Products

Roller Hearth Kiln

Overview

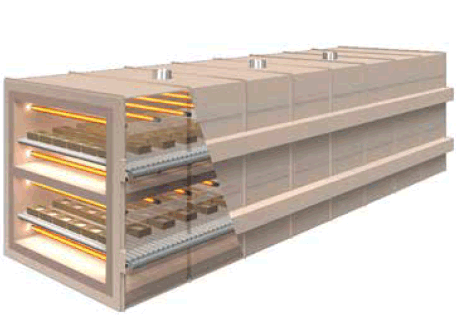

The system provides firing conditions that meet customer needs through atmosphere controls for air, N2, O2, N2 + H2, and other gases, as well as precision temperature controls for each of the preheating, firing, and cooling zones. The system contributes to the production of all solid-state batteries (solid electrolyte) and cathode and anode materials for lithium-ion batteries, essential for applications targeting carbon neutrality, for a carbon-zero society, and for MLCC and other electronic components that support our digital society.

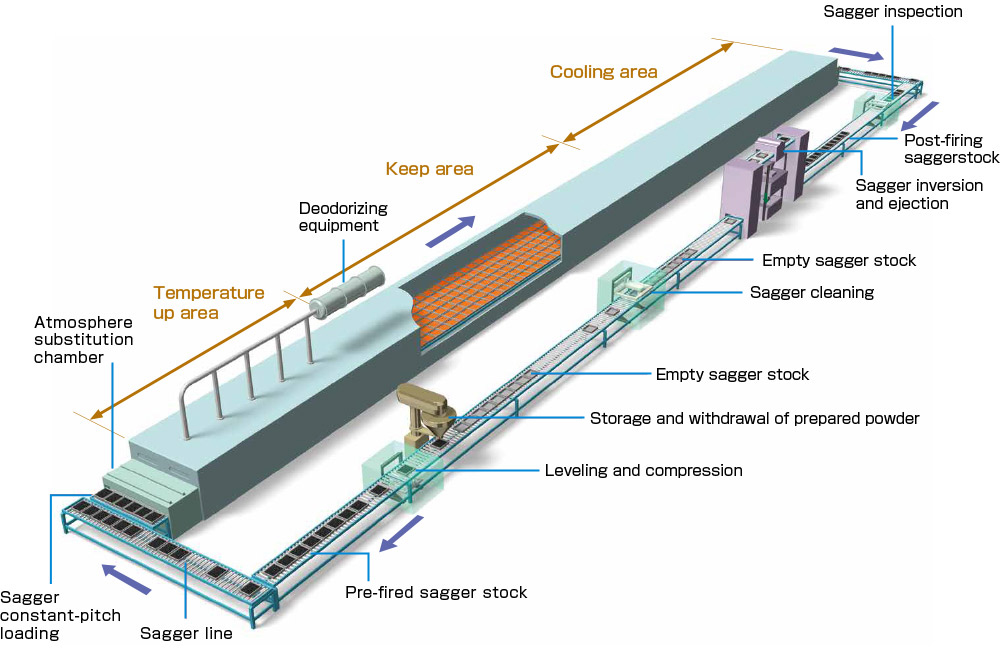

According to the powder material type, NGK adds the following processes and offers proposals for improving production efficiency and product quality.

Material powder feeding and compression

- Powder compression increases production volume.

- Optimization of the feeding shape minimizes temperature unevenness and improves product quality.

Powder collection system

- This system cools the powder as it is collected. (Allows the cooling area to be shortened.)

Features

Improvement in production performance

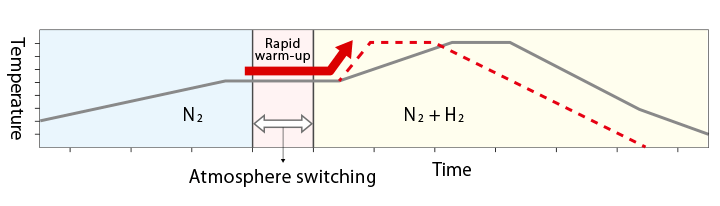

Atmosphere control technology

Rapid warm-up, Atmosphere switching technology

Boosting productivity while conserving energy

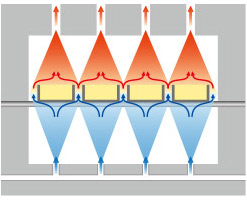

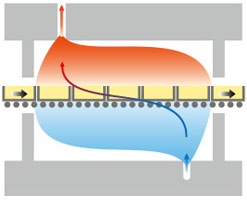

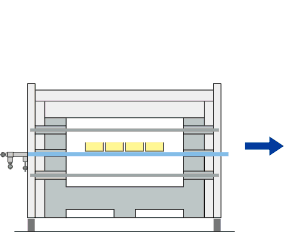

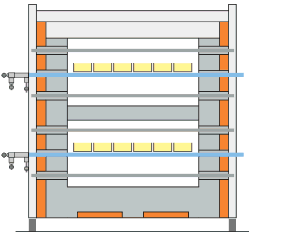

Multi-row/multi-stage tray transport to improve area productivity

NGK’s high-strength rollers achieve multi-row/multi-stage tray transport for efficient production in limited site areas, typically yielding three-fold improvements in productivity.

For the same production volume

Energy saving

Atmosphere gas saving

Promises stable operation.

Reduced contamination

Total engineering for preceding and following systems

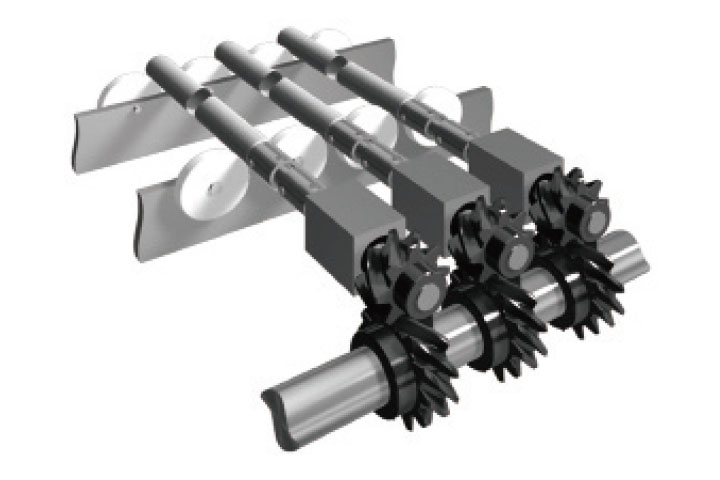

Stable product transport

A Universal Joint system, a proprietary NGK technology, achieves high precision transport on both sides of the rollers, enabling stable product transportation even in long furnaces.

Examples of use

Lithium-ion battery materials (cathode and anode materials, precursor), Solid state battery (Solid electrolyte), Solid oxide fuel cell (SOFC), Solid oxide electrolyzer cell (SOEC), Precursor, Ceramic capacitor (MLCC), Piezoelectric element, Thermistor, LTCC, Inductor, Ferrite, Magnet, Barium titanate, Catalyst, Sanitaryware, Tiles, Glass substrates, etc.

Specifications

| Temperature | Maximum heating temperature 1550˚C |

|---|---|

| Atmosphere | Air, N2, O2, N2 + H2, N2 + H2O |

| Heat source | SiC heater, Metal heater, Gas |

| Roller | SiC, Mullite, SUS |

| Kiln length | 1〜100m |

List of Heating Systems

Inquiry about Industrial Heating Systems

Please apply with the contact form and give us your comments or questions.