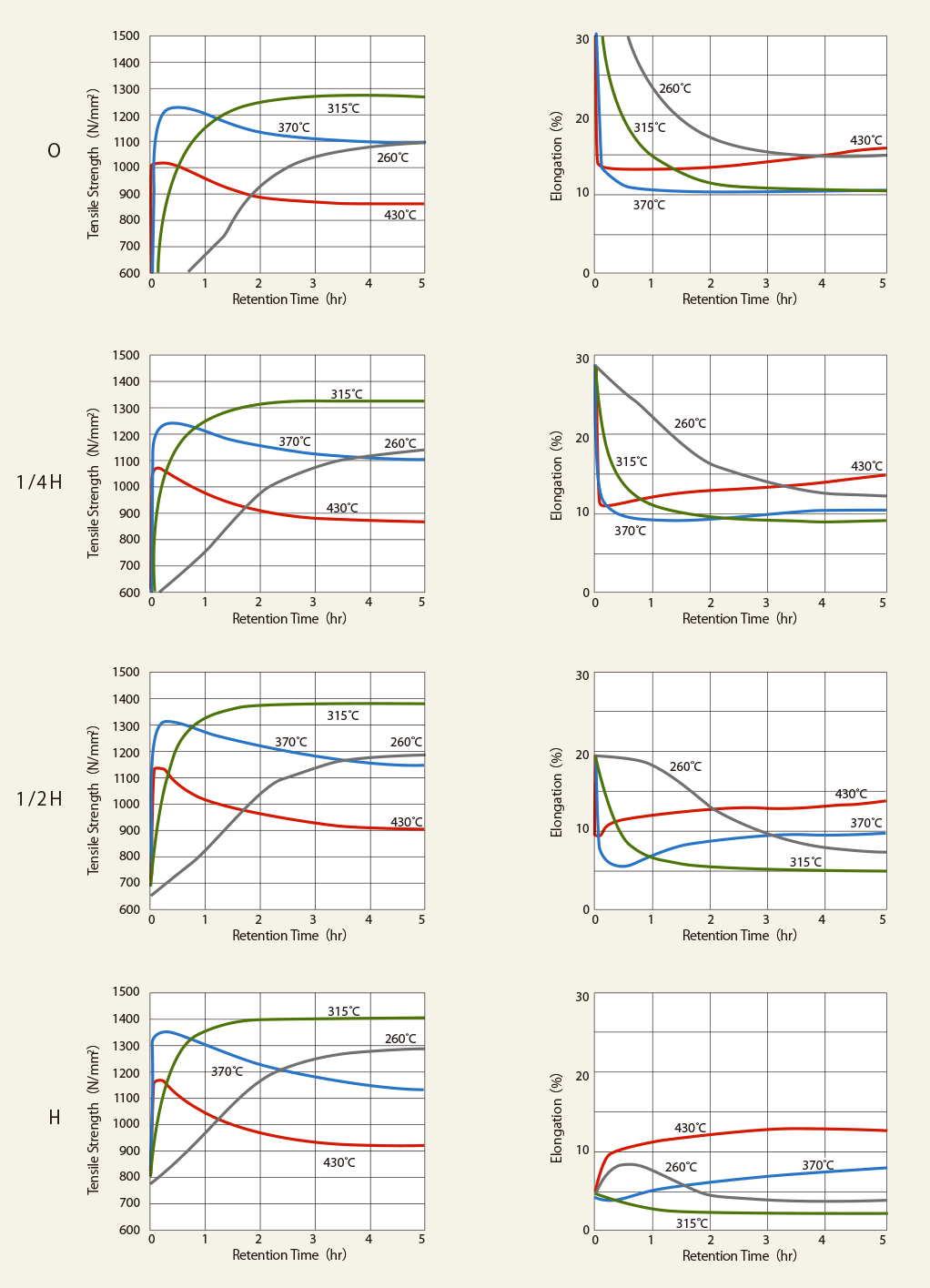

The increase in the mechanical properties of beryllium copper can be controlled through the heat treatment conditions and the cold rolling reduction rates, i.e. temper. This is shown by age hardening curves in Fig. 1 and 2.

Standard heat treatment conditions for beryllium copper alloy 25 age hardenable material are temperature of 315*C and retention time of 2 to 3 hours. The retention time must be counted after the material has reached 315°C. When the volume or weight of parts to be heat-treated in a furnace is relatively large, it is important to ensure that the temperature of the parts is kept at 315t for 2 to 3 hours by directly attached thermocouple. Although the required time to heat up the temperature to 315°C or to cool down to room temperature gives little influence on the properties in case of standard heat treatment conditions, it must be checked carefully when other conditions are applied, e.g. for shorter time or at higher temperature.

Heat treatment of beryllium copper is usually performed in an inert gas atmosphere, such as nitrogen, carbon dioxide or argon. It is not recommended to use air as the atmosphere of the heat treatment for electric components, because an intensive black oxide film will be formed on the surface. In order to keep the uniformity of the temperature in a furnace, it is better to circulate the atmosphere.

The mechanical properties of beryllium copper alloy 25 are drastically increased by age hardening, because beryllium atoms, which were dispersed in copper as a solid solution, are precipitated through various process during age hardening. This results in a shrinkage of approx. 0.15% in length. This is the reason age hardening of stamped parts may cause slight deformation.

The shrinkage varies slightly depending on the temperature of age hardening and the cold reduction prior to stamping. The following methods have proven effective in minimizing distortion.

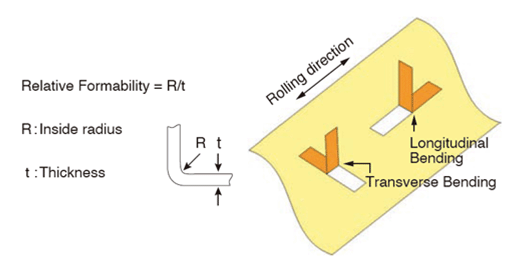

Materials of pressing dies for Beryllium Copper Alloys may be the same as those for other Copper Alloys. However, pressing oil must be chosen carefully. In particular, oil of high chlorine or sulfur content should be avoided because such oil may cause discoloration, or may affect plating or soldering. The normal die materials can also be used for mill-harden materials. However, super-hard alloys are often used when a large number of parts are punched, or when the accuracy of punching or the life of the die must be improved. See Tables 4 to 6 for bend radii (R) for bending. The pressing of Alloy 25 must be performed before age-hardening treatment. These materials are very difficult to bend after age-hardening treatment. Although they can be punched into simple shaped products, the life of dies are shortened.

Since mill-harden Alloy 25, and alloys 11, 10, and 7 after pressing can be used as parts as they are, age-hardening treatment is not required.

| Alloy | Type | Temper | R/t | Typical R/t in thickness 0.15mm | ||

|---|---|---|---|---|---|---|

| Long. | Trans. | Long. | Trans. | |||

| 25 | AH | O | 0.0 | 0.0 | 0.0 | 0.0 |

| 1/4H | 1.0 | 2.0 | 0.0 | 0.0 | ||

| 1/2H | 3.0 | 4.5 | 0.0 | 0.0 | ||

| H | - | - | 0.0 | 1.7 | ||

| MH | OM | 0.8 | 2.0 | 0.0 | 0.6 | |

| 1/4HM | 1.0 | 3.0 | 0.3 | 1.0 | ||

| 1/2HM | 2.0 | 4.0 | 0.6 | 2.7 | ||

| HM | 3.0 | 6.0 | 1.0 | 4.0 | ||

| XHM | 4.0 | - | 3.0 | - | ||

| XHMS | 6.0 | - | 4.0 | - | ||

| MH TypeB | OMB | 0.8 | 0.8 | 0.0 | 0.0 | |

| 1/4HMB | 1.0 | 1.0 | 0.0 | 0.0 | ||

| 1/2HMB | 1.3 | 1.3 | 0.0 | 0.0 | ||

| HMB | 2.5 | 2.5 | 0.6 | 0.6 | ||

| XHMB | 3.4 | 3.8 | 1.7 | 1.7 | ||

| XHMSB | 4.1 | 6.0 | 3.5 | 6.0 | ||

| MH TypeS | HM-TypeS | 1.5 | 1.5 | 0.0 | 0.0 | |

| XHM-TypeS | 2.5 | 2.5 | 1.0 | 1.0 | ||

| Alloy | Temper | R/t | Typical R/t in thickness 0.15mm | ||

|---|---|---|---|---|---|

| Long. | Trans. | Long. | Trans. | ||

| 8 | HT | 1.0 | 1.0 | 0.0 | 0.0 |

| 11 | HT | 2.0 | 2.0 | 0.0 | 0.0 |

| Alloy | Temper | R/t | Typical R/t in thickness 0.15mm | ||

|---|---|---|---|---|---|

| Long. | Trans. | Long. | Trans. | ||

| 7 | 1/2HT | 0.0 | 0.0 | 0.0 | 0.0 |

| HT | 1.5 | 1.5 | 0.0 | 0.0 | |

| EHT | 2.0 | 1.5 | 0.3 | 0.0 | |

Beryllium copper can be joined by soft soldering, silver brazing, resistance welding, TIG and MIG welding like many other metals.

Soft soldering can be performed at a relatively low temperature between approximately 200 and 350°C for a short period of time without adversely affecting the mechanical properties of materials. Since silver brazing is performed at a relatively high temperature of 600 to 800°C, Beryllium Copper is softened. However, hardness is considerably recovered by additional heat treatment at 315°C for 2 to 3 hours because the metal structure is little changed. Therefore, it is recommendable to perform heat treatment after silver brazing. In either soft soldering or silver brazing, the parts should be free from traces of oil and discoloration. Flux must be removed thoroughly by washing because certain types of flux cause corrosion.

Spot welding of sheet materials is commonly used as the resistance welding of Beryllium Copper Alloys. Beryllium Copper Alloys 25 and 165 can be spot welded without any problem. However, since Beryllium Alloy 11 has high electric conductivity, optimum conditions must be found for the shape of projections, the material of electrodes, and the control of electrodes. In the spot welding of Beryllium Copper Alloys, the best result is achieved when a large amount of heat is generated by momentarily discharging direct current a capacitor, or by supplying a pulse of alternating current. Since Beryllium Alloy 11 has high electric conductivity, an electrode having at least a conductivity of IACS75% is required. Usually, chromium copper or zirconium copper is used, but aluminum dispersed copper is also preferred because of its high strength at high temperatures.

Beryllium copper alloys tend to form oxide film on the surface during heat treatment.The oxide film must be removed when further processing such as plating and soldering is necessary. Typical cleaning methods are as follows:

for loose parts, dip them into a 20% solution of sulfuric acid heated up between 50°C to 90°C. The oxide film will be removed in a few minutes. When time allows, the parts can be immersed in the solution at room temperature over night. Since oxide film generated by burnt oil or grease cannot be removed by acid cleaning, degreasing before age hardening is required.

Any residual oil or grease on the surface of beryllium copper may cause the discoloration on the surface or may give an adverse effect on down stream processes such as heat treatment, plating, soldering and welding. When stamping oil is used, thorough degreasing is required after stamping. If the stamping oil contains high chlorine or sulfur, the method of degreasing should be carefully determined, or the use of such oil should be avoided.

Benzotriazol (C6H4N2-NH) is generally used for preventing the discoloration of copper alloys caused by the air. It forms cupric benzotriazol (C6H4N3)2Cu on the surface of copper alloys, which is insoluble in water or other solvents. It will not cause any adverse effect on normal pretreatment for plating or age hardening, because it will be sublimated at 100°C.

Our products and industrial standards listed on this page are used for the purpose of convenience to indicate our products and their correspondence with the standards. They do not imply that the materials or our testing methods conform to or comply with the standards.