Sustainability

Environmental Pollution Prevention

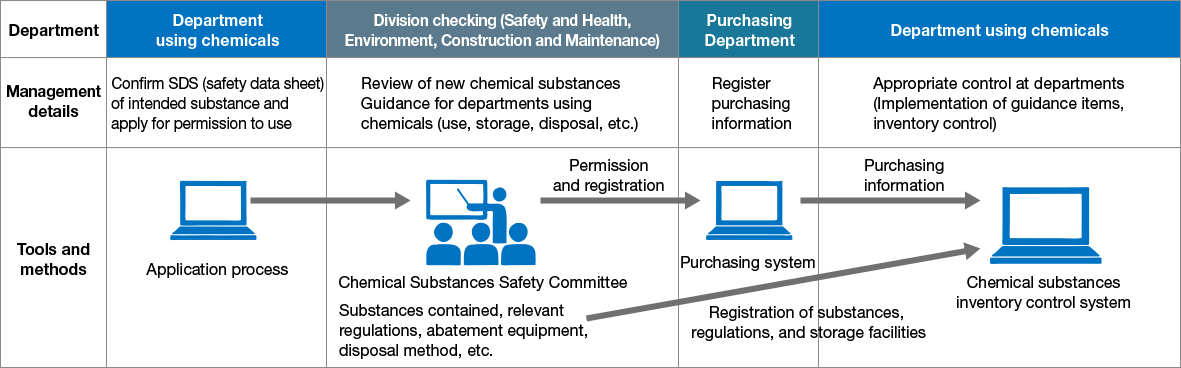

Chemical Management

The NGK Group abides by laws, guidelines, and other rules on chemical substances by maintaining a proper level of management for chemicals, and constantly striving to improve this level. Before new chemicals are used by each department, the Chemical Substances Safety Committee determines the pros and cons of using these chemicals and provides confirmation and guidance concerning what precautions must be taken for their usage and disposal. For chemicals that have already been used in the department, the site’s chemical substances committee and chemical substances patrol team determine and confirm the state of chemical management and provide necessary guidance. We also follow information regarding changes in chemical substance-related regulations and share this within the NGK Group to ensure proper chemical substance management policies are implemented.

Group companies in and outside Japan survey and understand regional rules and regulations so that chemical substances can be properly managed.

Chemical Management Flowchart

Commitment Concerning Hazardous Substances

The NGK Group aims to reduce the amount of hazardous substances used, in accordance with the NGK Group Environmental Policy. Regarding raw materials, we present our suppliers with a hazardous materials list, and require that they comply with the hazardous substances management stipulated by the NGK Group Supplier Code of Conduct and the NGK Group Green Procurement Standard.

NGK Group Environmental Policy

NGK Group Supplier Code of Conduct

NGK Group's Green Procurement Standard

Reducing Emissions of Hazardous Waste

In order to comply with legal processing deadlines, we conduct thorough investigations into PCB-containing waste at NGK and our Group companies, then proceed sequentially with extraction, storage, and disposal. We outsource disposal to contractors who hold PCB disposal permits, and check to make sure disposal is handled properly.

Atmospheric Emissions Management

NGK manages a database of approximately 7,000 pieces of equipment, in accordance with the Act on Rational Use and Appropriate Management of Fluorocarbons. And we curb undue emissions (improper emissions) by centralizing management information about things like simple inspections, periodic inspections, maintenance, and leaks.

We comply with legal limits on soot emissions from facilities through voluntary management items and periodic measurement in accordance with items stipulated by laws and ordinances, and through constant monitoring of critical items. Moreover, NGK Group plants are registered as emergency cooperation plants under the Aichi Prefecture Emergency Handling Procedures for Photochemical Smog and the Ishikawa Prefecture Air Pollution Emergency Measures Implementation Outline. When elevated photochemical oxidant levels cause photochemical smog warnings to be issued, we cooperate with measures to reduce emissions in accordance with these guidelines through actions such as halting facilities that produce NOx.

Wastewater Management

To avoid impacts on people’s health and living environments, we have set voluntary standards with respect to wastewater to supplement the standard compliance values set by laws, ordinances, etc. These trigger alarms or shutoff at or below levels required by wastewater standards. Moreover, we perform management to ensure that even in cases of emergency, levels do not surpass regulatory standard values.