Sustainability

Environmental Management System (EMS)

The NGK Group promotes environmental conservation activities in accordance with our NGK Group Environmental Policy through initiatives pertaining to environmental management frameworks and the Environmental Management System (EMS) implemented by the entire Group working together.

Promotion System

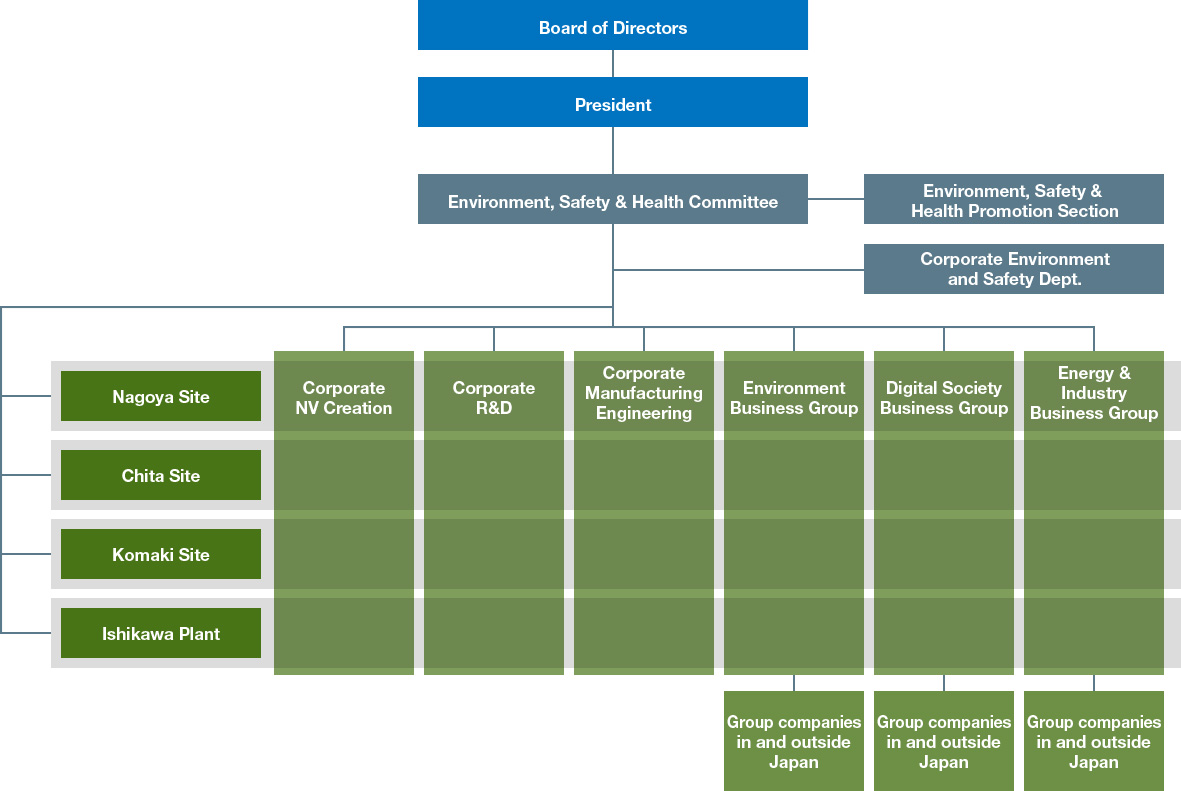

In addition to NGK’s environmental management systems at each site of Nagoya (headquarters, Atsuta/Mizuho), Chita, Komaki, and the Ishikawa Plant, we are promoting environmental management under the leadership of each business group to control environmental activities at all Group companies in and outside Japan. The decisions of the Environment, Safety and Health Committee are shared across the entire Group via the business groups so they can be incorporated into the business activities of each Group company. Annual liaison meetings are held for Group companies in Japan to promote unified environmental management for the entire Group. Meanwhile, personnel and business groups at headquarters cooperate to audit Group companies inside and outside Japan on a regular basis. Thus, we create interactive discussion and support opportunities to address issues facing each company.

Environmental Management Promotion System Diagram

Environment, Safety & Health Committee

The Environment, Safety & Health Committee handles both environmental management and safety and health management. Both kinds of management work are the same from the perspective of compliance, governance, and risk reduction, so we integrate their handling under a single committee. The committee is led by a Director and Managing Executive Officer, and meets at least twice a year. In addition, the chairperson may call ad-hoc meetings of the committee as necessary to make decisions on important matters. The details of committee meetings are also reported to the Board of Directors which provides oversight.

Governing Structure

| Chair | President appoints the chair in light of Executive Committee deliberations |

|---|---|

| Vice Chair | Appointed by Committee Chair |

| Members | Executive Vice President; Administrative staff with jurisdiction; Group Executives; General Managers; Director of each site (General Manager of Pollution Control; General Safety and Health Manager); others designated by the Committee Chair |

Environment, Safety & Health Promotion Section

Governing Structure

| Committee Chair | General Manager of Safety, Quality & Environment Dept. |

|---|---|

| Vice Chair | General Manager of Environment Business Group Safety, Quality Assurance & Environment Div.; General Manager of Digital Society Business Group Safety, Quality Assurance & Environment Dept.; General Manager of Energy & Industry Business Group Safety, Quality Assurance & Environment Dept.; General Manager of R&D Planning Dept., Corporate R&D; General Manager of M&E Planning Dept., Corporate Manufacturing Engineering; others designated by the Committee Chair |

Environmental Committees

In principle, committees of each NGK site (Nagoya Site [headquarters, Atsuta/Mizuho], Chita Site, Komaki Site, Ishikawa Plant) meet twice per year in each area. They thoroughly convey matters determined by the Environment, Safety & Health Committee, and communicate and discuss issues and topics in each area.

Environmental Management at Group Companies in and outside Japan

Business groups of NGK, including those at Group companies in and outside Japan, have environmental management systems for promoting environmental activities based on NGK Group Environmental Policy. NGK surveys environmental performance at Group companies and conducts audits to monitor their conformance to environmental laws and regulations. If problems are discovered, the causes and remedies are determined and disseminated throughout our Group companies. Moreover, at Group companies in Japan involved in manufacturing, annual liaison meetings are held in order to convey action policies and to share information on matters such as companies’ environmental management status and effective environmental initiatives.

Strengthening Global Environmental Management

The NGK Group promotes corporate activities that are in harmony with the environment. We are also building and implementing an environmental management system from a global perspective in order to actively fulfill our responsibility to address various societal challenges. As we continue our efforts aimed at lessening the environmental impact of our business activities, we are also preparing a system for complying with environmental laws and regulations, and increasing our level of global environmental management.

Efforts to Mitigate Environmental Risks Throughout the Group

All NGK Group manufacturing bases in and outside Japan have completed acquisition of ISO 14001 or third-party certifications meeting this standard, and are implementing environmental management in accordance with our environmental management system. NGK also shares information regarding changes in domestic environmental laws and regulations with Group companies in Japan and has created and implemented a structure to ascertain the status of responses to these changes. NGK headquarters is enhancing its ability to regularly ascertain the status of responses and management in terms of important legal and regulatory system revision information in the countries and regions where overseas Group companies are located.

In order to lessen the risk of environmental accidents and compliance violations, we are also promoting a shift from reactive response and recurrence prevention to preventive activities. As a measure for preventing incidents such as exceeding standards or failure to implement measures against accidents, we re-inspected things that are thought to pose a high environmental risk including handling of hazardous substances, registered equipment related to water quality, and the like. We then took corrective measures to address defects. Again, in FY2024 we performed re-inspections related to waste management, and moved forward with countermeasures.

Acquisition of Environmental Management System Certification

The NGK Group encourages the acquisition of ISO 14001 or third-party certifications (such as Eco Stage 2 or Eco Action 21 in Japan) that meet this standard to systematically and continuously develop its environmental conservation activities in line with NGK Group Environmental Policy.

Under this initiative, all Group companies, including those outside Japan, as well as the Nagoya, Chita, Komaki sites and Ishikawa plant, have received third party certification of their environmental management systems.

Environmental Management System Certification StatusAs of May 2025

| Category | Number of manufacturing sites | Number of sites certified | |

|---|---|---|---|

| NGK | 4 | 4 | |

| Group companies in Japan | Environment Business Group | 5 | 5 |

| Digital Society Business Group | 9 | 9 | |

| Energy & Industry Business Group | 5 | 5 | |

| Group companies outside Japan | Environment Business Group | 11 | 11 |

| Digital Society Business Group | 4 | 4 | |

| Energy & Industry Business Group | 3 | 3 | |

New production sites operating for less than two years are not covered

Environmental Audits

Every year, NGK conducts internal audits and external audits (surveillance audits and review audits) of the environmental management system at all Group sites in Japan and overseas, including Nagoya, Chita, Komaki, and Ishikawa.

In FY2024, there were no significant findings. In the event of a significant finding, the relevant department and Environment, Safety & Health Dept. work together to review and implement countermeasures, as well as inform the Environment, Safety & Health Committee in each area in an attempt to horizontally deploy these measures.

Significant Findings

Environmental Risk Management

At the NGK Group, each manufacturing site has individually established environmental management systems, and strives to preserve the environment and reduce environmental risks. The business group which oversees Group companies joins together with the Environmental Management Department at NGK headquarters to conduct yearly environmental audits of Group company manufacturing sites and help improve the level of environmental management of the NGK Group as a whole.

Regulatory Compliance

NGK conducts monitoring and assessments as well as vigorous control of exhaust and wastewater produced from its sites, observing relevant regulations and environmental preservation-related and other agreements with control authorities.

Additionally, we organize environmental management specialist seminars on a regular basis for all Group companies in Japan to keep responsible persons updated on related topics, thereby enhancing our capabilities to prevent environmental pollution. In FY2024, there was a case in which slurry containing product raw materials was discharged into the storm drainage system by a Group company in Japan. On top of implementing measures to prevent recurrence, we will promote their deployment laterally across the Group by disseminating information through the Environment, Safety & Health Committee.

Major Violations

Environmental Patrols and Emergency Response Drills

NGK implements environmental patrols in line with annual plans to prevent environmental pollution and conducts response drills based on emergency scenarios to minimize damage.

In FY2024, environmental patrols were conducted at the Nagoya, Chita, and Komaki sites and the Ishikawa Plant to prevent atmospheric and water pollution, ensure the appropriate management of chemical substances, and suppress noise and vibrations. Response drills based on emergency scenarios were also conducted at these four areas. Going forward, NGK will continue to proactively engage in patrols and drills in an attempt to improve operational methods and mitigate environmental risks.

Activities Conducted in FY2024

Environmental patrols

| District | Air | Water | Noise/Vibration | Chemical substances |

|---|---|---|---|---|

| Nagoya | 4 | 2 | 4 | 2 |

| Chita | 1 | 1 | 1 | 1 |

| Komaki | 2 | 2 | 1 | 1 |

| Ishikawa | 2 | 2 | 2 | 2 |

Emergency response drills

| District | Air | Water | Noise/Vibration | Chemical substances |

|---|---|---|---|---|

| Nagoya | 3 | 2 | - | 2 |

| Chita | 6 | 5 | - | - |

| Komaki | 8 | 16 | - | - |

| Ishikawa | 6 | 2 | - | 2 |

Note: “-” indicates emergency response drills were considered of low importance and not conducted.