Sustainability

Waste Reduction and Effective Use of Resources

The NGK Group conducts business which utilizes natural resources primarily in the procurement of raw materials for ceramic products, and generates a considerable amount of waste in the process. Therefore, we believe that properly managing waste and resource use, and improving resource efficiency, will help to reduce the impact on the environment. In addition, we believe that increasing resource efficiency and appropriately responding to the shift to a recycling-oriented society will make NGK more competitive in terms of cost reduction and stable supply.

Based on this line of thought, the NGK Group sees promoting resource recycling as an important issue in the environmental sector, and will advance relevant initiatives.

Targets and Achievements

Reducing Waste

To meet our FY2025 target for reduction of waste, the NGK Group has formulated and is implementing an annual improvement plan, similar to that for CO2 emissions, aimed at reducing the generation of waste materials.

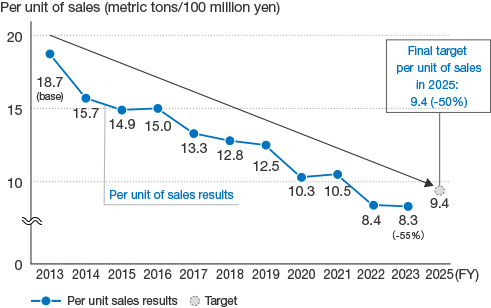

We achieved reduction rate of 62% per unit of sales in FY2024 compared to FY2013, achieving our annual target and even reaching our FY2025 target of 50% reduction. This is the result of continual improvement activities by the manufacturing department, including improving yield and raw material recovery rate in production sites.

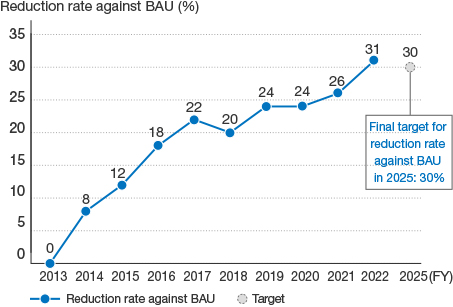

Our reduction rate against BAU, which indicates the improvement per unit of sales over FY2013, was 35%. So, we have achieved our annual target, as well as our target of 30% for FY2025. Looking towards the final year of our fifth 5-Year Environmental Action Plan, we will continue our waste reduction activities to maintain this progress.

Ratio of actual waste generated to the amount of waste expected to be generated assuming production intensity has not changed from the base year.

Waste Materials (all NGK Group production sites)

Reduction Rate against BAU (all NGK Group production sites)

Waste Recycling

The NGK Group is actively striving to promote waste recycling by thoroughly sorting materials and considering methods to recover resources from waste.

Since FY2017, we have shared methods to recover resources and information about waste disposal companies with all of our production sites in Japan. We are working to promote efficient and reliable resource recovery by selecting trustworthy disposal companies.

These continuing efforts have allowed us to maintain a continual domestic recycling rate of 99% or higher from FY2013 onward, as stated among the goals of our 5-year action plan. And we are recycling ceramic waste from the manufacturing process as raw materials for concrete, and other materials for use in roadbeds.

Because conditions vary by region outside Japan, we are setting target values which take into account the actual state of affairs in each country. We maintain an average recycling rate of roughly 90% for our 18 Group companies outside Japan that are engaged in manufacturing (excluding the three companies for which recycling is difficult).

Reducing Waste Plastics

Since FY2023, the NGK Group has disclosed the amount of waste plastic generated during production. 1,777 metric tons of plastic waste was generated in FY2024. From here on out, we will work to reduce the amount of plastic waste generated by reviewing the processes that use plastic and the sorting out of plastic when it is generated.

In addition, it had previously been difficult for NGK to recycle the plastic drums used to import raw materials after they had been used and worn out. However, through cooperation with a plastic recycling manufacturer, 100% of them are now recycled into the RePlagi series of industrial/construction materials developed and sold by that manufacturer. These are used as replacement square timbers, replacement plates for steel plates, etc.

Support for a Circular Economy

In Europe, new battery regulations and eco-design regulations are being formulated towards achieving a circular economy. The NGK Group will closely follow these trends, and respond appropriately to the demands of society.

Going forward, we will put together and disclose examples of resource recycling in the NGK Group. At the same time, we will consider an action plan for bringing about a recycling-oriented society by 2030 as laid out in our NGK Group Environmental Vision. Moreover, we have begun to consider the possibility of recycling plastic materials generated as waste in our business sites. One example is how we created table tops and facility signs from waste plastic generated in our production process, and placed it in our Co-Creation Center “NGK Collaboration Square DIVERS”. In FY2024, we strove to spread awareness about sustainability by creating novelty items for employees using the same materials. We are also considering utilizing them for packaging materials and in our production sites.

Table tops and facility sign installed at NGK Collaboration Square DIVERS