Products

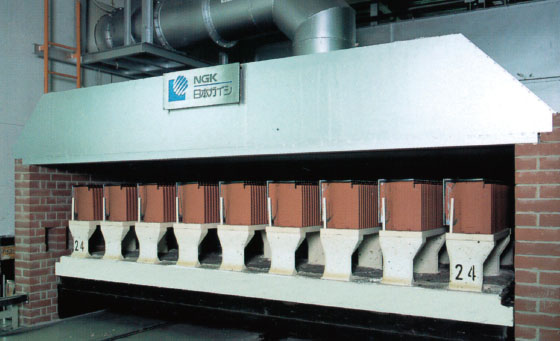

Tunnel Kiln

Overview

Features

-

Supports energy savings with the use of fiber kiln materials and the NEWSIC Si-SiC kiln material.

The use of fiber kiln materials and the high-strength NEWSIC shelf boards provides energy savings. These materials also help achieve rapid warm-up and cool-down, and enable intermittent operation such as stopping kiln operation on weekends.

-

Supports fully automated total production plants.

Full automation is possible, including the kiln car stock line and other processes, helping to reduce energy consumption. This also makes it possible to automatically perform kiln ignition and shutdown in order to stop operation on weekends.

-

Allows mass production of large-size products, as well as mixed production of multiple product types.

-

Supports high temperatures up to 1,850°C.

-

The use of fiber kiln materials helps achieve rapid warm-up and cool-down.

-

Capable of energy savings through waste heat recovery, lightweight kiln cars, and air-fuel ratio control.

-

Feedback control of the kiln car feed speed allows more stable production volumes.

Equipment flow combining energy-saving technologies

- Active reuse of cooling zone air (waste heat recovery)

- m-value control for reduction of excess air

Example of use

Examples of use

Roof tiles, Tiles, Sanitaryware, Insulator, Catalyst, Refractory, etc.

Specifications

| Temperature | 〜1,850℃ |

|---|---|

| Usable kiln width | 〜4.4m(For tiles) |

| Kiln length | 〜120m |

| Kiln height | 〜2.0m |

List of Heating Systems

Inquiry about Industrial Heating Systems

Please apply with the contact form and give us your comments or questions.