Beryllium Copper Strip (Strip, Plate, Rod and Wire forms)

Widely used to form contact springs, these products are available as strips, plates, rods, or wire. Choose from a variety of alloy grades and hardnesses for specific applications.

Featured Articles

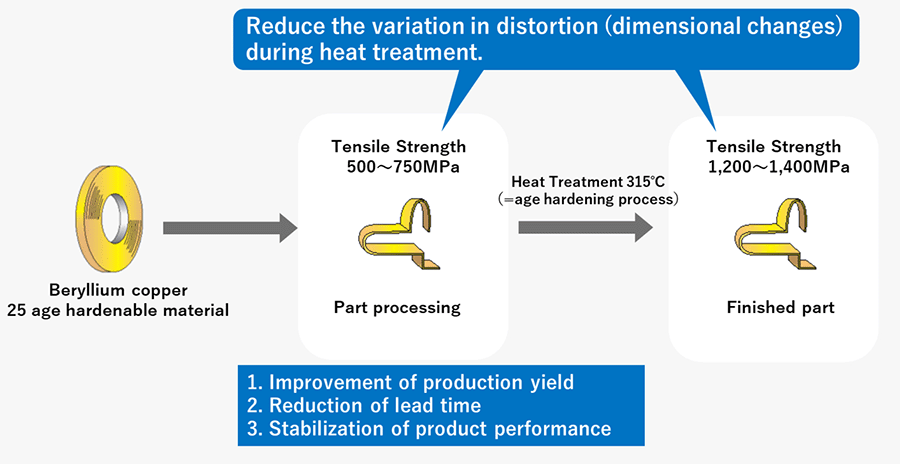

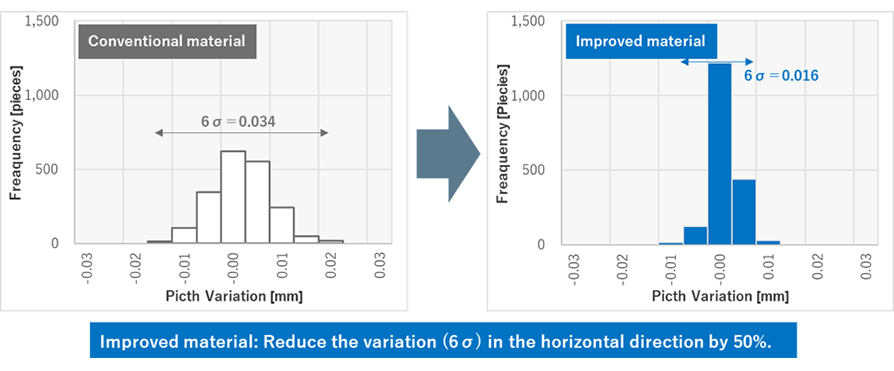

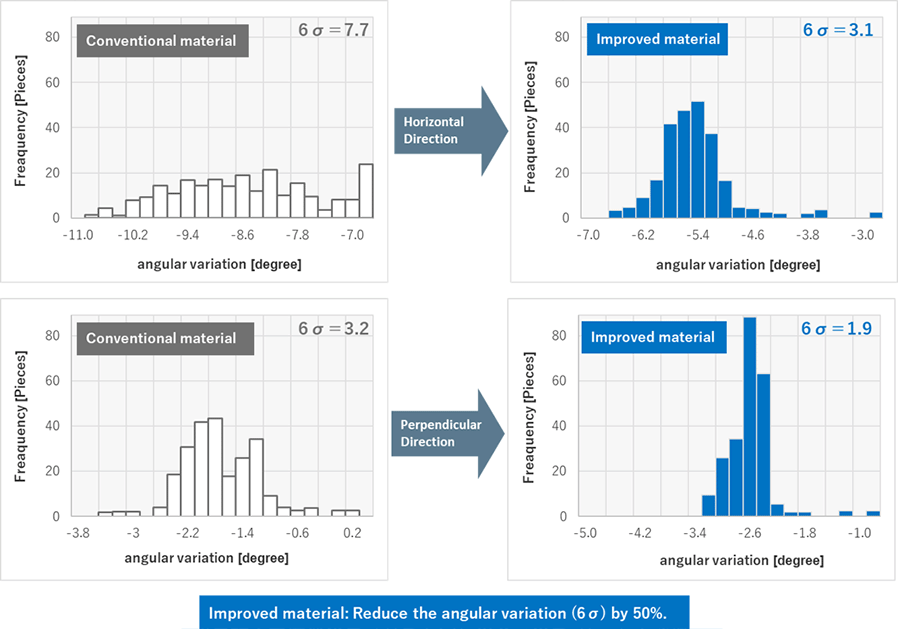

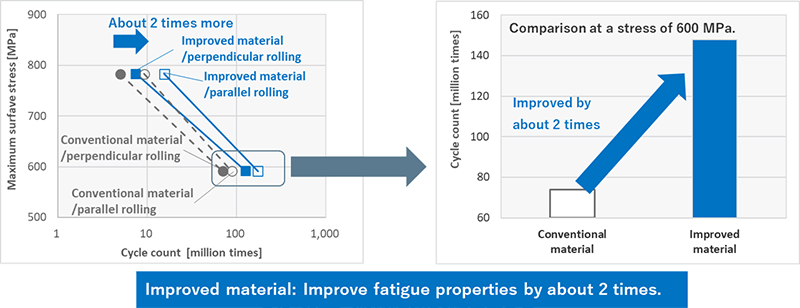

This is a new material developed by NGK through special processes for beryllium copper age hardenable material to reduce distortion during heat treatment and improve fatigue strength.

The improved material enables your product to improve manufacturing yield, shorten lead time and stabilize performance because of less distortion during age hardening process.

| Advantage | Benefit |

|---|---|

|

|

Please feel free to ask us for trial sample.

*The manufacturing upper limit of the improved material is t0.60mm. (Available up to 0.6mm thick)

| Designation4) | Tensile Strength1) (N/mm2) | 0.2%Yield Strength1) (N/mm2) | Elongation1)(%) | Vickers Hardness1)(HV) | Electrical Conductivity2)(%IACS) |

Precipitation-Heat-Treatment (℃×hr) |

|

|---|---|---|---|---|---|---|---|

|

Standard material |

C1720P-O C1720R-O |

410-540 | — | min. 35 | 90-160 | — | — |

|

C1720P-OT C1720R-OT |

1100-13803) | min. 960 | min. 3 | 350-400 | min. 22 | 3hr.at 315℃ | |

|

C1720P-1/4H C1720R-1/4H |

510-620 | — | min. 10 | 145-220 | — | — | |

|

C1720P-1/4HT C1720R-1/4HT |

1180-14003) | min. 1030 | min. 2 | 360-430 | min. 22 | 2.5hr.at 315℃ | |

|

C1720P-1/2H C1720R-1/2H |

590-695 | — | min. 5 | 180-240 | — | — | |

|

C1720P-1/2HT C1720R-1/2HT |

1240-14403) | min. 1100 | min. 2 | 370-440 | min. 22 | 2hr.at 315℃ | |

|

C1720P-H C1720R-H |

685-835 | — | min. 2 | 210-270 | — | — | |

|

C1720P-HT C1720R-HT |

1270-14803) | min. 1140 | min. 1 | 380-450 | min. 22 | 2hr.at 315℃ | |

|

Improved material |

C1720P-OK C1720R-OK |

410-540 | — | min. 35 | 90-160 | — | — |

|

C1720P-OKT C1720R-OKT |

1100-13803) | min. 960 | min. 3 | 350-400 | min. 22 | 3hr.at 315℃ | |

|

C1720P-1/4HK C1720R-1/4HK |

510-620 | — | min. 10 | 145-220 | — | — | |

|

C1720P-1/4HKT C1720R-1/4HKT |

1180-14003) | min. 1030 | min. 2 | 360-430 | min. 22 | 2.5hr.at 315℃ | |

|

C1720P-1/2HK C1720R-1/2HK |

590-695 | — | min. 5 | 180-240 | — | — | |

|

C1720P-1/2HKT C1720R-1/2HKT |

1240-14403) | min. 1100 | min. 2 | 370-440 | min. 22 | 2hr.at 315℃ | |

|

C1720P-HK C1720R-HK |

685-835 | — | min. 2 | 210-270 | — | — | |

|

C1720P-HKT C1720R-HKT |

1270-14803) | min. 1140 | min. 1 | 380-450 | min. 22 | 2hr.at 315℃ |

1) Values are applicable to thickness 0.1mm and over.

2) Electrical conductivity is for design guidance only.

3) The upper limits of tensile strength after age hardening are for design guidance only.

4) P and R in column "Designation" represent "strip cut to length" and "strip in coils".

Our products and industrial standards listed on this page are used for the purpose of convenience to indicate our products and their correspondence with the standards. They do not imply that the materials or our testing methods conform to or comply with the standards.

Inquiry about Special Metals

Sales & Marketing Division