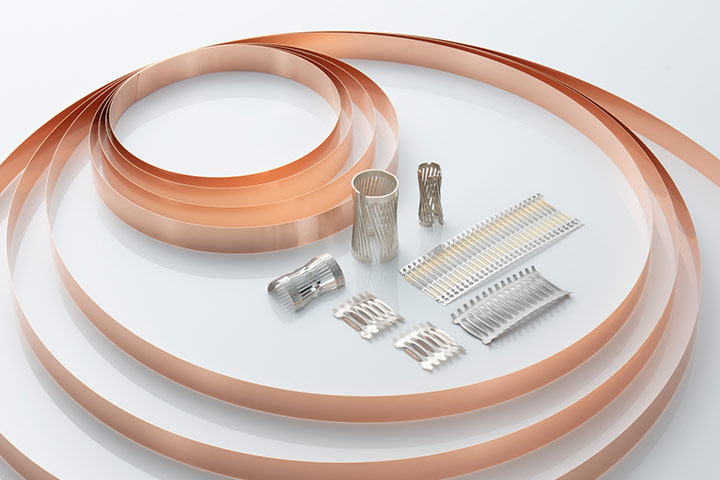

Beryllium Copper Strip (Strip, Plate, Rod and Wire forms)

Widely used to form contact springs, these products are available as strips, plates, rods, or wire. Choose from a variety of alloy grades and hardnesses for specific applications.

Products

In 1958, NGK became Japan's first company to succeed in the industrial production of beryllium copper under the industrialization research program under the Ministry of International Trade and Industry (MITI). We operate production and sales bases across Japan, where NGK has the leading market share, as well as in the U.S. and Europe, enabling the supply of beryllium copper to meet the needs of the global market.

An indispensable material in many industrial fields, NGK beryllium copper is produced using superior production technology under rigorous quality control conditions.

Copper is pliant, easily workable, electrically and thermally conductive, and corrosion resistant. This versatile metal has a long history in uses such as coins, electric wire, and construction materials. A small amount of beryllium is added to copper to produce alloys that combine copper's key properties with high strength and elasticity rivaling special steels.

Beryllium copper is now found in vehicles, mobile phones, computers, and communication devices, where it is used as a conductive spring material that enhances reliability and helps shrink product dimensions.

In accordance with the basic procurement policy of the NGK Group's Supply-Chain CSR Guideline, NGK’s production of tin-plated beryllium copper products and copper-nickel-tin products strictly avoids the use of any form of conflict minerals.

Copper Beryllium can attain the tensile strength of 1500N/mm2 through precipitation hardening and can withstand very high bending stress.

The electrical conductivity of beryllium copper ranges from 20 to 70% IACS, depending on alloy and temper. Copper Beryllium is often used as a high current density spring material.

Age hardenable material can be formed into complicated shapes and precipitation hardened afterwards. Among Mill-hardened material,which does not require heat-treatment after stamping or forming, "Type-B"and"Type-S"have especially well-balanced performance in strength and formability.

Because Copper Beryllium exhibits excellent resistance to fatigue, it is also used in components where a longer life in service with a cycle stress environment is needed.

Copper Beryllium has excellent corrosion resistance, nearly the same as Nickel Silver.

Copper Beryllium is suitable for EMC shielding applications. The magnetic permeability is 1/100 of stainless steel (SUS304).

Due to less stress relaxation at elevated temperatures Copper Beryllium can be used in a wide range of temperatures with little loss of mechanical properties.

Inquiry about Special Metals

Sales & Marketing Division