Featured Articles

Applications for Separation Membranes (Sub-nano Ceramic Membranes) that Contribute to Carbon Neutrality

Membrane separation processes contributing to carbon neutrality

Sub-nano ceramic membranes enable energy-efficient separation processes, thereby contributing to carbon neutrality. For example, conventional distillation methods for separating water from organic solvents require significant energy to heat the solvent. Methods based on sub-nano ceramic membranes require less energy and save energy in the separation process. Other applications include gas separation technologies for CO2, H2, N2, CH4, and other liquids and gases. This technology is expected to be also useful in the applications listed below.

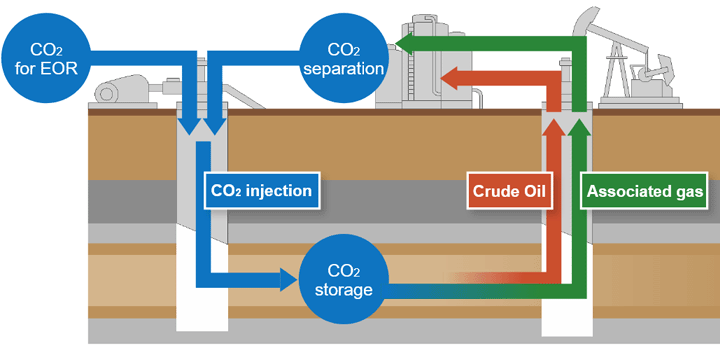

(1) CO2-EOR (Carbon Dioxide Enhanced Oil Recovery)

CO2-EOR technology enhances crude oil recovery rates by injecting CO2 into an oil layer below the ground to lower the viscosity of the residual oil and increase its fluidity. Since some of the CO2 injected into the oil layer remains fixed underground, this technology has drawn attention as a potential CCS (Carbon Capture and Storage) method for reducing greenhouse gas emissions while producing crude oil at the same time. Sub-nano ceramic membranes efficiently capture and recycle CO2 even in environments of high pressure and high CO2 concentrations, thus offers a cost effective solution for CO2-EOR projects and helps strike a balance between the need to secure energy resources essential to society and the need to curb global warming.

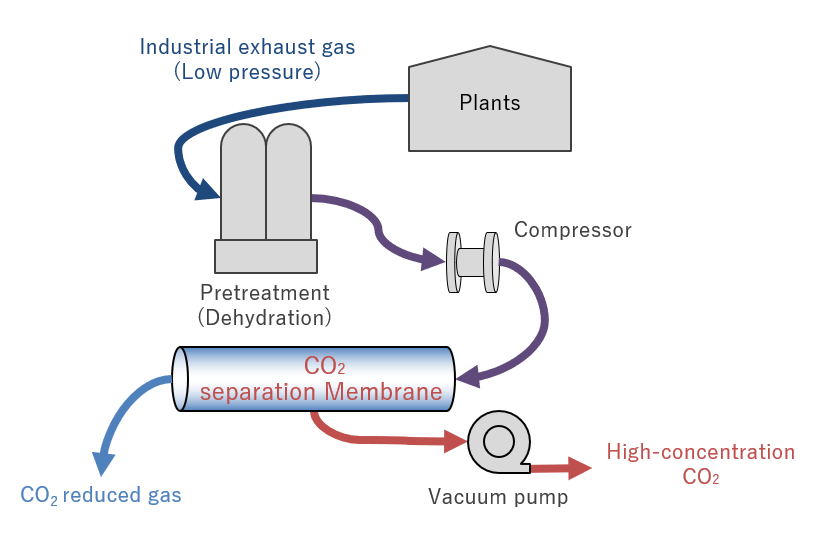

(2) CO2 separation from industrial exhaust gas

As the pursuit of carbon neutrality intensifies, the importance of technologies for collecting CO2 in industrial exhaust gas from factories and other facilities will continue to grow. However, the gas pressure of industrial exhaust gas tends to be lower than gas pressures in other applications, and so designing an optimal process characterized by reduced pressure loss and high permeability will be crucial to the development of such technologies. That is why NGK is also focused on developing CO2 separation membranes for industrial exhaust gases that can be used to separate CO2 contained in industrial exhaust gases from factories and other facilities.

- * Separation processes using sub-nano ceramic membranes require pressure differences exceeding a certain minimum between the feed side and permeate side.

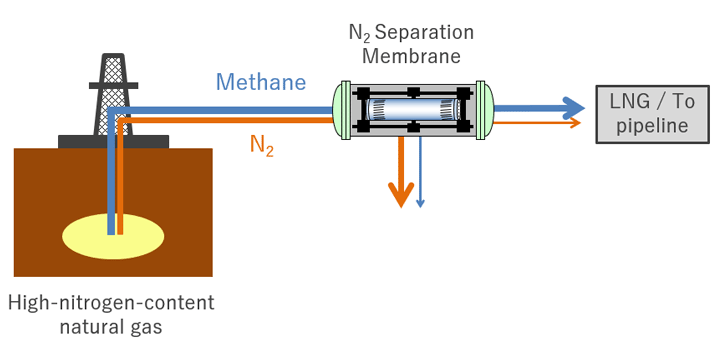

(3) N2 separation from natural gas

Natural gas from gas fields distributed widely around the world may contain nitrogen (N2) as an impurity. This N2 must be removed to obtain high-quality natural gas suitable for pipeline transportation and liquefied natural gas (LNG) production. The current widespread method of N2 removal, the cryogenic separation method, requires large-scale equipment and significant energy. In contrast, NGK’s sub-nano ceramic membranes require neither, making it possible to realize compact N2 removal processes with low environmental impact. NGK is committed to helping to realize a low-carbon society by promoting the use of natural gas, which has a lower environmental impact than coal or oil.

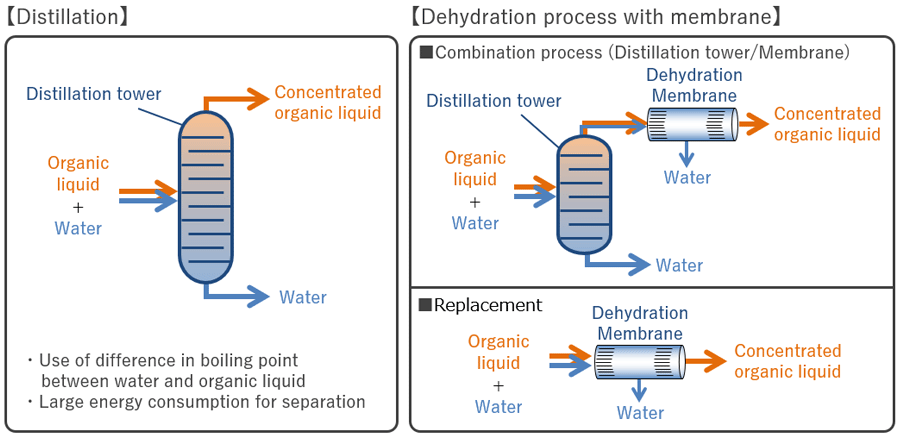

(4) H2O separation from hydrous organic liquids

Sub-nano ceramic membranes can also be applied to dehydration processes. Currently, organic liquid dehydration is typically carried out by the distillation method, which relies on a difference in boiling point to separate water from organic solvents, so this process requires large amounts of energy for heating. Separation using NGK’s sub-nano ceramic membranes require less energy than the distillation method and thereby contributes to CO2 reduction and carbon neutrality. It is especially effective in the dehydration of azeotropes whose components have boiling points similar to that of the mixture and for the dehydration of substances with large reflux ratios in the distillation process.

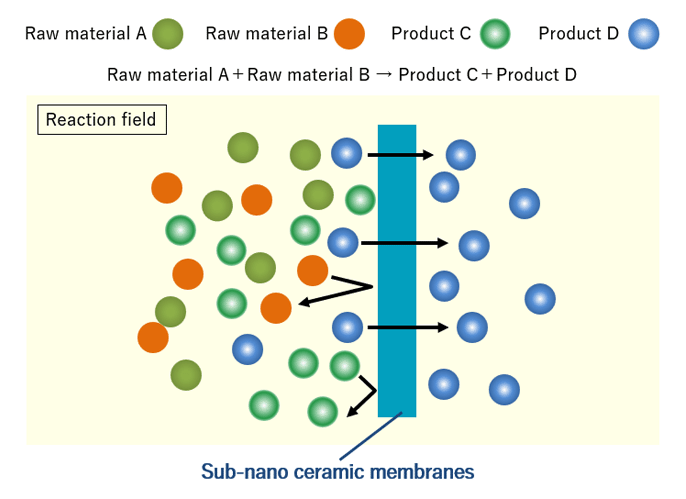

(5) Application of sub-nano ceramic membranes in membrane reactors

Membrane reactors are a promising new area of applications for sub-nano ceramic membranes. For processes like fuel synthesis from CO2 in which chemical reactions are typically difficult to accelerate, extracting a portion of the reaction product from the reaction fields can prevent the reaction from reaching chemical equilibrium and accelerate the reaction. However, these chemical processes often involve high temperature and pressure, requiring significant amounts of energy. In contrast, membrane reactors using sub-nano ceramic membranes require less energy to extract the products from the reaction field, which helps reduce CO2 emissions and achieve carbon neutrality.

Related Products

NGK offers a wide range of ceramic filter products with different pore sizes.

Featured Articles

Inquiry about Research & Developments

Please apply with the contact form and give us your comments or questions.