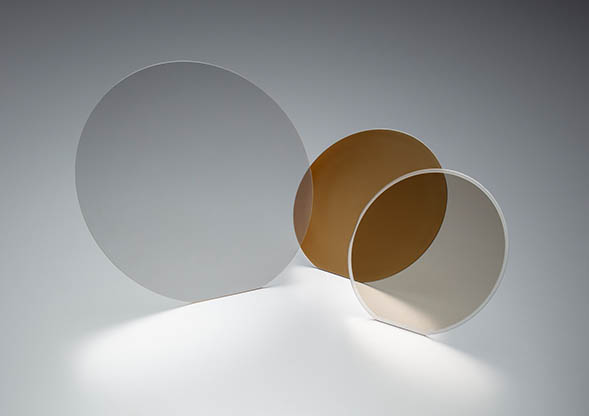

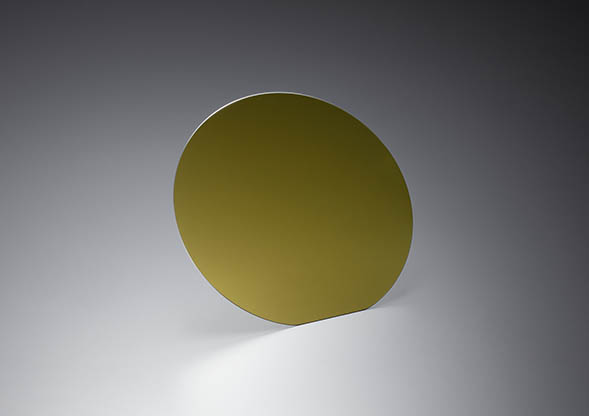

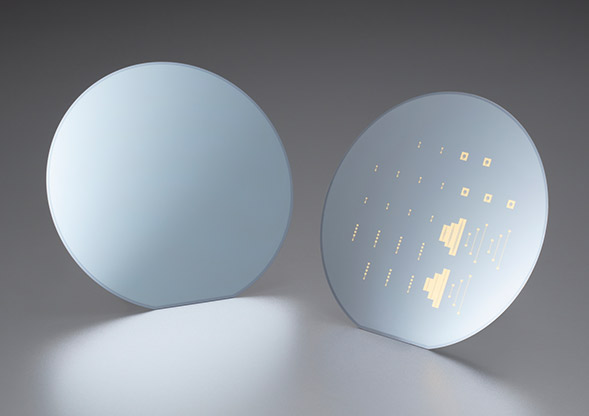

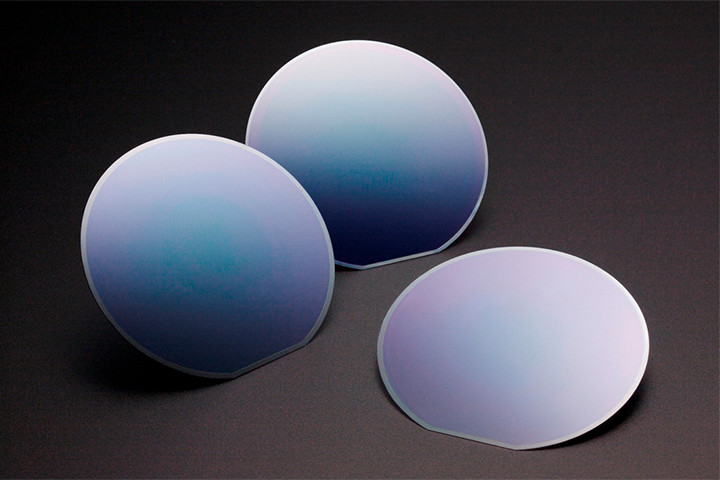

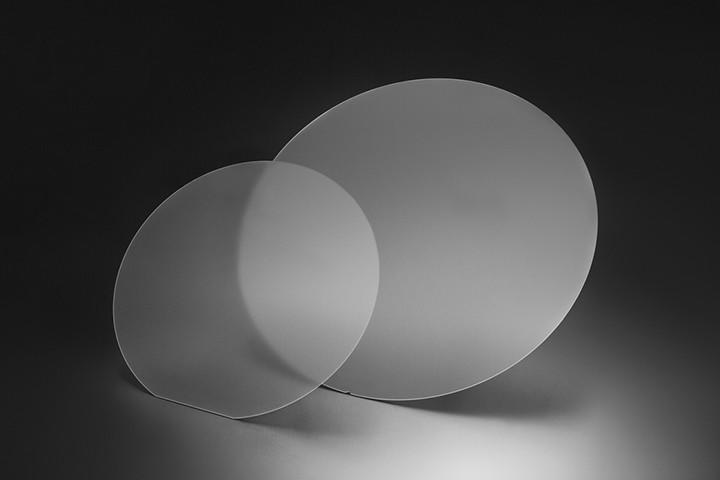

Gallium Nitride (GaN) Wafer

Created using NGK’s proprietary liquid phase crystal growth method, the GaN wafer exhibits low dislocation density across the entire wafer surface. We have developed two different types of GaN wafers: a semi-insulating type for high frequency devices for 5G and 6G wireless base stations; and a conductive type for the power devices incorporated into EVs, power control units, and optical devices used as light sources for projectors.