Products

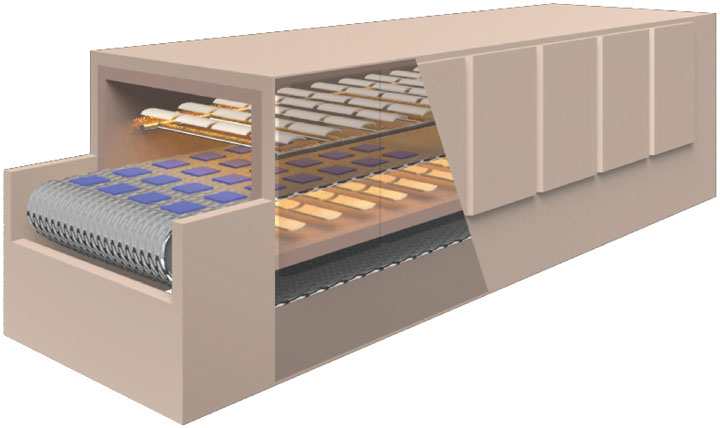

Mesh Belt Kiln

Product tags:

Overview

The Mesh Belt Kiln is a continuous kiln that transports products using a metal or resin belt conveyor. A gas supply and exhaust system can be installed and a heat source can be selected according to the process conditions.

Features

- With this heating kiln, products can be transported and heated while stationary on the conveyor, reducing the risk of displacement between entry and exit.

- The transport method can be switched easily between takt and continuous transport to match the product and the preceding and following equipment.

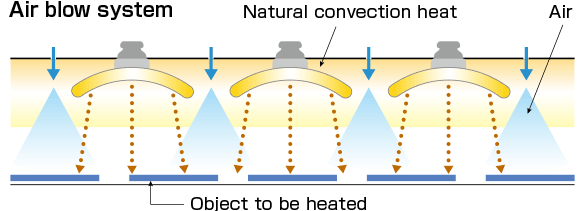

- The NGK original ceramic heater and air blow system deliver highly uniform heating.

- The kiln provides advanced atmosphere control.

Gas Supply System

- Gas can be supplied from front/back, left/right, or top/bottom.

- The gas flow rate can be controlled.

- The dew point (D.P) can be controlled.

- Includes an oxygen concentration gauge, hydrogen concentration gauge, and dew point gauge.

Exhaust System

- The exhaust flow rate can be adjusted using the ejector exhaust mechanism.

Examples of use

Carbon fiber, Thermoplastic resin, Greensheet, Food, Plastic products, Electronic components, Catalysts, Mat material, etc.

Specifications

| Temperature | R.T.~1,100℃ |

|---|---|

| Atmosphere | Air, N2 + H2(1% or less) |

| Heat source | Far-infrared heater, Near-infrared heater, Wavelength-control heater, Electric heater, Hot air |

| Belt material | Metal, Resin |

List of Heating Systems

Inquiry about Industrial Heating Systems

Please apply with the contact form and give us your comments or questions.