Featured Articles

Applications and Separation Properties of Sub-nano Ceramic Membranes

Types and applications of sub-nano ceramic membrane

Below are the types of NGK sub-nano ceramic membranes currently available, and some examples of their applications. Examples of systems incorporating these membranes are introduced in 1)– 3). These are under development.

| Applications | Separation target | |

|---|---|---|

| Gas separation |

・CO2 recovery from associated gas of CO2-EOR ・CO2 separation from natural gas 1) ・Biogas purification 3) |

CO2/CH4 |

| ・He recovery from natural gas | He/CH4 | |

| ・H2 separation for chemical process ・H2 recovery from reaction gas |

H2/Methylcyclohexane H2/Ethane H2/CH4 H2/N2 |

|

|

・N2 separation from natural gas 2) ・CH4 recovery from LNG boiled off gas |

N2/CH4 | |

| ・CO2 recovery from industrial exhaust gas | CO2/N2 | |

| Dehydration |

・Dehydration from organic liquid ・Dehydration in the ester synthesis process ・Recycling of used organic liquid ・Dehydration in membrane reactor |

H2O/Alcohol H2O/Ketone H2O/Ether H2O/Ester H2O/Aromatic |

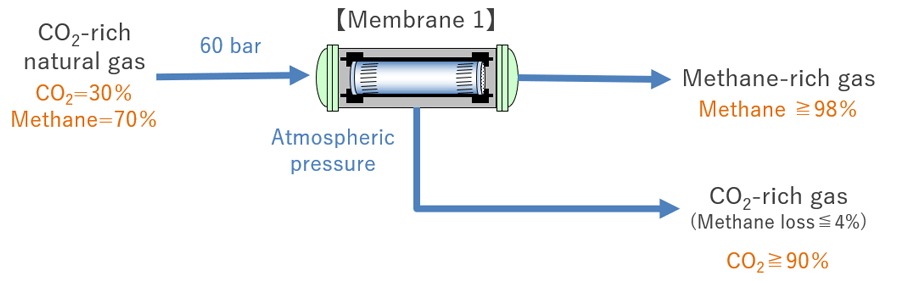

1) CO2 separation from natural gas

High-purity CH4 (methane) and CO2 can be obtained while suppressing methane loss by separating and removing the CO2 contained as an impurity in natural gas, through use of a sub-nano ceramic membrane in a one-stage membrane system.

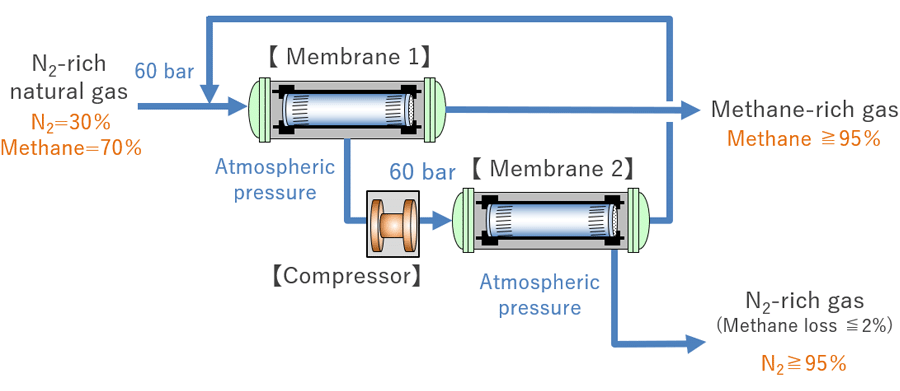

2) N2 separation from natural gas

N2 contained as an impurity in natural gas can be separated and removed using a sub-nano ceramic membrane. A two-stage membrane system makes it possible to obtain high-purity methane while suppressing methane loss.

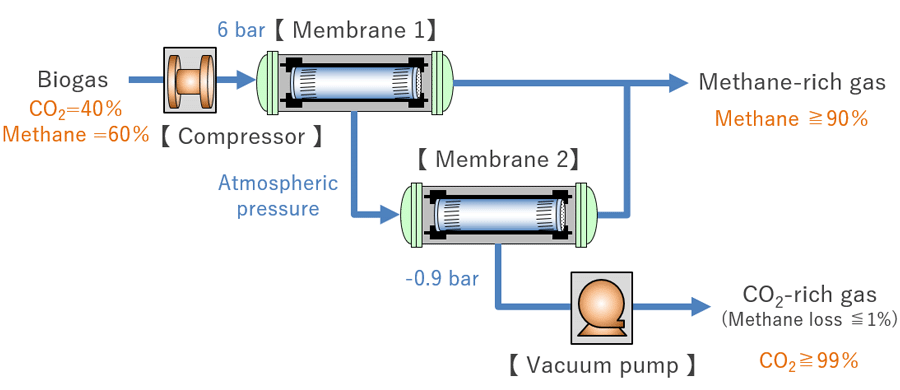

3) Biogas Purification

The biogas produced from biomass contains CH4 (methane) and CO2. Sub-nano ceramic membrane can also be used to separate and remove CO2 from biogas. A two-stage membrane system makes it possible to obtain high-purity methane and CO2.

Separation properties of sub-nano ceramic membranes

Separation properties for a gas mixture using sub-nano ceramic membranes

| Composition of gas mixture [mol%] |

Test conditions | Performance | ||

|---|---|---|---|---|

| Pressure of feed gas [MPaG] |

Temperature of feed gas [℃] |

Composition of permeate gas [mol%] |

Separation coefficient※ [-] |

|

| CO2 : CH4 = 50 : 50 | 0.3 | 25 | CO2 > 99 | >160 |

| H2 : CH4 = 60 : 40 | 0.4 | 25 | H2 > 99 | >100 |

| N2 : CH4 = 50 : 50 | 0.4 | 25 | N2 > 96 | >30 |

Dehydration performance from hydrous organic liquid using sub-nano ceramic membranes

| Separation method | Organic liquid | Test conditions | Dehydration performance | ||||

|---|---|---|---|---|---|---|---|

| Organic liquid concentration of feed liquid [wt%] |

Temperature of feed liquid [℃] |

Vacuum pressure at permeate side [torr] |

Water permeation rate [kg/m2h] |

Organic liquid concentration of permeate liquid [wt%] |

|||

| Pervaporation (PV) |

Alcohol | Isopropanol | 90 | 70 | 50 | 3 | <1 |

| n-Butanol | 90 | 70 | 50 | 4.5 | <1 | ||

| Ketone | Acetone | 90 | 45 | 10 | 1 | <2 | |

| Ether | Tetrahydrofuran | 90 | 50 | 10 | 4 | <1 | |

| Ester | Ethyl acetate | 97 | 70 | 50 | 6 | <1 | |

| Organic acid | Acetic acid | 30 | 90 | 200 | 9.5 | <1 | |

| Vapor permeation (VP) |

Alcohol | Ethanol | 90 | 105 | 10 | 6 | <1 |

Related Products

NGK offers a wide range of ceramic filter products with different pore sizes.

Featured Articles

Inquiry about Research & Developments

Please apply with the contact form and give us your comments or questions.