Sustainability

Initiatives toward Carbon Neutrality

NGK Group Environmental Vision and Carbon Neutrality

The NGK Group considers tackling climate change to be one of our material issues. As such, we are promoting efforts to tackle climate change. We endorsed the Task Force on Climate-related Financial Disclosures (TCFD) in 2020. We are encouraging initiatives toward carbon neutrality throughout our entire value chain with the aim of achieving net-zero CO2 emissions in our business activities. Furthermore, we formulated the NGK Environmental Vision in 2021. We are promoting activities aimed at achieving net-zero CO2 emissions by 2050 in accordance with our Carbon Neutrality Strategic Roadmap, which consists of four strategies, and our 5-Year Environmental Action Plan.

NGK Group Environmental Vision

Carbon Neutrality Strategic Roadmap and 5-Year Environmental Action Plan

Initiatives in Line with the Carbon Neutrality Strategic Roadmap

The NGK Group has identified the risks and opportunities associated with the transition to a carbon-neutral society in line with the TCFD recommendations. We have formulated the Carbon Neutrality Strategic Roadmap toward the realization of such a society. We are working to reduce risks and expand opportunities by promoting initiatives aimed at achieving net-zero CO2 emissions for each strategy in the roadmap.

Strategy 1: Development and Provision of Carbon Neutrality-related Products/Services

The NGK Group is promoting the development of technologies relating to CCU/CCS (capture, utilization and storage of CO2), hydrogen, methanation and other areas to contribute to the realization of carbon neutrality. We are also developing ceramic membranes that contribute to the separation of hydrogen and methane during hydrogen transportation and the reaction, separation, purification and other processes in CO2-derived fuel synthesis (e-Fuel). In addition, we are developing DAC modules and other products which adsorb and capture the CO2 that is released back into the atmosphere through ways such as the use of e-Fuel. We are promoting development with a focus on the technologies necessary to ensure the smooth circulation of carbon without stagnation to lead to the provision of carbon neutrality-related products/services.

NGK Group’s Technological Developments That Contribute to Carbon Neutrality

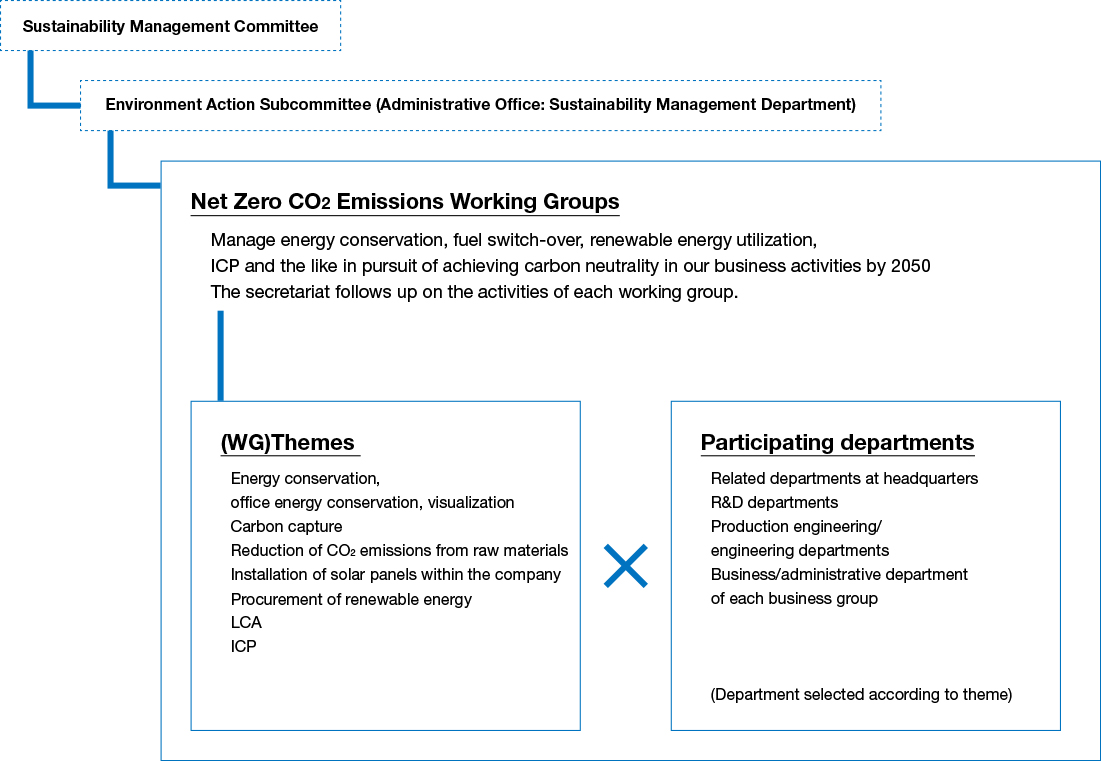

CO2 Emissions Reduction Promotion Framework (Strategies 2 to 4)

Strategies 2 to 4 are initiatives aimed at reducing CO2 emissions in the NGK Group. We believe it is important to set up a company-wide framework to work on these strategies. Therefore, we launched the Net Zero CO2 Emissions Project to build a framework toward the realization of carbon neutrality from FY2021 to FY2023. We established working groups based on Strategies 2 to 4 in this project. These working groups then promoted initiatives including improving energy conservation efforts, introducing carbon pricing, developing fuel conversion technologies and installing photovoltaic power generation systems. Each group formulated a roadmap and then built a framework to be able to continue activities independently over a three-year period. Each group has been continuing to promote initiatives based on their respective roadmaps since FY2024.

Net Zero CO2 Emissions Working Group Promotion Framework

Strategy 2: Top-Down Enhancement of Energy Saving (Energy Conservation (Manufacturing Departments and Back-office Departments) Working Group and ICP Working Group)

Top-Down Enhancement of Energy Saving

We believe it is important to first promote thorough energy conservation to reduce CO2 emissions. Energy conservation also leads directly to cost reductions. Therefore, we have set up a framework in which the heads of each manufacturing department take the initiative in working on energy conservation. We have established the Energy Conservation Promotion Council. This council, led by the heads of the manufacturing departments, meets twice a year to share the energy conservation activities of their departments. This is an opportunity to learn from each other. Moreover, the Manufacturing Engineering Department in the Head Office play a central role in an activity called “energy conservation patrols” which involve conducting assessments and providing guidance. These patrols support energy conservation activities suitable for each department. While the contents of the activities differ by department, each department is steadily working on its own set reduction targets. As a result, we achieved a reduction in CO2 emissions of 24,000 metric tons throughout the entire NGK Group in FY2024.

Increase in Efficiency of Manufacturing Processes

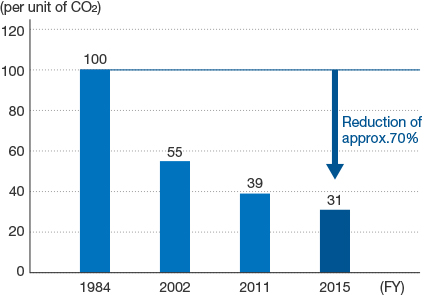

The NGK Group has been continuously working to increase the efficiency of manufacturing processes over many years starting with insulator manufacturing. We initially used coal or heavy oil as the fuel for the kilns used in the firing process essential to manufacturing ceramics. We have replaced this with natural gas and other energy sources. Together with this, we have switched from using conventional bricks to fibers for the kiln materials and updated the firing burners to those with higher efficiency. We have achieved an approximately 70% reduction in CO2 emissions from our continuous kilns over 30 years since the 1980s through those efforts. We are still now to this day maintaining and improving that level. In recent years, in addition to such large-scale improvements, we have been considering and promoting initiatives aiming for further increases in efficiency. These efforts include adjusting the air ratio during firing and effectively utilizing waste heat in drying furnaces and other equipment that uses a lot of energy.

Comparison of CO2 Emissions from Continuous Kilns by Year of Introduction

Changes in per unit of CO2 emissions from continuous kilns, a typical production facility

NGK Group Production Site Initiatives (Winner of the FY2024 Energy Conservation Grand Prize Award)

NGK ADREC won the Prize of Director General of Agency for Natural Resources and Energy (Industrial Field) in the Energy Conservation Best Practices Category at the FY2024 Energy Conservation Grand Prize Award sponsored by The Energy Conservation Center, Japan (ECCJ) as a result of its top-down energy conservation enhancement initiatives. Energy conservation patrols and energy conservation assessments provided the impetus for NGK ADREC to reduce its current waste, review its operating conditions and reorganize its equipment. Taking on these and other efforts led to an energy conservation effect that was then recognized by this award. We are aiming to roll out these efforts to other sites in the future.

Energy Conservation of Buildings

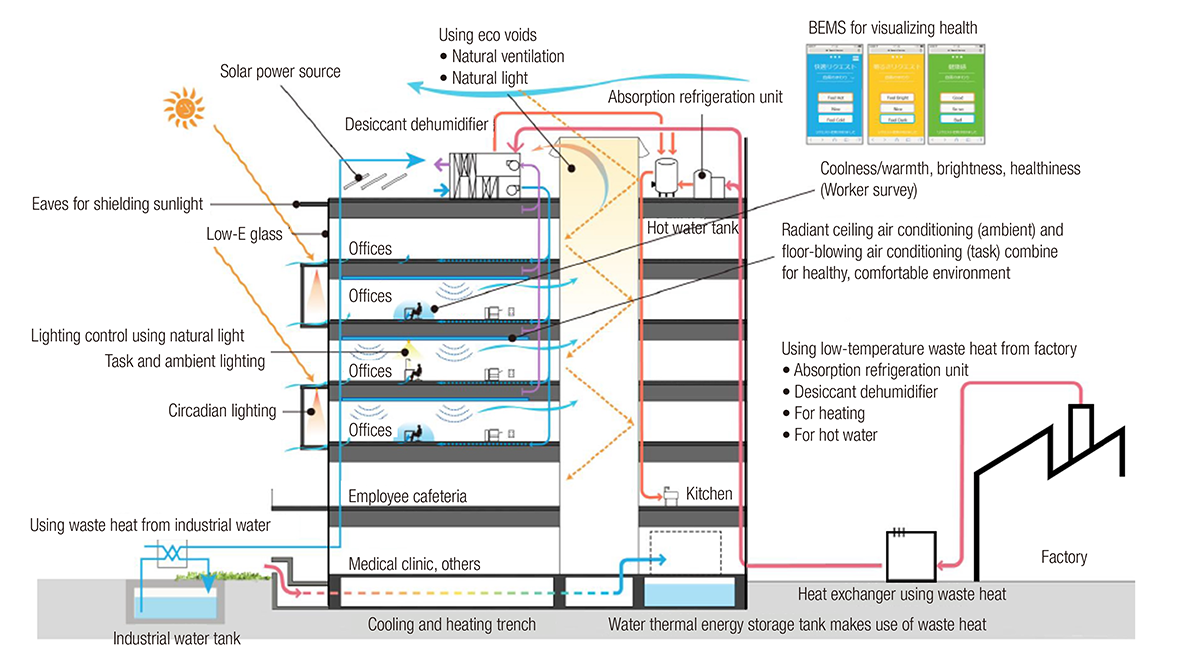

- Construction of a Zero Energy Building (ZEB)-orientated Office Facility

The NGK Group is proactively promoting energy conservation when constructing or renovating buildings. Completed in 2020, our new administrative/welfare wing in Mizuho, Nagoya incorporates high-efficiency equipment and renewable energy. In addition, it achieves significant energy savings by taking measures which give consideration to the location and other conditions such as the effective utilization of low-temperature exhaust heat from our adjacent plant and the use of natural ventilation and natural lighting. We constructed it as a ZEB-oriented office that halves CO2 emissions. It has been selected as one of the Ministry of Land, Infrastructure, Transport and Tourism’s Leading Sustainable Building Project (CO2 Reduction). Furthermore, this allowed us to achieve ZEB readiness in FY2022. In FY2023, it won the Prize of Director General of Agency for Natural Resources and Energy (Business Category) in the Best Practices Category at the FY2023 Energy Conservation Grand Prize Award sponsored by The Energy Conservation Center, Japan (ECCJ). We will continue to meet ZEB standards when constructing buildings in our group in the future.

New Administration/Welfare Wing

New Administration/Welfare Wing

- Energy Conservation Activities in Existing Buildings

In parallel with taking energy conservation measures when constructing or renovating buildings, we are also promoting energy conservation in our existing administrative facilities and offices. The main building in the Head Office district was completed in December 1992. It was originally designed as a facility with a high energy conservation performance level capable of high-precision air conditioning settings. Nevertheless, now that it has been in use for over 30 years, its energy-conservation effectiveness has gradually declined compared to more recent facilities. In light of this situation, the Back-office Department Energy Conservation Working Group launched an initiative aimed at further energy conservation effects in addition to existing management methods. First, we installed meters displaying the temperature, humidity and discomfort index in the offices on each floor. Furthermore, the top management personally sent a video message encouraging users of the facility to take actions with energy conservation in mind such as by regulating their body temperature with adjustments to their clothing. Moreover, facility managers now make fine adjustments to the air conditioning while checking the actual temperature and humidity. When requested by users to change the temperature, they respond appropriately upon checking the readings on the meters. As a result of these efforts, it was possible to reduce energy use by approximately 20% over three years from 2021 to 2024. We plan to continue and to improve upon these activities and to then roll them out to other buildings in the future.

Operation of Internal Carbon Pricing (ICP)

Internal carbon pricing (ICP) is a carbon price independently set and used within a company to promote decarbonization-focused investments and policies. The NGK Group began operating ICP in FY2022. We use it to evaluate the feasibility of introducing equipment. As in FY2023, we again set the ICP base price at 140 US dollars per metric ton of CO2 in FY2024. This is the carbon price (for developed countries) in FY2030 as expected by the International Energy Agency (IEA) that we refer to in setting the ICP. We have applied ICP to investment return calculations for the installation of waste heat utilization and photovoltaic power generation systems to reduce CO2 emissions. Going forward, we will pay attention to societal trends and start to consider further application of internal carbon charges.

Strategy 3: Promoting Technological Innovation (Fuel Conversion Working Group and CO2 Capture Working Group)

It is possible to reduce the CO2 emissions that arise from the indirect use of power and other forms of energy by introducing renewable energy. On the other hand, the firing process is necessary to manufacture the ceramic products that are one of the strengths of our company. We mainly use natural gas as the fuel in that process. That means direct emissions are higher than those of other businesses. Therefore, in addition to electrification, we are developing fuel conversion technologies using hydrogen, ammonia and similar. Our aim is to eliminate CO2 emissions from the fuels we use in the firing process.

Fuel Conversion Technology Development

We installed a mass production demonstration furnace in FY2022 toward the practical application of a kiln using a hydrogen burner. We are currently verifying the burner durability, the temperature distribution within the furnace and other aspects in the mass production demonstration furnace. In addition, we are confirming the quality in prototypes toward application to products.

Roadmap for the Mass Production Applications of Hydrogen and Ammonia

CO2 Capture Technology Development

We have introduced Carbon dioxide Capture, Utilization and Storage (CCUS) equipment to capture CO₂ from exhaust gas emitted by our plants and are proceeding with a demonstration of it in preparation for the progress of hydrogen and ammonia infrastructure development. We installed methanation equipment to synthesize captured CO2 and hydrogen and then generate methane, the main component of city gas, in FY2024. We are currently working on a demonstration of this equipment. We have completed a fuel experiment in a deodorization furnace using synthesized methane (albeit mixed with the main fuel). We plan to begin using it in September 2025.

CO2 Separation, Capture and Reuse Demonstration Experiment

Strategy 4: Expanding Use of Renewable Energy (In-house Photovoltaic Installation Working Group and Renewable Energy Procurement Working Group)

The NGK Group joined RE100 (100% Renewable Electricity) in 2022. We have committed to using renewable energy for all the power we use in our business by 2040. To achieve this target, we are systemically promoting the introduction of renewable energy such as with the installation of photovoltaic power generation systems and the procurement of renewable energy with Green Power Certificates and similar while being cognizant of the associated costs.

The installation of photovoltaic power generation systems, the procurement of renewable energy and other measures led to a reduction in CO2 by 7,000 metric tons in FY2024. In FY2025, we will continue to further promote initiatives to achieve a 50% renewable energy usage rate in the NGK Group.

In-house Photovoltaic Power Generation System Installation

We have promoted the installation of photovoltaic power generation systems in NGK CERAMIC DEVICE CO., LTD. (NCDK)'s Tajimi Plant, NGK CERAMICS SUZHOU CO., LTD. and other production sites in and outside Japan. We continued to install such systems at our Nagoya Site, NGK Ceramics Polska (ACP), one of our overseas production sites, and other locations in FY2024.

Demand Response Using NAS Batteries

Demand response is a mechanism in which consumers adjust their power usage to maintain a balance between supply and demand for power. NGK uses NAS batteries installed in its Nagoya, Chita, Komaki and other sites to release the power stored in storage batteries in line with the times when there is a lack of power of summer and winter. This contributes to alleviating the tight power supply-demand balance.

Procurement of Renewable Energy

Simply promoting energy conservation and introducing renewable energy within the NGK group is not sufficient to achieve our carbon neutrality targets. Accordingly, the NGK Group is promoting the procurement of renewable energy while comprehensively taking into consideration the local situation, costs and other factors. In addition to directly procuring energy from solar power plants, our procurement methods include those in which we acquire environmental value alone as Green Power Certificates separate to the power we use. As a part of these efforts, we first promoted procurement focused on our overseas production sites. We achieved 100% procurement of renewable energy-derived at all our manufacturing sites in Europe—NGK Ceramics Polska, NGK Ceramics Europe and NGK Berylco France—and our North American group company NGK-Locke, Inc. in FY2021.

Meanwhile, in terms of fuel, we are working to reduce our CO2 emissions by using carbon credits such as carbon neutral LNG at NGK’s Nagoya, Chita and Komaki sites as well as NGK CERAMIC DEVICE’s head office.

Furthermore, NGK Ceramics Polska will begin procuring power under a Virtual Power Purchase Agreement (VPPA) in FY2026. The company plans to procure this power for 10 years from April 2026. This is expected to contribute to a reduction in carbon dioxide (CO2) by approximately 940,000 metric tons over the 10 years of the agreement.

Status of the NGK Group’s Expansion in Use of Renewable Energy in Each Region (FY2024 Results)

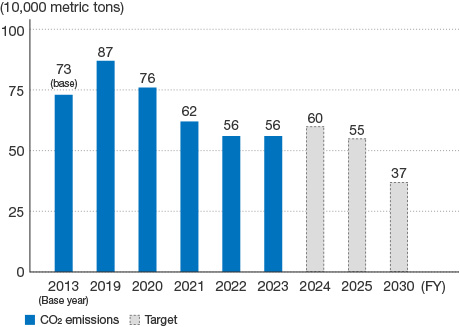

Targets and Achievements (Strategies 2 to 4)

We have worked to promote energy conservation activities, install photovoltaic power generation systems in the NGK Group, procure renewable energy, switch to carbon neutral LNG* and take other measures. As a result of these efforts, our actual CO2 emissions (Scope1 and 2) in FY2024 were 540,000 metric tons. That means we achieved our target of having 600,000 metric tons or less of CO2 emissions. We initially set a target of CO2 emissions of 550,000 metric tons for the final year of the 5-Year Plan we formulated in 2021. However, in light of the progress of our initiatives toward carbon neutrality, we have lowered that target to 500,000 metric tons of CO2 emissions. In FY2025, we will further promote the aforementioned initiatives as we did in FY2024.

The numerical values in the graph include the effect of carbon neutral LNG. Carbon neutral LNG is LNG that has been offset with CO2 credits and is considered to generate no CO2.

However, carbon neutral LNG is currently not eligible for credits under the Act on Rationalizing Energy Use and similar legislation.

Efforts to Achieve Carbon Neutrality throughout Our Entire Value Chain

In order to promote carbon neutrality, it is important to understand not only Scope1*1 and Scope2*2 CO2 emissions, but the Scope3*3 CO2 emissions in our value chain, and to work with suppliers and customers to reduce them. The NGK Group has acquired Science Based targets (SBT) certification for our targets to realize net-zero CO2 emissions and is working to reduce our emissions.

Carbon Neutral Targets Based on SBT Certification

We have set targets based on the net-zero standards given by the SBT initiative and acquired certification for them in FY2024.

Scope 1 and 2 Targets

| Year | Target |

|---|---|

| 2050 | Net zero |

| 2030 | 50% reduction in CO2 emissions compared to FY2013 |

Scope3 Targets

| Year | Target |

|---|---|

| 2050 | 90% or more reduction in CO2 emissions compared to FY2022 |

| 2030 | 25% reduction in CO2 emissions compared to FY2022 |

1 Scope1: Greenhouse gases directly emitted by a company

2 Scope2: Indirect emissions from the use of power and similar purchased from other companies

3 Scope3: Other indirect emissions generated throughout the value chain

NGK Acquires Certification under the Science Based Targets initiative (SBTi) Net-Zero Standard

Scope3 Reduction Initiatives

The NGK Group began tracking Scope3 CO2 emissions throughout our entire group in FY2022. We confirmed our Scope 3 emissions were 3.75 million metric tons in FY2024. Category 1 (purchased products and services) in Scope3 accounted for the most of these emissions at 2.02 million metric tons. This was followed by Category 11 (use of sold products) at 1.37 million metric tons. Therefore, we believe it is important to prioritize reducing emissions from these categories.

In light of this background, we set emission reduction targets based on the SBT initiative’s net-zero standards in FY2024. We are working to reduce emissions, including Scope3 emissions, throughout our entire value chain. The NGK Group places importance on cooperation with our suppliers. We began a survey concerning greenhouse gas emissions and reduction targets on 200 of our major suppliers in FY2024. We held a briefing session ahead of the survey to encourage the support and participation of as many suppliers as possible. We used the briefing session to share details of the NGK Group’s climate change initiatives. Together with this, we requested the cooperation of our suppliers in initiatives to reduce emissions and to provide information. Moreover, we are also striving to deepen cooperation with our suppliers through communication with them. For example, we respond individually to inquiries from our suppliers and exchange opinions with them aimed at the continuation of activities.

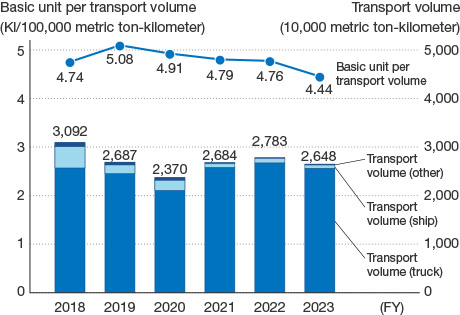

Carbon Neutrality through Life Cycle Assessments (LCAs) (LCA Working Group)

The life cycle assessment (LCA) is a quantitative evaluation method for the environmental impacts of products and services throughout their entire lifecycle (resource extraction – raw material production – product manufacturing – distribution/consumption – disposal/recycling). We believe it is important to track the CO2 emissions (Carbon Footprint of Products; CFP) for each NGK Group product in addition to the total amount of Scope1, Scope2 and Scope3 emissions to promote CO2 reduction throughout our entire value chain. The NGK Group set a target to calculate the CFP with LCAs for our main products in our fifth 5-year Environmental Action Plan. We started calculating the CFP based on ISO 14040 in FY2021. We identify processes with high CO2 emissions for our main products and new products and then work to reduce those emissions. We have conducted LCAs on our main products to identify the processes with a high environmental impact and to understand the benefits of improvements. In addition, we conduct LCAs on development products and new products in the product planning and design stages to provide products with lower environmental impact and greater competitiveness compared to other products and our existing products. We have learned from the LCA results on our major products that approximately 20% of all CO2 emissions occur during the raw material procurement stage, approximately 70% occur during the manufacturing stage and approximately 10% occur during the stage of transportation to our customers. Furthermore, approximately 50% of CO2 emissions are derived from power while approximately 30% are derived from fuel in the manufacturing stage. That has made it possible to quantitatively grasp the reduction effect when eliminating CO2 emissions from electricity and fuel.

Other Initiatives

100% Carbon-Neutral Performance Initiative

We helped to realize a 100% carbon-neutral performance held in Ena on December 3, 2024 by the Sukima Switch music unit. Ena Electric Power supplied CO2-free power derived from solar and hydroelectric power generation. Power stored in NAS batteries was used in the performance from the evening onward. Furthermore, the CO2 emissions from all the energy used in relation to the performance, including audience and staff transportation, accommodation, and merchandise manufacturing, were calculated based on an LCA and then offset using J-Credits derived from Ena Electric Power.

Participation in and Certification with Initiatives and External Organizations

Our Approach to Participation in External Organizations

The NGK Group is promoting efforts to realize net-zero CO2 emissions by actively participating in industry associations and initiatives that match our approach and course of action on measures against climate change. Moreover, we carefully review our participation in these external organizations to make sure that there are no significant deviations from NGK Group policy. If we find that there are significant discrepancies with our course of action, we will consider revising the details of our participation or even withdrawing from that organization. The Sustainability Management Dept. plays a central role and works with our relevant internal departments to consider the response in such a case.

Support for and Participation in Initiatives

Task Force on Climate-related Financial Disclosures (TCFD)

The NGK Group expressed our endorsement of the recommendations of the Task Force on Climate-related Financial Disclosures (TCFD), which was established by the Financial Stability Board (FSB), in 2020. We had been considering using the TCFD framework to resolve issues such as the risks and opportunities posed by climate change to the NGK Group’s business and to disclose the information necessary. We now disclose relevant information that we have analyzed based on scenarios in line with the four items recommended for disclosure by the TCFD: governance, strategy, risk management, and metrics and targets. We will continue to deepen our analysis and enhance information disclosures while promoting dialogue with stakeholders. Moreover, we will also clarify the climate change-related impact on our business. We will then take response strategies to ensure sustainable business growth.

Information Disclosures Based on TCFD Recommendations

Science Based Targets initiative (SBTi)

The NGK Group has acquired certification from the Science Based Targets initiative, an international certification organization, according to its net-zero standards for our greenhouse gas emission reduction targets. We are aiming to reduce greenhouse gas emissions by at least 90% compared to FY2022, the base year, throughout our entire value chain by 2050. We will aim to reduce Scope3 emissions by 25% compared to the base year by 2030 as a step to achieving this target. As a result, our net-zero target has been certified by the SBT initiative.

Science Based Targets initiative (SBTi)

RE100

RE100 (100% Renewable Electricity) is an international initiative comprised of companies aiming to cover the power they use in their business activities completely with renewable energy. The NGK Group joined RE100 in October 2022. The NGK Group has set carbon neutrality as one of the social issues we must address in our NGK Group Vision: Road to 2050. In the NGK Group Environmental Vision that we formulated together with the NGK Group Vision: Road to 2050, we have set a target of net-zero carbon dioxide (CO2) emissions by 2050. We are working to expand the use of renewable energy as one of our strategies to realize that target.