Products

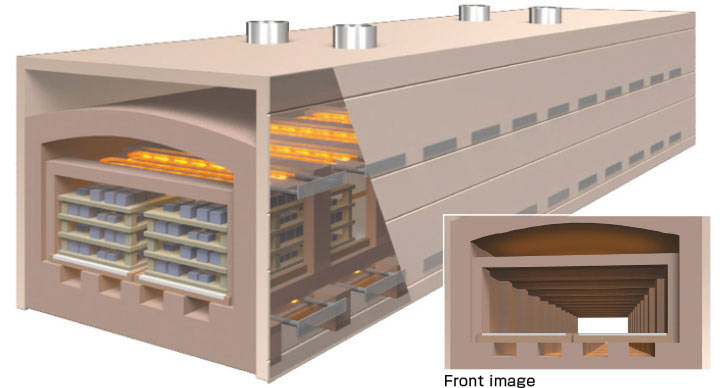

Pusher Kiln

Overview

Automatic Pusher Kiln

Layout example

Examples of stable kiln internal atmospheres

| Hard ferrite | Air |

|---|---|

| Soft ferrite | N2、Air |

| Ceramic capacitor | Air、H2 |

| Semiconductor capacitor | H2 + N2 |

| Varistor | H2 + N2 |

| Thermistor | N2、Air |

| Piezoelectric ceramics | Air、N2 |

| Alumina substrate | Air |

| Tungsten metallization | H2 + N2 |

Features

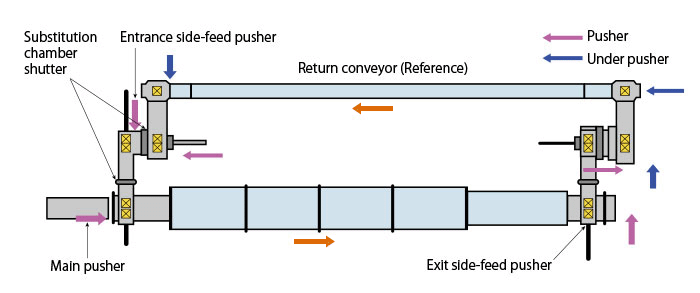

-

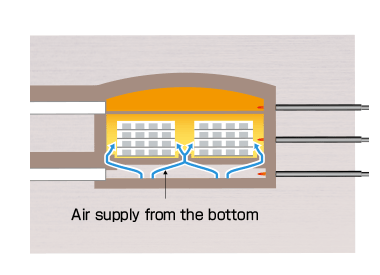

Uniform temperature and atmosphere

These kilns can maintain a stable internal atmosphere. Because gas can also be supplied from the bottom of the kiln between the rows, this reduces the temperature and atmosphere variation in the up/down and left/right directions.

-

Capable of mass production

Because the kiln uses multi-level transport, it is capable of mass production with improved surface area productivity. By using it together with tools that have good thermal conductivity, it is possible to shorten the profile.

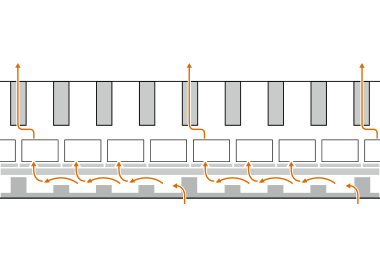

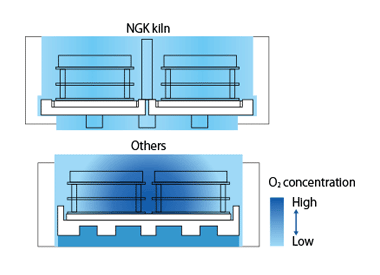

Uniform gas flow

Special labyrinth structure

Oxygen concentration distribution

Producing a uniform gas flow results in little variation in the oxygen concentration or temperature distribution, allowing a uniform atmosphere to be maintained inside the kiln.

Examples of use

Lithium-ion battery materials(cathode and anode), Ceramic capacitor (MLCC), Piezoelectric element, Thermistor, Varistor, Inductor, Ferrite, Phosphor, etc.

Specifications

| Temperature | Maximum heating temperature 1,650˚C |

|---|---|

| Atmosphere | Air, N2, O2, N2 + H2 |

| Heat source | Electricity, Gas |