Sustainability

Products and Services Contributing to Environmental Protection

The NGK Group regards contributing to society through our business activities to be one of our most important missions. We leverage the technology we have cultivated for more than a century since our founding, to develop and provide products and technologies that contribute to the global environment.

Developing and Distributing Products/Services Contributing to Environmental Protection

The fifth 5-Year Environmental Action Plan, which began in FY2021, establishes a goal of increasing the number of registered carbon neutral products and services among our products contributing to environmental protection. In FY2022, we registered ABASHIRI ELECTRIC POWER, which have been using NAS batteries to provide stable renewable energy supply, as a service business company contributing to regional carbon neutrality. Moreover, we registered AMB substrates in FY2023, and our NAS MODEL L24 improved NAS battery in FY2024.

We now offer a lineup of 12 products/services contributing to environmental protection. Six of these are related to carbon neutrality. Going forward, we plan to follow up on our NAS batteries by focusing on developing new carbon neutral products and providing services, such as nickel-zinc rechargeable battery, and CO2 separation membranes which are expected to contribute to Carbon Capture and Utilization/Carbon Capture and Storage (CCU/CCS). Moreover, in FY2024, we invested 0.66 billion yen in research and development for improving products related to preventing air pollution, and 0.03 billion yen in developing products related to protecting water resources.

FY2024 Products/Services Contributing to Environmental Protection

Our Definition of Products/Services Contributing to Environmental Protection

We define products and services contributing to environmental protection as those that fulfill any of the following requirements.

- Items recognized or certified by third party organizations

- Items that help limit or reduce the impact on the Earth’s environment

- Items that help reduce the impact on the local environment

Development and Creation of Products/Services Contributing to Environmental Protection

Considering Sustainability When Designing Products

The NGK Group develops and designs our products and services in accordance with the NGK Group Corporate Business Principles and Code of Conduct. We also work to comply with the requirements of our customers. And in the NGK Group Environmental Policy, we clearly state that we promote the development and proliferation of products/services contributing to environmental protection as part of our environmental/social contribution. We confirm the progress of these initiatives through periodic internal audits and third-party audits of our environmental management system.

Contributing to Carbon Neutrality

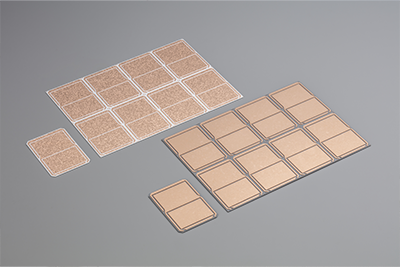

AMB Substrates for Power Modules

(CN-related products)

AMB substrates are products used in power modules for motor drive control and generator power conversion control. Their role is to dissipate heat generated by the semiconductor element by conveying it to the cooler.

The NGK Group's AMB substrates for power modules achieve high reliability and excellent heat discharge characteristics, by means of our unique bonding technology. They maximize the performance of power semiconductors. As the switch to EVs makes progress worldwide, we expect this product to contribute to carbon neutrality through greater utilization in EVs and HEVs. We will help to solve societal issues through our unique ceramic technologies.

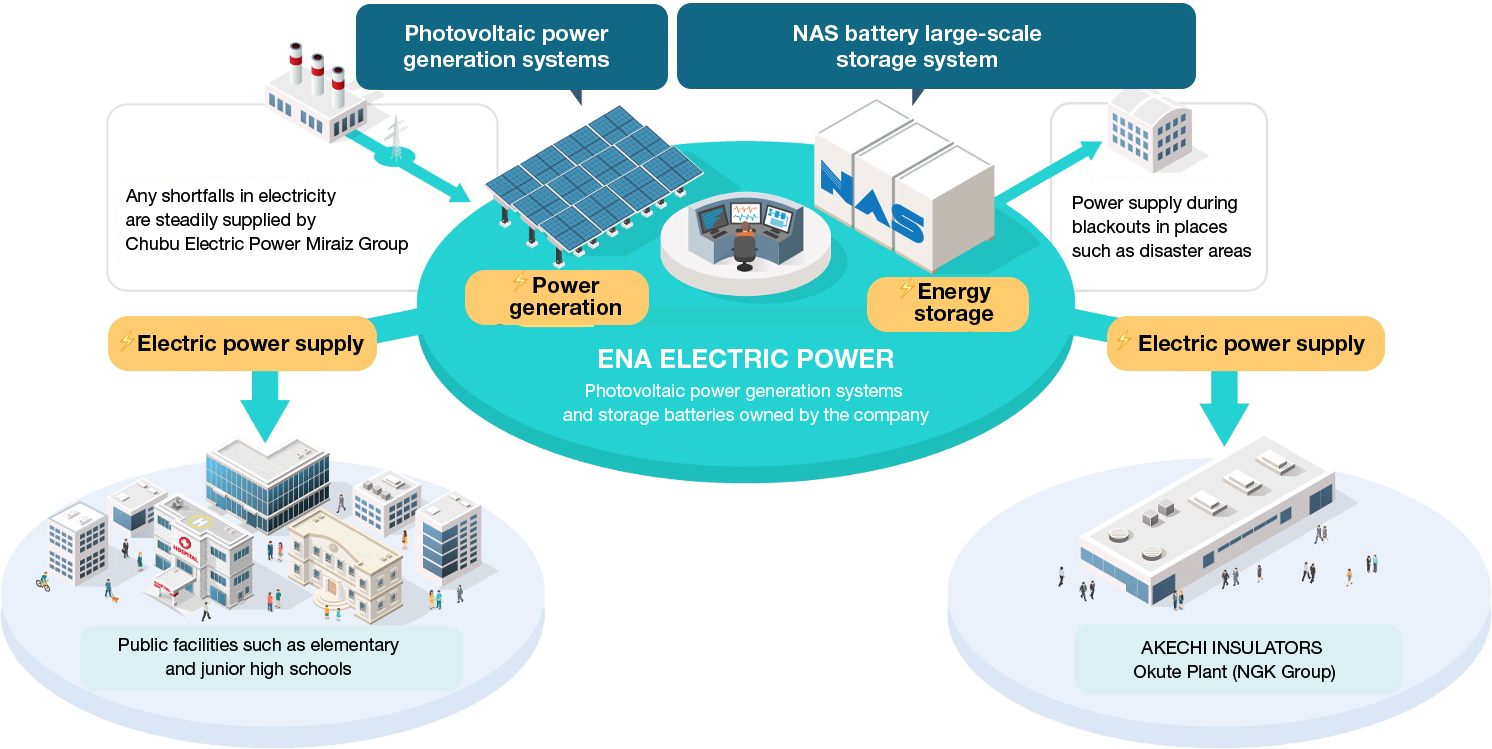

Local Renewable Energy Electric Power Supply Service by ENA ELECTRIC POWER and ABASHIRI ELECTRIC POWER

(CN-related services)

In 2021, the city of Ena, Chubu Electric Power Miraiz, and NGK established ENA ELECTRIC POWER.

ENA ELECTRIC POWER installed photovoltaic power generation systems and NAS batteries in empty lots and the rooftops of public facilities in Ena. By supplying electricity to public facilities and AKECHI INSULATORS of the NGK Group, the systems are contributing to the energy independence and carbon neutrality of Ena.

Moreover, in 2022, NGK and the city of Abashiri together established ABASHIRI ELECTRIC POWER to supply the same kind of locally produced renewable energy.

NAS Batteries

(CN-related products)

The widespread adoption of renewable energy sources that do not use fossil fuels or emit carbon dioxide (CO2) is underway. Sodium Sulfur (NAS) Batteries can help stabilize the grid by charging and discharging to absorb the fluctuations in power output from wind and solar power generation due to natural phenomena.

In addition, as renewable energy use increases, it becomes more challenging to balance electrical supply with demand due to factors such as excess electrical power at different times or seasons. NAS batteries can use their large capacity to balance supply and demand by storing excess power, helping to support the expansion of renewable energy.

NAS MODEL L24 Improved NAS Battery

(CN-related products)

In FY2024, we began international sales of our NAS MODEL L24 improved NAS battery, which builds on the performance of our existing container-type NAS batteries.

The NAS MODEL L24 can operate with fewer installed units than existing products, and helps to reduce the life cycle cost of customer storage battery systems by roughly 20%.

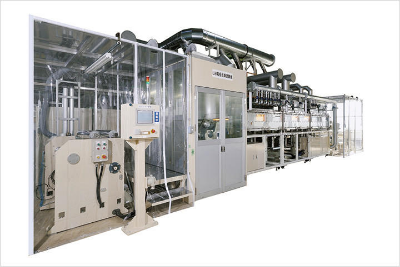

Wavelength Control Drying System

(CN-related services)

Our wavelength control drying system uses an original heating unit developed by NGK to accelerate solvent drying.

This system uses the selective irradiation of specific infrared wavelengths effective for evaporation to dry materials in 1/2 to 1/3 the time required by conventional drying methods which use heat. Electricity consumption is also cut by 30 to 50%. Binder segregation, which indicates deviations in density due to the drying of the internal components of the coatings, is also curtailed by 30 to 40%.

Preventing Environmental Pollution

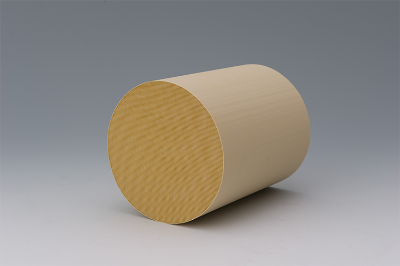

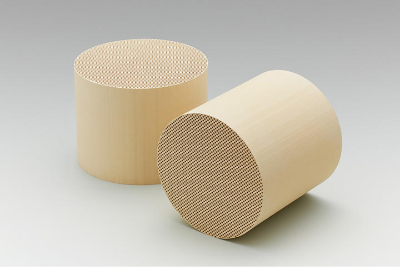

HONEYCERAM

HONEYCERAM are ceramic substrates for automotive catalytic converters for purifying automobile exhaust gases of hazardous constituents. They have a catalyst which detoxifies hazardous substances through a chemical reaction, and a honeycomb structure that improves their purifying abilities by ensuring a large contact area with exhaust gases.

Since mass production began in 1976, we have produced a cumulative total of over 2.0 billion units. These ceramic products have become indispensable to the purification of automotive exhaust gases.

The HONEYCERAM manufactured by the NGK Group can reduce nitrogen oxide (NOx)*1 emissions by 4 million metric tons per year. This is equivalent to roughly double the annual amount of NOx*2 emissions in Japan.

1 Assuming new cars not equipped with exhaust gas systems are equipped with the same systems

2 Source: OECD Environment Statistics (2012)

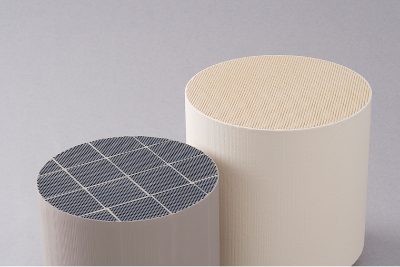

Diesel Particulate Filters (DPFs)

DPFs are porous ceramic filters fitted to the exhaust systems of diesel vehicles. Using micropores to securely capture particulate matter (PM) purifies the exhaust gas of diesel vehicles and greatly contributes to reducing atmospheric pollution. The NGK Group is the only manufacturer who mass produces two types, cordierite and silicon carbide. And we are further developing our ceramic technologies for diesel vehicles.

Gasoline Particulate Filters (GPFs)

GPFs are ceramic filters that remove the particulate matter emitted by gasoline engines.

We have succeeded in developing GPFs based on the technology behind particulate matter (PM) removal filters for diesel engines (DPFs). We combined this technology with proprietary micropore creation and control technologies to achieve both high PM capture efficiency and low pressure loss (low fuel consumption and high power output). In 2012, we became the first in the world to put GPFs into practical use, and we began full-scale mass production in 2016.

Going forward, we will work to meet the needs of society as automotive emissions regulations are strengthened worldwide.

In-Vehicle High-Precision NOx Sensors

The world’s first in-vehicle sensor that can precisely measure nitrogen oxide (NOx) concentration in exhaust gases in real time. It measures the concentration of NOx in exhaust gasses at a ppm (parts per million) level, catching even minute amounts of NOx. It precisely controls the exhaust gas purification equipment in diesel vehicles to reduce the amount of NOx emitted, and promote the spread of clean diesel vehicles.

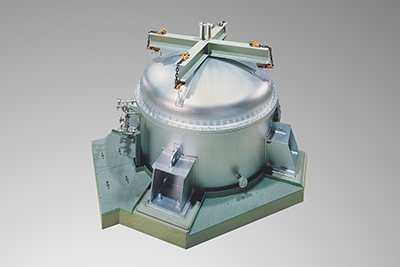

Low-Level Radioactive Waste Treatment Systems

The NGK Group produces various equipment that employs our proprietary processing technology and exhaust gas dust removal technology, using high performance filters, to safely process low-level radioactive waste generated by nuclear power facilities. We have delivered these to nuclear power stations and related research facilities all around Japan.

Our broad engineering capabilities span design, manufacturing, and construction. These combined with long-term maintenance support, allow us to achieve stable, advanced radiation removal that contributes to the safe operation of nuclear facilities.

We are also working to develop systems for processing the various new waste generated as aging nuclear reactors are shut down and dismantled.

Importance of treating radioactive waste

When it comes to treating and disposing of the waste generated in the radiation control areas of nuclear power plants and the like, preventing the release or leakage of radioactive material is of the highest importance. It must be treated and disposed of in a different manner to general waste.

Micro-Lenses for Ultraviolet LEDs

Micro-lenses for ultraviolet LEDs are quartz glass lenses which the NGK Group has developed for use with the ultraviolet LEDs intended to replace mercury lamps. Ultraviolet light sources are seeing widespread use in applications such as sterilization of water and air. Currently, such applications use mercury lamps. But in light of new laws and regulations based on the Minamata Convention on Mercury, their use will be banned in the future. This is driving interest in ultraviolet LEDs, which do not use mercury. Our micro-lenses for ultraviolet LEDs feature a cavity (space) to hold the ultraviolet LED chip. This increases the efficiency of the ultraviolet LED while reducing its cost.

Environmental Labeling and Declarations

Since the NGK Group focuses mainly on B2B products, we do not presently conduct environmental labelling. However, we will respond appropriately if cases arise where such labeling is needed.