Sustainability

Occupational Safety and Health

Basic Approach

The NGK Group operates an ISO 45001-certified Occupational Safety and Health Management System (OSHMS) in line with its Safety and Health Policy. The OSHMS serves as a mechanism for the ongoing, systematic achievement of worker safety and health initiatives. By strictly implementing this system and conducting risk assessment-based safety measures, we strive to raise the level of occupational safety and health throughout the entire Group, including for contractors on-premises.

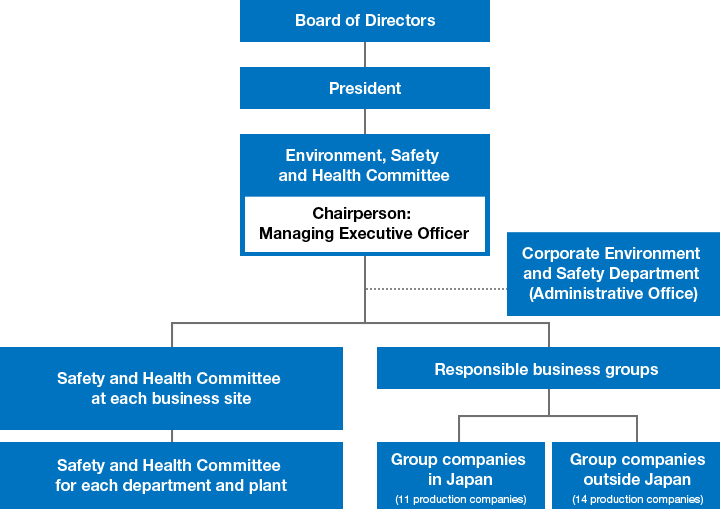

Safety and Health Management Promotion Framework

NGK has made the chairperson of the Environment, Safety and Health Committee the person responsible for overseeing safety and health in order to raise the level of safety and health for the entire Group. This committee is chaired by the Director and Managing Executive Officer and meets at least biannually to deliberate and determine the Group’s initiatives and action plan as well as monitor the results of activities, situation of work-related accidents and countermeasures. The committee reports to the Board of Directors which also monitors its activities. Moreover, every business site holds Business Site-Specific Safety and Health Committee meetings monthly led by relevant labor representatives of every department and attended by General Safety and Health Manager (directors of each site/executive officers). In addition to promoting awareness of Group activities and action plans, the committees and deliberate important matters related to safety and health unique to each business site, and ensure findings are made known throughout each workplace by its Safety and Health Committee members.

Safety and Health Management Organizational Chart

Enhancing Safety and Health Activities

NGK views the enhancement of safety and health activities as one of its top priorities. In addition to rigorous operation of our occupational safety and health management system, we developed our third three-year action plan to start from FY2023. It is built around the key themes of compliance, governance, and risk reduction. We are promoting safety and health activities with our action policies defined as ensuring thorough legal compliance, further enhancing our Group governance structure, and preventing serious accidents and disasters. Concerning preventing serious accidents and disasters, in addition to comprehensive risk assessments covering existing facilities and operations, when introducing new facilities or operations or modifying operations, we conduct a thorough risk assessment in advance to eliminate risks or reduce them to an acceptable level.

Results of FY2024 Activities

| Medium-Term Action Plan | Fiscal year implementation items | Key Activities |

|---|---|---|

| Compliance | Strengthen mechanisms for compliance with laws and regulations | We carried out training for managers/representatives, in addition to conducting general surveys and corrective action at all business units including Group companies concerning compliance with laws and regulations related to safety and health. Moreover, we have put internal regulations in place to prevent non-compliance with laws and regulations, such as failure to report to the government. At the same time, we are building a database that will allow us to respond to all legal requirements related to safety and health. |

| Group Governance | Strengthen safety and health functions in each business group | We have clarified the division of roles between the department which oversees safety and health at the head office, and the safety and health departments in each business group. We have largely finished setting up an autonomous structure that enables the safety and health departments at each business group to manage/promote safety and health at plants and group companies under their jurisdiction. |

| Risk reduction | Reduce the risk of serious accidents or injuries | We comprehensively extracted and identified high severity risks related to getting caught and entangled in rotating machinery, electric shock and explosion for equipment at all production sites, including those outside Japan. We implemented operational solutions for curtailing risks (administrative measures) and completed equipment countermeasures (upgrades and modifications). We continue to implement risk assessment training aimed at improving our ability to extract the sources of risks. |

Numerical Targets

NGK has set the following numerical targets for 2025.

- Zero fatal or serious accidents throughout the Group

- Group-wide lost-worktime accident severity rate of 0.010 or less

In 2024, we achieved zero fatal or serious accidents throughout the Group. On the other hand, the group-wide lost-worktime accident severity rate climbed to 0.015, failing to meet our target value of 0.010 or less.

Work-Related Fatalities

Work-Related Accidents

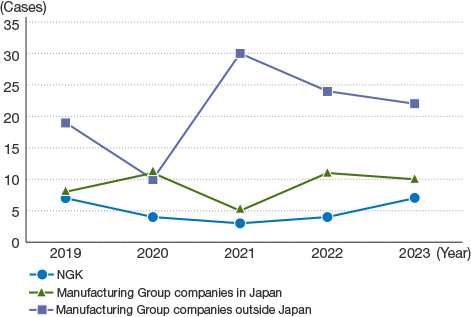

Trends in Work-Related Accidents

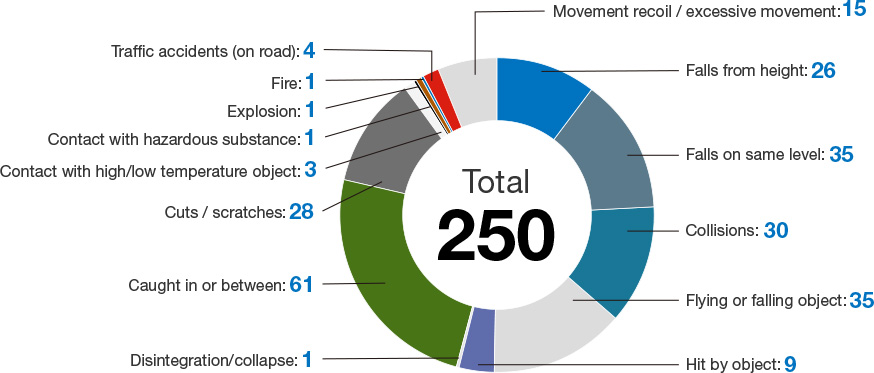

Non-lost Worktime and Lost Worktime Accidents by Type

(past 7 years; NGK Group consolidated)

Response to Work-Related Accidents

In the event of a work-related accident, following the NGK Group’s rules, we promptly notify relevant departments and convene committees such as the Work-Related Accident Deliberation Committee pursuant to the regulations of each company. This ensures that we are able to thoroughly identify the cause and implement countermeasures against future recurrence.

In 2024, there were 50 non-lost worktime and lost worktime accidents Groupwide. Broken down, these included six at NGK, 10 at manufacturing Group companies in Japan, and 34 at manufacturing Group companies outside Japan. The number of minor accidents at Group companies outside Japan increased, causing group-wide accidents to rise 30% over last year. However, we have strengthened our risk management and equipment measures in order to prevent serious accidents. And because we have continued our risk assessment training for personnel in charge of manufacturing sites (training to discover potential hazards), accidents with a severity of serious injury or higher have significantly decreased. Furthermore, accidents involving getting caught in rotating machinery, electric shock, or explosion (which we addressed as priority activities) did not occur.

Number of Contractor Accidents Severe Enough to Result in Lost Worktime

Number of Contractor Deaths

Severity Rate (Number of Lost Workdays per 1,000 Hours Worked)

Lost Time Injury Frequency Rate (Employees)

Occupational Illness Frequency Rate

External Certification of Occupational Safety and Health Management System

To continuously raise the level of occupational safety and health in workplaces, we encourage companies in the NGK Group to acquire international certification for occupational safety and health management systems.

In 2017, NGK’s Nagoya Site received the first ISO 45001 private certification in Japan. In 2018, all other NGK sites and plants in Japan received ISO 45001 certification and JIS Q 45100 certification.

As of June 2021, all 26 manufacturing Group companies in Japan and overseas have completed the acquisition of ISO 45001.

Acquisition of Occupational Safety and Health Management System Certification

Safety and Health Training

NGK provides training to employees and assists with their acquisition of qualifications/licenses required under safety and health laws and regulations. Our training includes various in-house programs on safety and health along with curriculum sourced from outside NGK. In FY2024, a total of 2,217 employees received in-house group training concerning safety and health. The breakdown includes rank-based training/training for newly-promoted employees (670), danger prediction training (1,478), and ISO 45001 internal auditor training (69). This excludes training conducted by each department such as worker training, job rotation training, risk assessment training, external training for crane operators and the like, safety officer training, and safety assessor training.

Main Training Programs

| Training programs | Training curriculum |

|---|---|

| Legal training | Group training mainly for managers through videos that provide a summary of safety and health related laws and regulations |

| Internal safety and health training | In-house group training required of employees, including training on dust, KYT (hazard prediction training), risk assessment, etc. |

| External safety and health training | Training conducted offsite required of employees, including for workplace supervisors, low-voltage electricity, organic solvents, and for information equipment workers, lift/crane operators and various operation chiefs |

| New employee training | Group training for new graduate hires and individual training provided to newly assigned employees including temporary employees |

| Job rotation training | Training conducted by each department for employee transfers and work changes |

| Stratified education /Promotion training | Training provided at the time of promotion, including new promotions as well as newly appointed assistant managers, managers, general managers, and directors of business sites Stratified education training is provided to new graduate hires, mid-career hires, and workers promoted to regular employee status |

| Internal auditor training | Group training for the purpose of developing and improving the level of ISO 45001 internal auditors |

| Worker training | Training and exercises for frontline work are conducted to evaluate skill level and certification of work proficiency |

| Frontline management training (safety officers) | (See below) |

| Danger-Prediction Training Center | (See below) |

Acquisition of Safety Officer Qualification

To increase their managerial skills related to safety, under our 3-year plan from FY2021 to FY2023, we trained all managers, plant managers, and general managers of manufacturing, technical, and R&D divisions to become Safety Officers through e-learning and encouraged them to obtain Safety Officer Qualification*. We also encouraged engineers of design and maintenance departments for in-house equipment and production engineers at our plants to obtain Safety Assessor Qualification*.

Safety Officer Qualification / Safety Assessor Qualification: Qualifications established and administered by The Institute of Global Safety Promotion (IGSAP). The qualifications certify that an individual possesses understanding and knowledge of safety or knowledge and skills of machinery based on international safety standards, respectively

New Expansion of Danger-Prediction Training Center

To prevent injuries mainly among young workers and inexperienced workers, in 2018 NGK established the Danger-Prediction Training Center at our Chita Site.

The training center features equipment that enables employees to safely experience work-related injuries that have occurred in the past including being caught in equipment or rotating machinery and work-related accidents such as electric shock or explosions. Combined with classroom learning using computer graphics, the training center offers practical programs taught by specialized personnel.

In 2020, we introduced a virtual reality system for experiencing dangers and rolled out a training program that allows participants to refine their sensitivities toward dangers in a more practical manner. In 2024, we also renovated our dojo, adding theme-based zones, and making efforts to make it more immersive and realistic. Moreover, we added videos and exhibits related to actual accidents to get participants to see accidents as something they need to take responsibility to avoid. This training program was rolled out to employees at Group companies in Japan as well, and as of FY2024, a cumulative total of 10,909 people have participated.